Stainless steel forged fittings are an important type of industrial pipeline fittings, mainly made of stainless steel materials. It have excellent corrosion resistance, high temperature resistance, and mechanical properties. There are various types of stainless steel forged fittings, mainly used for connecting and transmitting fluids or gas media, and widely used in multiple industries such as petroleum, chemical, power, pharmaceuticals, and food.

According to the Connection Method: Socket Weld Fittings and Threaded Fittings

Stainless steel forged pipe fittings require multiple processes, including material selection, forging, heat treatment, mechanical processing, and inspection. These fittings typically have high dimensional accuracy and surface quality, with a wide variety of fittings that can meet strict engineering requirements and usage environments.

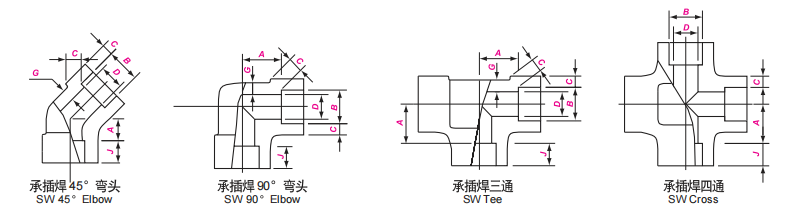

Socket weld fittings include: socket elbow, socket tee, socket cross, socket coupling, socket cap, socket boss,socket union;

Size range: 1/8 inch -4 inche;

Pressure range: Class 3000 6000 9000

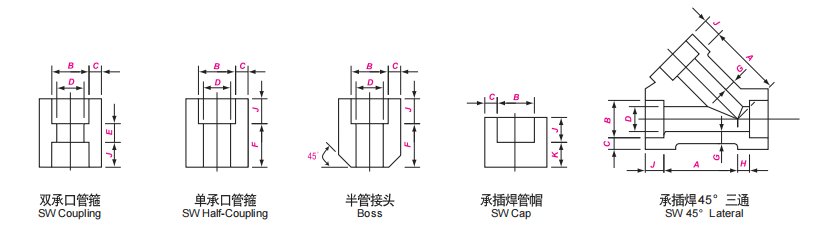

Threded fittings include: threaded 45 degree elbow, threaded 90 degree elbow, threaded tee, threaded cross, male and female threaded 90 degree elbow, threaded coupling, threaded boss, threaded cap, threaded plug, threaded bushing, threaded union, etc.

Size range: 1/8 inch -4 inch;

Pressure range: Class 2000 3000 6000

ASME B16.11 Types and Dimension of Stainless Steel Forged Fittings

The production standards for stainless steel forged fittings include ASME B16.11; MSS SP-83; MSS SP-97; MSS SP-95, etc. Among them, ASME B16.11 production standard is the most widely used. The ASME B16.11 standard is a production standard for forged high-pressure fittings published by the American Standards Institute. Specifically, the ASME B16.11 standard has detailed requirements for the material, size, shape, pressure rating, tolerance range, and other aspects of high-pressure forged fittings.

Types of Stainless Steel Socket Weld Fittings

Dimension

| Nominal Size | Socket Bore Dia | Bore Dia.of Fitings | Socket Wall Thickness | Body Wal | Depth of Socket | Center to Bottom of Socket | |||||||||||||||

| DN | NPS | B | D | C | Gmin | J mim | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°Elbow Tee Cross | 45°Elbow | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 11.0 | 11.0 | 8 | 8 | ||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 11.0 | 13.5 | 8 | 8 | ||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 13.5 | 15.5 | 8.0 | 11.0 | ||||||

| 15 | 1/2 | 21.9 | 15.0 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 |

| 32 | 1-1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 |

| 40 | 1-1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 |

| 65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16.0 | 41.0 | 28.5 | ||||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | ||||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | ||||||||||||

Types of Stainless Steel Socket Weld Fittings

Dimension

| Nominal Size | Socket Bore Dia | Bore Dia.of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Laying Lengths | Laying Lengths | End Wall Thickness | Center to Bottom of Socket | |||||||||||||||

| DN | NPS | B | D | C | n | min | E | F | Kmin | A | H | |||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 3000 | 6000 | |||||||||

| ave | min | ave | min | ave | min | |||||||||||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.3 | 4.6 | 4.01 | 3.02 | 3.68 | 9.5 | 6.5 | 16.0 | 4.8 | 6.4 | |||||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.5 | 5.03 | 4.37 | 3.2 | 4.01 | 9.5 | 6.5 | 17.5 | 4.8 | 6.4 | 37 | 9.5 | |||||||

