What is Carbon Steel Butt Weld Tee

Carbon steel butt weld tee has a 90 degree branch and a straight line pipe that will provide a connection to install another device for the pipeline systems.

We made carbon steel butt weld tee by wrought materials in both seamless and welded construction. Welding the tee fittings to the pipe causes it to be leak-proof, adds strength, utilizes a small amount of space and minimizes the possibility of erosion and corrosion

Carbon Steel Butt weld Tees conform to ASTM A234.

Both straight and reducing Carbon Steel Butt weld Tees are stocked.

Supply Range

Standard: ASME B16.9 ; EN10253-2

Size: 1/2″, 1″, 2″, 3″, 4″, 6″, 8″, 10″, 12″, 16″, 20″, 24″ to 80″

Schedule: Sch 20, STD, Sch 40, XS, Sch 80, Sch 100, Sch 120, Sch 140, Sch 160, XXS

End: Plain (PE) or Bevel (BE)

Surface: Blasting and Painting, PE Coating, Hot Dip Galvanized.

ASME B16.9 Tee of Various Sizes and Shapes

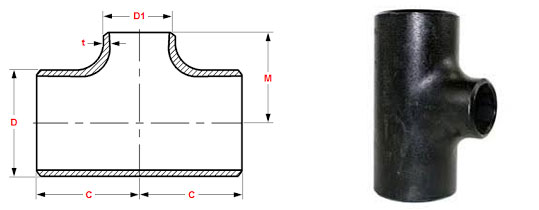

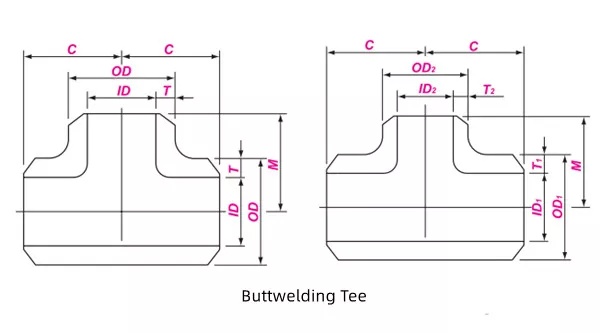

ASME B16.9 carbon steel butt weld tee with three outlets in same or different size and named as equal tee and reducing tee. The connecting ends are in same sizes, called equal tee, while branch size is smaller than run pipe size, we call it as reducing tee. Butt welding tee is widely used in petroleum, chemical industry, power plant and other industrial pipelines. The common used material are carbon steel A234 WPB.

Features of Equal Tee

Equal Tee (or straight tee), means the branch diameter of this tee is same with the main pipe (Run pipe) diameter of this tee.

There are three ends in a ‘T’ formed pipe tee.

Equal tees which have the same size openings.

Equal tee make them open of various size and two openings of the same size.

An equal tee utilises pressure fittings on two or more finishes.

An equal tee has a strong opening. This opening is utilised as a part of conjunction with a strong fitting for a get out an opening on a drain pipe.

Features of Reducing Tee

Reducing Tee is a T-shaped pipe fitting with two outlets that cut at 90 degrees to the main line. These tees are available with a combination of diverse outlet sizes.

Reducing tee make them open of various size and two openings of the same size.

A reducing tee has dragged to attach the fitting to a divider or stud.

A reducing tee utilises pressure fittings on two or more finishes.

A reducing tee has a strong opening. This opening is utilised as a part of conjunction with a strong fitting for a get out an opening on a drain pipe.

