Stainless steel equal tee is commonly used pipe fittings in pipeline systems. They are mainly used at the connections of pipeline systems and play a role in changing direction, converging, or diverting flow. Stainless steel tees are an important type of pipeline connector, and their excellent performance and wide range of applications make them an indispensable part of pipeline systems.

According to the shape, stainless steel tees can be divided into equal tee and reducing tee.

Stainless steel Equal tee with the same outer diameter for main and branch pipes. Reducing tee refer different diameters between the main and branch pipes.In this article,we will introduce stainless steel equal tee.

How to Classify Stainless Steel Equal tee

Stainless steel equal tee can be classified according to different connection methods. Such as butt weld tee, threaded tee and socket tee.

Stainless Steel Butt Weld Tee

Stainless steel butt weld tees are pipe fittings that connect the main and branch pipes through welding, thereby achieving branch connections in the pipeline system. Due to its good sealing performance at the welded joints and low risk of leakage, it is widely used in various pipeline systems.

| Shape Type | Equal Tee and Reducing Tee |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409, ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, DIN2605/2615/2616/2617, EN10253 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347, 904L, A815 S32205, S31803, 32750, 32760 |

Dimension of ASME B16.9 Butt Weld Tee

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD1 X OD2 | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1-1/4 | 42.2 | 48 | 48 |

| 40 | 1-1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2-1/2 | 73.0 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 90 | 3-1/2 | 101.6 | 95 | 95 |

| 100 | 4 | 114.3 | 105 | 105 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273.0 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457.0 | 343 | 343 |

| 500 | 20 | 508.0 | 381 | 381 |

| 550 | 22 | 559.0 | 419 | 419 |

| 600 | 24 | 610.0 | 432 | 432 |

| 650 | 26 | 660.0 | 495 | 495 |

| 700 | 28 | 711.0 | 521 | 521 |

| 750 | 30 | 762.0 | 559 | 559 |

| 800 | 32 | 813.0 | 597 | 597 |

| 850 | 34 | 864.0 | 635 | 635 |

| 900 | 36 | 914.0 | 673 | 673 |

| 950 | 38 | 965.0 | 711 | 711 |

| 1000 | 40 | 1016.0 | 749 | 749 |

| 1050 | 42 | 1067.0 | 762 | 711 |

| 1100 | 44 | 1118.0 | 813 | 762 |

| 1150 | 46 | 1168.0 | 851 | 800 |

| 1200 | 48 | 1219.0 | 889 | 838 |

| 1300 | 52 | 1321.0 | 965 | 914 |

| 1400 | 56 | 1422.0 | 1041 | 965 |

| 1600 | 64 | 1626.0 | 1194 | 1092 |

| 1700 | 68 | 1727.0 | 1270 | 1168 |

| 1800 | 72 | 1829.0 | 1320 | 1245 |

| 1900 | 76 | 1930.0 | 1422 | 1320 |

| 2000 | 80 | 2032.0 | 1499 | 1397 |

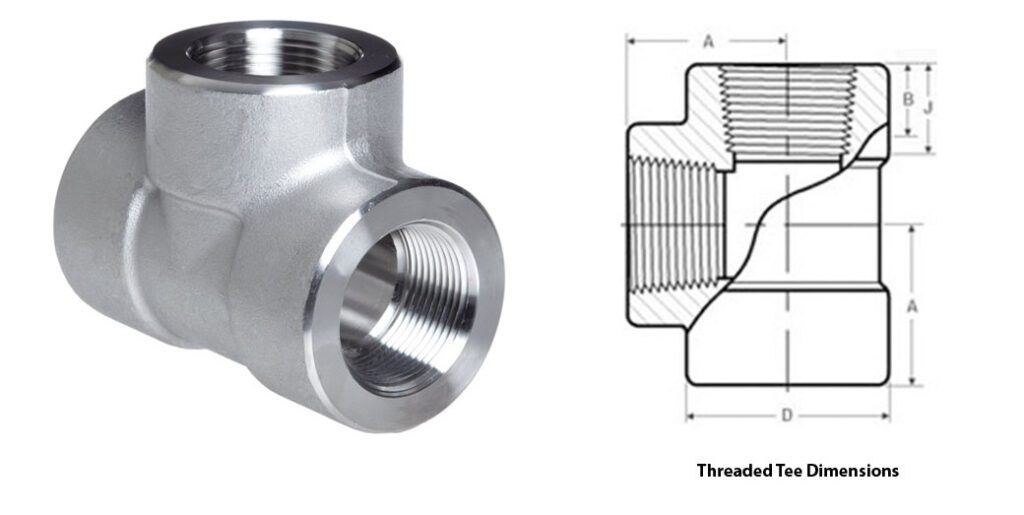

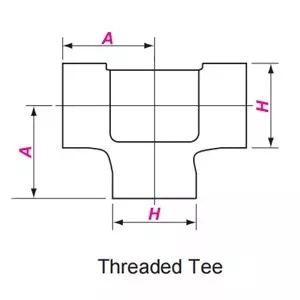

Stainless Steel Threaded Tee

Stainless steel threaded tee is a pipeline accessory made of stainless steel material forged and connected through threaded connection. It’s characteristics include strong corrosion resistance, easy installation, low maintenance cost. They are suitability for small diameter high-pressure pipeline systems below 4 inches.