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 9.5 | 22.5 | 6.4 | 7.9 | 11.2 | 41 | 51 | 9.5 | 11 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 9.5 | 24 | 6.4 | 7.9 | 12.7 | 51 | 60 | 11 | 13 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 12.5 | 28.5 | 9.6 | 11.2 | 14.2 | 60 | 71 | 13 | 16 |

| 32 | 1-1/4 | 42.8 | 34.3 | 42.1 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.7 | 12.5 | 12.5 | 30 | 9.6 | 11.2 | 14.2 | 71 | 81 | 16 | 17 |

| 40 | 1-1/2 | 48.9 | 40.1 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 12.5 | 32 | 112 | 12.7 | 15.7 | 81 | 98 | 17 | 21 | |

| 50 | 2 | 61.2 | 51.7 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16 | 19 | 41 | 12.7 | 15.7 | 19 | 98 | 151 | 21 | 30 | |

| 65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16 | 19 | 43 | 15.7 | 19 | 151 | 30 | |||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.3 | 7.62 | 16 | 19 | 44.5 | 19 | 22.4 | 184 | 57 | |||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19 | 19 | 48 | 22.4 | 28.4 | 201 | 66 | |||||||||||

Tolerance

| TOLERANCES FOR SW FITTINGS | ||||||||||

| Nominal Size | Aa Fttings | Ebows, Tees, Crosses | Couping | Half- Couplings | Reducer Inserts | Unions | ||||

| Socket Bore Dia | Bore Dia.of Fittings | Center to Bottom of Socket | Laying Lengths | Laying Lengths | Laying Length | Shank Dia | Length | Laying Length | ||

| DN | NPS | B | D | A,H | E | F | A | SD | SL | E |

| 6-8 | 1/8-1-1/4 | +0.4 0 | +1.5 0 | ±1.0 | ±1.5 | ±1.0 | +1.5 0 | ±0.25 | 0 -1.5 | ±1.5 |

| 10-20 | 3/8-3/4 | +0.4 0 | +1.5 0 | ±1.5 | ±3.0 | ±1.5 | +1.5 0 | ±0.25 | 0 -1.5 | ±3.0 |

| 25-40 | 1-1-1/2 | +0.4 0 | +1.5 0 | ±2.0 | ±4.0 | ±2.0 | +2.0 0 | ±0.25 | 0 2.0 | ±4.0 |

| 50 | 2 | +0.5 0 | +1.5 0 | ±2.0 | ±4.0 | ±2.0 | +2.0 0 | ±0.5 | 0 2.0 | ±4.0 |

| 65-80 | 2-1/2-3 | +0.5 0 | +3.0 0 | ±2.5 | ±5.0 | ±2.5 | +2.5 0 | +0.5 | 0 2.5 | ±5.0 |

| 100 | 4 | +0.5 0 | +3.0 0 | ±2.5 | ±5.0 | ±2.5 | +2.5 0 | ±0.7 | 0 -2.5 | |

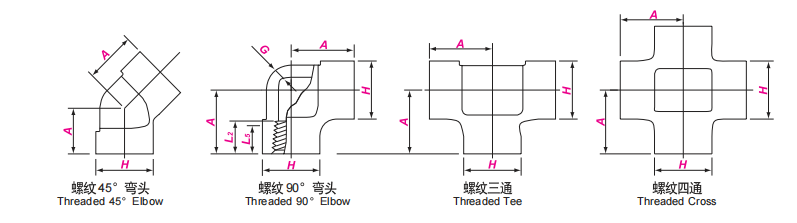

Tyeps of Threaded Forged Fittings

Dimension

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||||||

| DN | NPS | A | H | G min | min | mim | |||||||||

| 90 Ebows Tees Crosses | 45 Elbows | ||||||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

| 6 8 10 | 1/8 1/4 3/8 | 21 21 25 | 21 25 28 | 25 28 33 | 17 17 19 | 17 19 22 | 19 22 25 | 22 22 25 | 22 25 33 | 25 33 38 | 3.18 3.18 3.18 | 3.18 3.30 3.51 | 6.35 6.60 6.98 | 6.4 8.1 9.1 | 6.7 10.2 10.4 |

