UNS S31803 duplex stainless steel pipe has a unique duplex structure. It has composed of two phases of austenite and ferrite. This duplex structure gives the steel pipe excellent comprehensive performance. Compared with traditional austenitic stainless steel, it has higher strength. UNS S31803 steel pipe plays an Duplex stainless steel pipe can withstand higher internal pressure without deformation or rupture.

UNS S31803 duplex stainless steel pipe can be used to transport acidic and alkaline solutions, etc. Due to its corrosion resistance, it can maintain good appearance and structural integrity under marine climate conditions.

Specification of UNS S31803 Duplex Stainless Steel Pipes

| Processing Method | Seamless and Welded |

| Size Range | 1/8” – 48” / DN6 – 750 |

| Thickness Schedule | SCH10 SCH20 STD SCH40 SCH60 SCH80 SCHXS SCH100 SCH120 SCH140 SCH160 SCHXXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.19,ASTM A789, ASTM A790, ASTM A928, ASME SA789, |

| Surface Treatment | Polish , Mirror , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A790 S32205, S31803, 32750, 32760, S32550 |

| Pipes Ends | Plain Ends / Beveled Ends |

The Difference Between UNS S31803 and S32205

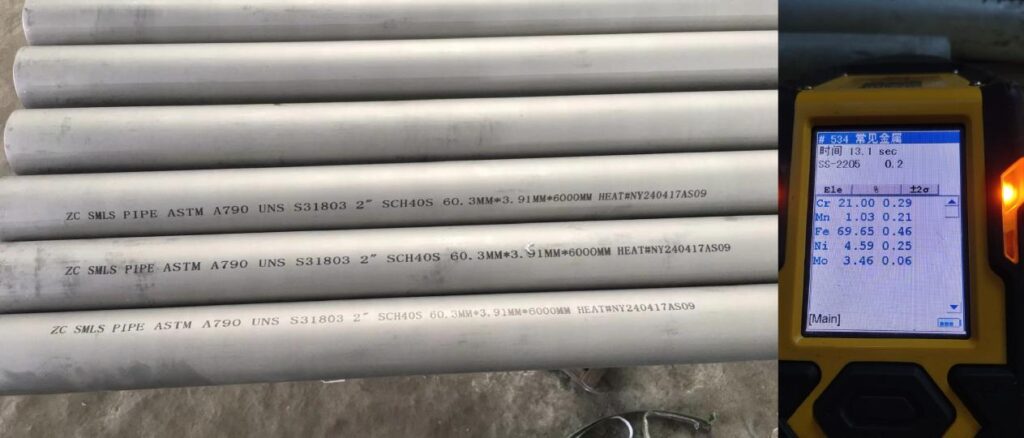

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A790 S31803 | MIN | 4.5 | 21.00 | 2.50 | 0.08 | |||||

| MAX | 0.03 | 2.00 | 0.03 | 0.02 | 1.00 | 6.5 | 23.00 | 3.50 | 0.20 | |

| ASTM A790 UNS S32205 | MIN | 4.50 | 22.00 | 3.00 | 0.14 | |||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 |

The chromium content of S31803 is roughly between 21 and 23%. The chromium content of S32205 duplex stainless steel pipe is about 22 to 23%. The relatively higher chromium content of S2205 helps improve its corrosion resistance in more severe environments.

The molybdenum content of S31803 is around 2.5 – 3.5%, while the molybdenum content of S2205 is different. The difference in molybdenum content will affect the material’s resistance to pitting and crevice corrosion. In addition, other trace elements and their proportions in the two alloys will also cause differences in performance.

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A815 UNS 31803 | 620 min | 450 min | 20 min | 290 max |

| ASTM A815 WPS 32205 | 655min | 450min | 20 min | 290 max |

As duplex stainless steels evolved, their initial specification was captured as UNS S31803. However, many leading manufacturers have been producing this grade to the upper end of the permissible specification. This reflects their desire to maximize the corrosion performance of the alloy, aided by the development of the AOD steelmaking process, which allows for tighter control of composition. In addition, it also allows for the level of nitrogen additions to be influenced, rather than just being present as a background element.

As a result, the highest performing duplex grades seek to maximize the levels of chromium (Cr), molybdenum (Mo), and nitrogen (N). Based on the formula PREN = %Cr + 3.3 %Mo + 16 % N, the difference between a duplex alloy that meets the bottom of the specification and one that reaches the top of the specification can be several pips.

In order to differentiate duplex stainless steels produced at the high end of the composition range, a further specification was introduced, UNS S32205. Duplex stainless steels manufactured under the S32205 heading will fully comply with the S31803 heading, while the reverse is not true. Therefore, the S32205 can be dual-certified as an S31803.

