Stainless steel butt weld fittings are widely used in construction, industry, and other fields. They are made of stainless steel material and connected to pipeline systems through welding. It’s excellent corrosion resistance and wear resistance, high strength and high temperature performance, play an important role in pipeline systems.

Stainless steel butt weld fittings are connected by welding, which has the advantages of compact structure and good sealing. Compared with other connection methods, butt welding connection has higher reliability and durability.

Classification of Stainless Steel Butt Weld Fittings

There are various types of stainless steel butt weld fittings that can meet the design requirements of various pipeline systems. The common types of butt weld fittings include stainless steel butt weld elbow, tee, concentric reducer, eccentric reducer, cross, cap, stub end, etc. These fittings play important roles in different pipeline systems.

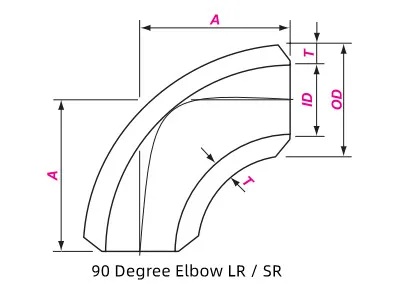

Stainless Steel Butt Weld Elbow

Stainless steel butt weld elbow is the most common type of pipe fittings in stainless steel butt weld fittings. Butt weld elbow can be divided into long radius elbow and short radius elbows according to different bending radius. According to the angle, it can be divided into 45 degree elbow, 90 degree elbow, and 180 degree elbows.

Specification of ASME B16.9 Elbow

Stainless steel butt weld elbow produced according to the ASME B16.9 standard. This standard have a wide range of sizes, from 1/2 “to 48”. The common wall thickness pressure levels include Sch 5s, Sch 10s, Sch 10, Sch 20, Sch 30, Sch 40s, STD, Sch 40, Sch 60, Sch 80s, XS, etc. Among them, the most commonly used are STD and XS. It depends on the design requirements and working pressure of the pipeline.

| Size Range | 1/2″ – 48″ / DN15 – 1200 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

Dimension of 90 Degree Elbow

| Nominal size | Outside Diameter at Bevel | Center to End | ||

| 90 Degree Elbows | ||||

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | – |

| 20 | 3/4 | 26.7 | 38 | – |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1-1/4 | 42.2 | 48 | 32 |

| 40 | 1-1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2-1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3-1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 400 | 16 | 406.4 | 610 | 406 |

| 450 | 18 | 457.0 | 686 | 457 |

| 500 | 20 | 508.0 | 762 | 508 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1448 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

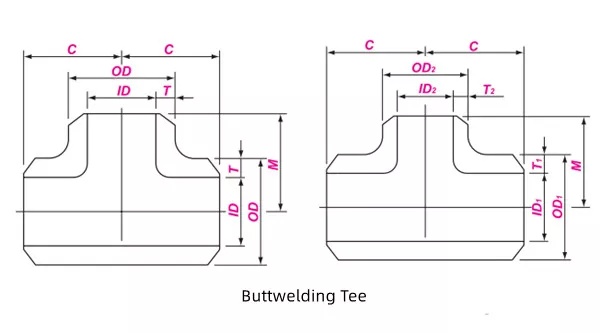

Stainless Steel Butt Weld Tee

Stainless steel butt weld tee is a common type of pipeline connection accessory, consisting of three ends. The horizontal two ends are the main pipe ends, and the vertical one is the branch pipe end. It is mainly used to connect pipelines, control fluid flow, and achieve operations such as opening, closing, splitting, and mixing of fluids. According to the diameter between the ends, butt weld tee can be divided into equal tee and reducing tee.

Specification of Butt Weld Tee

| Shape Type | Equal Tee and Reducing Tee |

| Size Range | 1/2″ – 48″ / DN15 – 1200 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