| 15 20 25 | 1/2 3/4 1 | 28 33 38 | 33 38 44 | 38 44 51 | 22 25 28 | 25 28 33 | 28 33 35 | 33 38 46 | 38 46 56 | 46 56 62 | 3.18 3.18 3.68 | 4.09 4.32 4.98 | 8.15 8.53 9.93 | 10.9 12.7 14.7 | 13.6 13.9 17.3 |

| 32 40 50 | 1-1/4 1-1/2 2 | 44 51 60 | 51 60 64 | 60 64 83 | 33 35 43 | 35 43 44 | 43 44 52 | 56 62 75 | 62 75 84 | 84 102 | 3.89 4.01 4.27 | 5.28 5.56 7.14 | 10.59 11.07 12.09 | 17.0 17.8 19.0 | 18.0 18.4 19.2 |

| 65 80 100 | 2-1/2 3 4 | 76 86 106 | 83 95 114 | 95 106 114 | 52 64 79 | 52 64 79 | 64 79 79 | 92 109 146 | 102 121 152 | 121 146 152 | 5.61 5.99 6.55 | 7.65 8.84 11.18 | 15.29 16.64 18.67 | 23.6 25.9 27.7 | 28.9 30.5 33.0 |

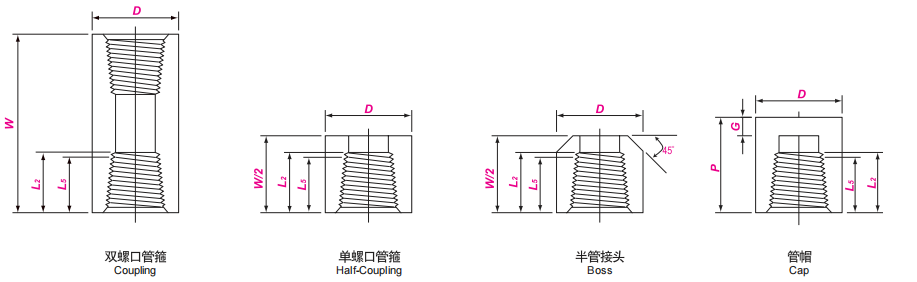

Tyeps of Threaded Forged Fittings

Dimension

| Nominal Size | End-to-End | End-to-End | Outside Diameter | End Wall | Length of Thread | |||||

| DN | NPS | W | P | D | G min | L5 min | L2 min | |||

| 3000&6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 8 10 | 1/8 1/4 3/8 | 32 35 38 | 19 25 25 | 27 27 | 16 19 22 | 22 25 32 | 4.8 4.8 4.8 | / 6.4 6.4 | 6.4 8.1 9.1 | 6.7 10.2 10.4 |

| 15 20 25 | 1/2 3/4 1 | 48 51 60 | 32 37 41 | 33 38 43 | 28 35 44 | 38 44 57 | 6.4 6.4 9.7 | 7.9 7.9 11.2 | 10.9 12.7 14.7 | 13.6 13.9 17.3 |

| 32 40 50 | 1-1/4 1-1/2 2 | 67 79 86 | 44 44 48 | 46 48 51 | 57 64 76 | 64 76 92 | 9.7 11.2 12.7 | 11.2 12.7 15.7 | 17.0 17.8 19.0 | 18.0 18.4 19.2 |

| 65 80 100 | 2-1/2 3 4 | 92 108 121 | 60 65 68 | 64 68 75 | 92 108 140 | 108 127 159 | 15.7 19.0 22.4 | 19.0 22.4 28.4 | 23.6 25.9 27.7 | 28.9 30.5 33.0 |

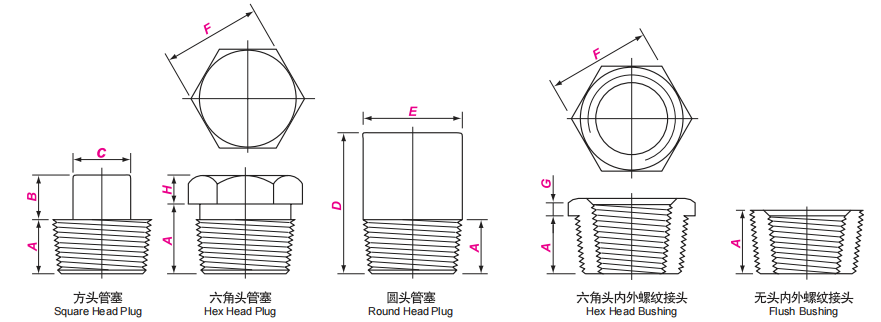

Tyeps of Threaded Forged Fittings

Dimension

| Nominal Size | Leng | Square Height | Width Flats | Head Diameter | Length | Hex Height | Hex Height | Hex Width Flats | |