Application of UNS S31803 Duplex Stainless Steel Pipe

Oil and gas industry

UNS S31803 duplex stainless steel pipe is widely used in the extraction, transportation and processing of oil and gas. On offshore oil platforms, pipes are used to transport crude oil, natural gas and various chemical additives. In long-distance oil and gas pipelines on land, its high strength and corrosion resistance can ensure the safe operation of pipelines under complex geological and environmental conditions.

Chemical industry

The chemical production process involves the transportation of various corrosive media, and UNS S32205 steel pipes are an ideal choice. Whether it is acidic, alkaline or salt-containing media, it can do the job.

Building and infrastructure fields

In the field of construction, UNS S31803 duplex stainless steel pipe can be used for water supply and drainage pipes in building structures, especially in some buildings with high requirements for corrosion resistance, buildings near sewage treatment plants, etc. In terms of infrastructure, such as underground comprehensive pipe corridors in cities, pipes used to transport various media, their good mechanical properties and corrosion resistance can meet the requirements of long-term use.

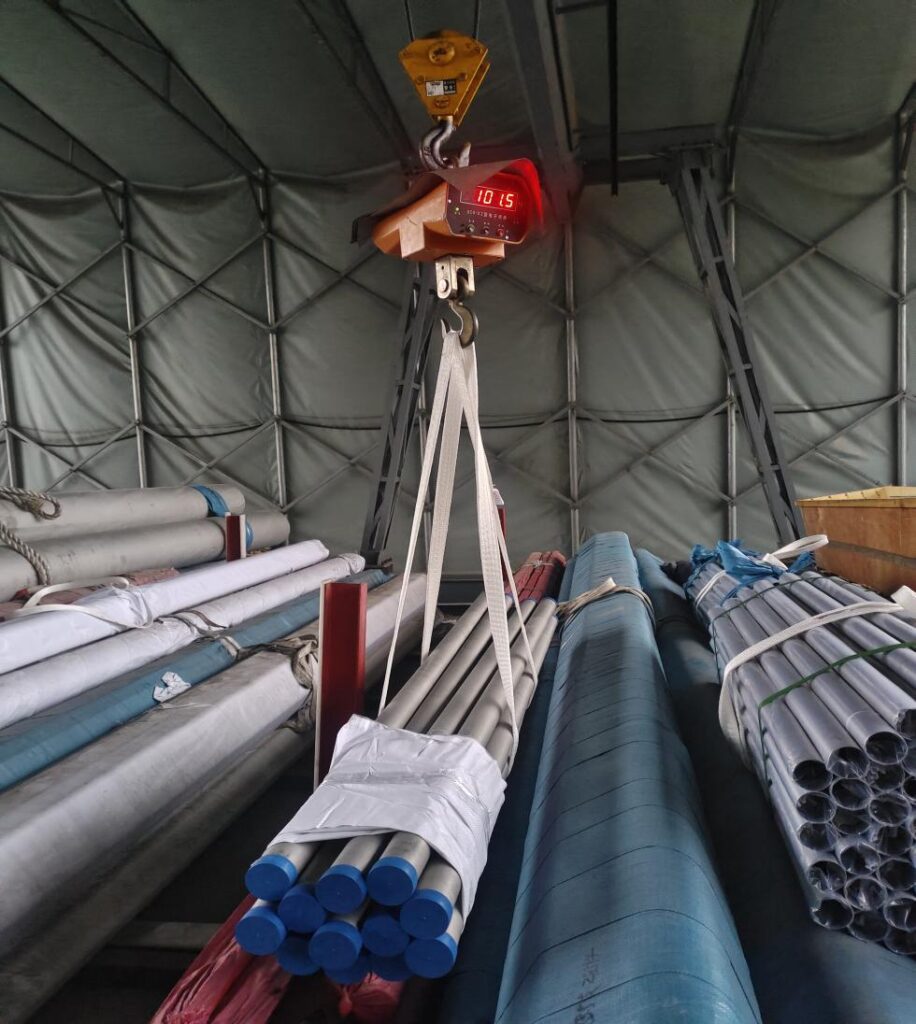

Importance of Weighing Steel Pipes

In the production and sales of steel pipes, weighing is an important means to ensure quality. For manufacturers, accurate weighing can accurately control the weight of steel pipes, thereby reflecting whether the wall thickness, length and other dimensions of the steel pipes meet the standards. In the purchase and sale of steel pipes, weighing is a key step in determining the quantity of goods. Whether it is domestic or international trade, steel pipe transactions based on weight are very common. Accurate weighing results can ensure fair transactions between buyers and sellers.

When the number of UNS S31803 duplex stainless steel pipe is large, they are usually weighed in bundles or batches. First, the whole bundle or batch of steel pipes is hoisted onto the scale, and the weight is also recorded after the reading stabilizes. However, in this case, the weight of the bundling materials needs to be taken into account. If the bundling materials are heavy, the weight of the bundling materials needs to be weighed separately and subtracted from the total weight to obtain the accurate net weight of the steel pipes.