| Type | Equal Tee and Reducing Tee |

| Size | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Class | Class 2000, 3000, 6000 |

| Grade | ASTM A182 F304/F304L/F316/F316L/F321/F347 |

Dimension of ASME B16.11 Threaded Tee

| DN | NPS | A | H | ||||

| 2000LB | 3000LB | 6000LB | 2000LB | 3000LB | 6000LB | ||

| 6 | 1/8 | 21 | 21 | 25 | 22 | 22 | 25 |

| 8 | 1/4 | 21 | 25 | 28 | 22 | 25 | 33 |

| 10 | 3/8 | 25 | 28 | 33 | 25 | 33 | 38 |

| 15 | 1/2 | 28 | 33 | 38 | 33 | 38 | 46 |

| 20 | 3/4 | 33 | 38 | 44 | 38 | 46 | 56 |

| 25 | 1 | 38 | 44 | 51 | 46 | 56 | 62 |

| 32 | 1-1/4 | 44 | 51 | 60 | 56 | 62 | 75 |

| 40 | 1-1/2 | 51 | 60 | 64 | 62 | 75 | 84 |

| 50 | 2 | 60 | 64 | 83 | 75 | 84 | 102 |

| 65 | 2-1/2 | 76 | 83 | 95 | 92 | 102 | 121 |

| 80 | 3 | 86 | 95 | 106 | 109 | 121 | 146 |

| 100 | 4 | 106 | 114 | 114 | 146 | 152 | 152 |

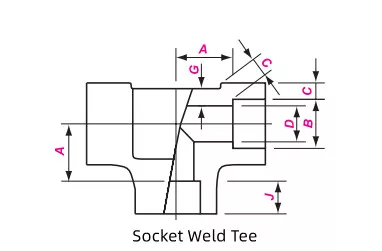

Stainless Steel Socket Weld Tee

The socket connection method makes the installation process of stainless steel socket tees relatively simple. After inserting the connecting fittings into each end of the tee, they can be fixed by welding or fusion. Without the need for complex processes and tools, improving installation efficiency.

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″- 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000, 6000, 9000. |

| Stainless Steel | ASTM A182 F304 / 304L / 304H, 316 / 316L, 321, 310S, 317, 347, 904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Dimension of ASME B16.11 Socket Weld Tee

| DN | NPS | B | C | A | G | |||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 11.0 | 11.0 | – | 2.41 | 3.15 | – |

| 8 | 1/4 | 14.3 | 3.78 | 3.30 | 4.60 | 4.01 | – | – | 11.0 | 13.5 | – | 3.02 | 3.68 | – |

| 10 | 3/8 | 17.7 | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 13.5 | 15.5 | – | 3.20 | 4.01 | – |

| 15 | 1/2 | 21.9 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 15.5 | 19 | 25.5 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 27.3 | 4.09 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 19 | 25.5 | 28.5 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 34.0 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 22.5 | 27.0 | 32.0 | 4.55 | 6.35 | 9.09 |

| 32 | 11/4 | 42.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 27.0 | 32.0 | 35.0 | 4.85 | 6.35 | 9.70 |

| 40 | 11/2 | 48.9 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 | 32.0 | 38.0 | 38.0 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 38.0 | 41.0 | 54.0 | 5.54 | 8.74 | 11.07 |

| 65 | 21/2 | 73.9 | 8.76 | 7.62 | – | – | – | – | 41.0 | – | – | 7.01 | – | – |

| 80 | 3 | 89.9 | 9.52 | 8.30 | – | – | – | – | 57.0 | – | – | 7.62 | – | – |

| 100 | 4 | 115.5 | 10.69 | 9.35 | – | – | – | – | 66.5 | – | – | 8.56 | – | – |

Material Feature of Stainless Steel

Stainless steel tees are produced using stainless steel as the raw material. Common stainless steel materials include SS304, SS316, SS321, etc. At the same time, its environmental and health characteristics also meet the requirements of sustainable development in modern society.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| SS304L | MIN | 8.00 | 18.00 | \ | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | \ | \ | |

| SS316L | MIN | 10.00 | 16.00 | 2.00 | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | \ | |

| SS317L | MIN | 11.00 | 18.00 | 3.00 | \ | |||||

| MAX | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 15.00 | 20.00 | 4.00 | \ | |

| SS321 | MIN | 9.00 | 17.00 | \ | \ | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 | \ | 0.10 | |

| SS347 | MIN | 9.00 | 17.00 | \ | \ | |||||

| MAX | 0.080 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 19.00 | \ | \ |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A312 TP304L | 485 min | 170 min | 35 min |

| ASTM A312 TP316L | 485 min | 170 min | 35 min |

| ASTM A312 TP317L | 515 min | 205 min | 35 min |

| ASTM A312 TP321 | 515 min | 205 min | 35 min |

| ASTM A312 TP347 | 515 min | 205 min | 35 min |

Application

Raw Material Transportation

Chemical Process Transportation

HVAC System

Water Supply System

Drainage System

Sewage Treatment System

Fresh Water System

Fire Protection System

Automotive Piping

Air Conditioning System

Food Processing

Stainless steel equal tees are widely used in multiple industries. Meanwhile, its diverse sizes and specifications, as well as flexible connection methods, also meet the needs of different pipeline systems.