| DN | NPS | A min | B min | C min | E nom | D mim | H min | G min | F nom |

| 6 8 10 | 1/8 1/4 3/8 | 10 11 13 | 6 6 8 | 7 10 11 | 10 14 18 | 35 41 41 | 6 6 8 | / 3 4 | 11 16 18 |

| 15 20 25 | 1/2 3/4 1 | 14 16 19 | 10 11 13 | 14 16 21 | 21 27 33 | 44 44 51 | 8 10 10 | 5 6 6 | 22 27 36 |

| 32 40 50 | 1-1/4 1-1/2 2 | 21 21 22 | 14 16 18 | 24 28 32 | 43 48 60 | 51 51 64 | 14 16 18 | 7 8 9 | 46 50 65 |

| 65 80 100 | 2-1/2 3 4 | 27 28 32 | 19 21 25 | 36 41 65 | 73 89 114 | 70 70 76 | 19 21 25 | 10 10 13 | 75 90 115 |

Tolerance

| TOLERANCES FOR THRD FITTINGS | ||||

| Nominal Size | Ebows Tees Crosses | Couplings | Half couplings | |

| Center-to-End | End-to-End | End-to-End | ||

| D N | NPS | A、J | W | W/2 |

| 6-8 | 1/8-1/4 | ±1.0 | ±1.0 | ±1.0 |

| 10-20 | 3/8-3/4 | ±1.5 | ±1.5 | ±1.5 |

| 25-50 | 1-2 | ±2.0 | ±2.0 | ±2.0 |

| 65-100 | 2-1/2-4 | ±2.5 | ±2.5 | ±2.5 |

Class of The Stainless Steel Forged Fittings VS Grade of the Connecting Pipes

| Joint Type | Class | Grade of Conneding Pipes | Joint Type | Class | Grade of Connecting Pipes |

| SW | 3000 | Sch80、XS | THRD | 2000 | Sch80、XS |

| 6000 | Sch160 | 3000 | Sch160 | ||

| 9000 | XXS | 6000 | XXS |

Shape

| Stainless Steel Elbow – Socket Weld and Screwed Type. ASME B16.11 & BS3799. |

| Stainless Steel Threaded Plug and Bushing. |

| Stainless Steel Nipple – Screw, Swage and Hexagonal Nipple. |

| Stainless Steel Cap – BSP & NPT Threaded Cap and Socket Weld Cap. |

| Union – 316 & 304 Stainless Steel Union in BSP, NPT and SW Type. |

| Stainless Steel Tee – Equal and Reducing Type in Socket Weld and Threaded. ASME B16.11 & BS3799 Standard. |

| Stainless Steel Pipe Coupling – Socket Weld and Threaded Full & Half Coupling. Available in Class 2000, 3000, 6000 and 9000. |

Material Types of Stainless Steel Forged Fittings

Stainless steel forged fittings are high-quality and high-performance pipeline connectors widely used in pipeline systems that need to withstand high temperatures and pressures in industries such as oil, natural gas, chemical, and power. The American standard material standard for stainless steel forged fittings corresponds to ASTM A182, and common material types include stainless steel F304/316; Duplex stainless steel F51/F53, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

Characteristics of Stainless Steel Fittings

Steel pipe fittings are basically used for piping and tubing systems to connect and change direction of the flow that conveys liquid, gas, and occasionally solid materials. Stainless steel pipes & fittings are strong and durable metal which is manufactured as an alloy of chromium and steel. There are various characteristics as following:

· Corrosion resistant

· Highly durable

· Lightweight

· Low maintenance

· Long service life

As a high-quality and high-performance pipe fitting, stainless steel forged fittings have a wide range of application prospects. When selecting and using forged fittings, attention should be paid to their quality and performance to ensure the safety, stability, and efficiency of fluid transportation, providing reliable guarantees for fluid transportation systems in various industries.