Dimension

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD1×OD2 | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 11/4 | 42.2 | 48 | 48 |

| 40 | 11/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 21/2 | 73.0 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 90 | 31/2 | 101.6 | 95 | 95 |

| 100 | 4 | 114.3 | 105 | 105 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273.0 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457.0 | 343 | 343 |

| 500 | 20 | 508.0 | 381 | 381 |

| 550 | 22 | 559.0 | 419 | 419 |

| 600 | 24 | 610.0 | 432 | 432 |

| 650 | 26 | 660.0 | 495 | 495 |

| 700 | 28 | 711.0 | 521 | 521 |

| 750 | 30 | 762.0 | 559 | 559 |

| 800 | 32 | 813.0 | 597 | 597 |

| 850 | 34 | 864.0 | 635 | 635 |

| 900 | 36 | 914.0 | 673 | 673 |

| 950 | 38 | 965.0 | 711 | 711 |

| 1000 | 40 | 1016.0 | 749 | 749 |

| 1050 | 42 | 1067.0 | 762 | 711 |

| 1100 | 44 | 1118.0 | 813 | 762 |

| 1150 | 46 | 1168.0 | 851 | 800 |

| 1200 | 48 | 1219.0 | 889 | 838 |

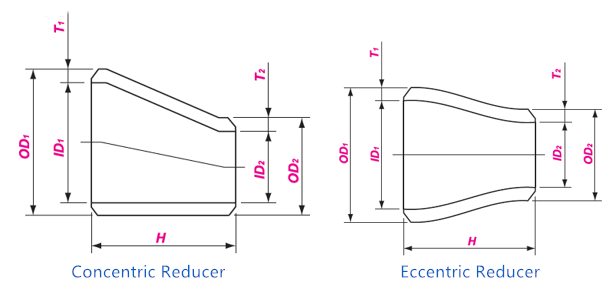

Stainless Steel Butt Weld Reducer

Stainless steel butt weld reducers are a special type of stainless steel butt weld fittings mainly used to connect two pipes of different diameters. According to different structures, it can be divided into stainless steel concentric reducers and eccentric reducers.

Specification

Stainless steel reducer belong to stainless steel butt weld fittings, produced in accordance with the American standard ASME B16.9. Their size characteristics are reflected in their wide range of specifications, diverse wall thickness sizes, wide application areas, and high degree of customization. These characteristics make it an indispensable and important component in pipeline systems.

| Size Range | 3/4″ – 60″ / DN20 – 1500 |

| Thickness Schedule | SCH 10 – SCH 80, SCH 160, XXS |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

Dimension of ASME B16.9 Reducer

| OD1 | OD2 | END TO END |

| NPS | NPS | H |

| 3/4 | 3/8 – 1/2 | 38 |

| 1 | 1/2 – 3/4 | 51 |

| 1-1/4 | 1/2 – 1 | 51 |

| 1-1/2 | 1/2 – 1 1/4 | 64 |

| 2 | 3/4 – 1 1/2 | 76 |

| 2-1/2 | 1 – 2 | 89 |

| 3 | 1 1/4 – 2 1/2 | 102 |

| 4 | 2 – 3 1/2 | 102 |

| 5 | 2 – 4 | 127 |

| 6 | 2 1/2 – 5 | 140 |

| 8 | 3 1/2 – 6 | 152 |

| 10 | 4 – 8 | 178 |

| 12 | 5 – 10 | 203 |

| 14 | 6 – 12 | 330 |

| 16 | 6 – 14 | 356 |

| 18 | 8 – 16 | 381 |

| 20 | 10 – 18 | 508 |

| 22 | 12 – 20 | 508 |

| 24 | 12 – 22 | 508 |

| 26 | 12 – 24 | 610 |

| 28 | 14 – 26 | 610 |

| 30 | 14 – 28 | 610 |

| 32 | 20 – 30 | 610 |

| 34 | 22 – 32 | 610 |

| 36 | 22 – 34 | 610 |

| 38 | 24 – 36 | 610 |

| 40 | 28 – 38 | 610 |

| 42 | 28 – 40 | 610 |

| 44 | 32 – 42 | 610 |

| 46 | 34 – 44 | 711 |

| 48 | 36 – 46 | 711 |

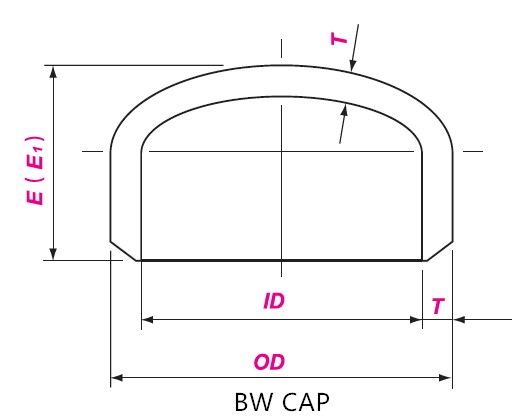

Stainless Steel Butt Weld Cap

Stainless steel butt weld cap is made of stainless steel material and fixed at the end of the pipeline by welding, used to seal the pipeline. It’s function is the same as a pipe plug, also known as stainless steel plug or stainless steel head. As an important pipeline connection accessory, it plays a crucial role in multiple fields.

Specification of Stainless Steel Butt Weld Cap

| Size | 1/2″– 48″ / DN15 – 1200 |

| Thickness | SCH 10 – SCH 160, XXS |

| Dimensions | ANSI / ASME B16.9 / MSS SP 43/JIS B2311/2312/2313/DIN2605/2615/2616/EN10253 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Dimension of ASME B16.9 Stainless Steel Butt Weld Cap

| DN | NPS | OD | E | E1 |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1-1/4 | 42.2 | 38 | 38 |

| 40 | 1-1/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 2-1/2 | 73.0 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 3-1/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273.0 | 127 | 152 |

| 300 | 12 | 323.8 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457.0 | 203 | 229 |

| 500 | 20 | 508.0 | 229 | 254 |

| 550 | 22 | 559.0 | 254 | 254 |

| 600 | 24 | 610.0 | 267 | 305 |

| 650 | 26 | 660.0 | 267 | — |

| 700 | 28 | 711.0 | 267 | — |

| 750 | 30 | 762.0 | 267 | — |

| 800 | 32 | 813.0 | 267 | — |

| 850 | 34 | 864.0 | 267 | — |

| 900 | 36 | 914.0 | 267 | — |

| 950 | 38 | 965.0 | 305 | — |

| 1000 | 40 | 1016.0 | 305 | — |

| 1050 | 42 | 1067.0 | 305 | — |

| 1100 | 44 | 1118.0 | 343 | — |

| 1150 | 46 | 1168.0 | 343 | — |

| 1200 | 48 | 1219.0 | 343 | — |

Material Features of Stainless Steel Butt Weld Fittings

The main material of stainless steel butt weld fittings is stainless steel, which is a metal material with excellent corrosion resistance, high strength, and high temperature performance. There are various types of stainless steel, such as ASTM A403 WP 304/L, 316/L, etc. The selection of these materials depends on the specific application environment and requirements.

ASTM A403 specification is a standard for austenitic stainless steel materials, which includes various grades such as 304, 316, 316L, etc. The ASTM A403 specification specifies the manufacturing, inspection, and testing requirements for stainless steel butt welded pipe fittings. Classify and name fittings based on their material type, size, and pressure rating to indicate their applicable range. In addition, the specifications also specify requirements for the chemical composition, mechanical properties, heat treatment, surface treatment, and other aspects of different grades of stainless steel.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | |||

| ASTM A403 WP904L | MIN | 23.00 | 19.00 | 4.00 | 1.00 | ||||||

| MAX | 0.02 | 2.00 | 0.045 | 0.035 | 1.00 | 28.00 | 23.00 | 5.00 | 0.10 | 2.00 | |

| ASTM A403 WP31254 | MIN | 17.50 | 19.50 | 6.00 | 0.18 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 0.25 | 1.0 | |

| ASTM A403 WP321 | MIN | 9.00 | 17.00 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 12.00 | 19.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 | ASTM A403 WP904L | ASTM A403 WP31254 | ASTM A403 WP321 |

| T.S (MPA) | 515 min | 515 min | 490 min | 650-820 | 515 min |

| Y.S (MPA) | 205 min | 205 min | 220 min | 300 min | 205 min |

| EL % | 28 min | 28 min | 28 min | 28 min | 28 min |

Process of Stainless Steel Butt Weld Fittings

In ASTM A403 specification, the manufacturing process of welded pipe fittings includes steps such as raw material preparation, cutting and processing, forging, welding, heat treatment, surface treatment, etc. During the manufacturing process, attention should be paid to preventing material damage, oxidation, and decarburization to ensure the surface quality and performance of the product.

The heat treatment of stainless steel pipe fittings mainly includes three processes: heating, insulation, and cooling. These processes are interconnected and uninterrupted. The ASTM A403 standard specifies the time, temperature, and cooling method for solution annealing corresponding to different grades of stainless steel materials.

Advantage

Reliable Connection

Convenient construction

Economic superiority

Strong durability

Application

Stainless steel butt weld fittings are widely used in multiple fields due to their excellent corrosion resistance and high strength.

Petrochemical Industry

Nuclear Power

Mechanical

Medical Equipment