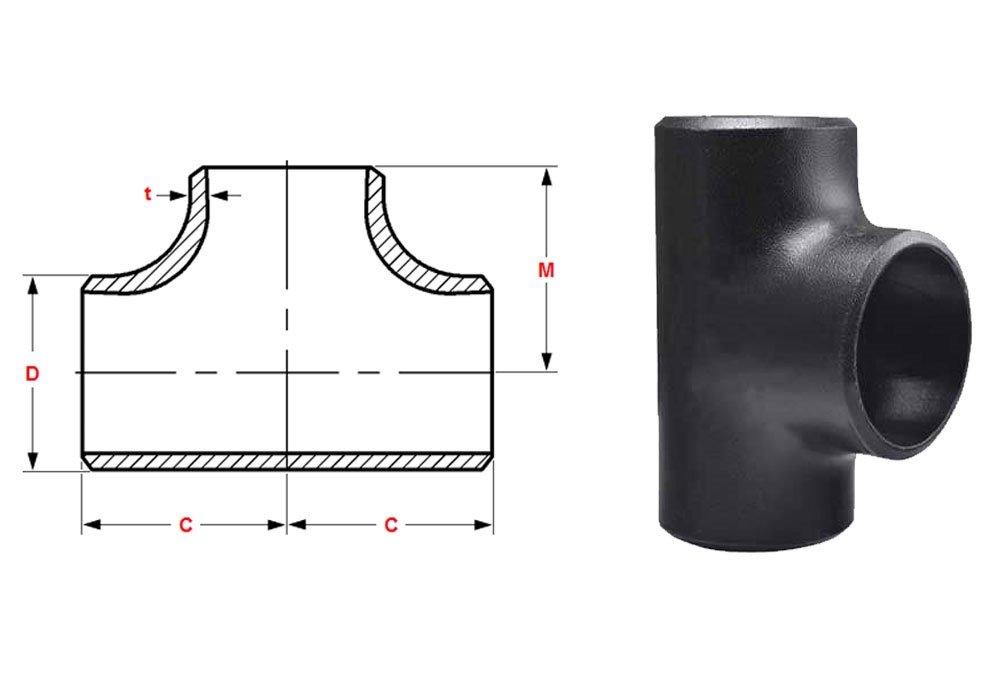

Dimension of Carbon Steel Butt Weld Tee

| Size | Outside Diameter (mm) | Center to End | ||

| DN | NPS | OD | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1-1/4 | 42.2 | 48 | 48 |

| 40 | 1-1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2-1/2 | 73 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 90 | 3-1/2 | 101.6 | 95 | 95 |

| 100 | 4 | 114.3 | 105 | 105 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457 | 343 | 343 |

| 500 | 20 | 508 | 381 | 381 |

| 550 | 22 | 559 | 419 | 419 |

| 600 | 24 | 610 | 432 | 432 |

| 650 | 26 | 660 | 495 | 495 |

| 700 | 28 | 711 | 521 | 521 |

| 750 | 30 | 762 | 559 | 559 |

| 800 | 32 | 813 | 597 | 597 |

| 850 | 34 | 864 | 635 | 635 |

| 900 | 36 | 914 | 673 | 673 |

| 950 | 38 | 965 | 711 | 711 |

| 1000 | 40 | 1016 | 749 | 749 |

| 1050 | 42 | 1067 | 762 | 711 |

| 1100 | 44 | 1118 | 813 | 762 |

| 1150 | 46 | 1168 | 851 | 800 |

| 1200 | 48 | 1219 | 889 | 838 |

| 1300 | 52 | 1321 | 965 | 914 |

| 1400 | 56 | 1422 | 1041 | 965 |

| 1600 | 64 | 1626 | 1194 | 1092 |

| 1700 | 68 | 1727 | 1270 | 1168 |

| 1800 | 72 | 1829 | 1320 | 1245 |

| 1900 | 76 | 1930 | 1422 | 1320 |

| 2000 | 80 | 2032 | 1499 | 1397 |

1) Besides the above mentioned standards, the standards of GB/T 10752 SH 3408 SH 3409 HG/T 21635 HG/T 21631 SY/T 0510 DL/T 695 EN 10253 etc.are also applied.

2) For the straight tees with DN≥650(NPS 26)and the reducing tees with DN≥350(NPS 14 , the outlet sizes are recommended to use (that mean the other sizes may be applied).

3) For the tees and crosses with the sizes larger than that listed in the above table,they will be supplied subject to the sized agreed by purchaser and manufacturer or according to manufacturer’s size.

ASME B16.9 Carbon Steel Butt Weld Tee Weight List

| Size | WEIGHT (KG) | ||||||||||||

| DN | NPS | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 15 | 1/2 | – | 0.15 | 0.16 | 0.16 | – | 0.2 | 0.2 | – | – | – | 0.25 | 0.35 |

| 20 | 3/4 | – | 0.18 | 0.2 | 0.2 | – | 0.3 | 0.3 | – | – | – | 0.35 | 0.45 |

| 25 | 1 | – | 0.27 | 0.28 | 0.28 | – | 0.45 | 0.45 | – | – | – | 0.54 | 0.77 |

| 32 | 1-1/4 | – | 0.46 | 0.55 | 0.55 | – | 0.7 | 0.7 | – | – | – | 0.91 | 1.26 |

| 40 | 1-1/2 | – | 0.68 | 0.78 | 0.78 | – | 1.25 | 1.25 | – | – | – | 1.39 | 1.83 |

| 50 | 2 | – | 0.96 | 1.17 | 1.17 | – | 1.61 | 1.61 | – | – | – | 2.39 | 2.89 |

| 65 | 2-1/2 | – | 2.06 | 2.21 | 2.21 | – | 2.92 | 2.92 | – | – | – | 3.81 | 5.21 |

| 80 | 3 | – | 2.87 | 3.23 | 3.23 | – | 4.42 | 4.42 | – | – | – | 6.17 | 8.01 |

| 90 | 3-1/2 | – | 3.65 | 4.33 | 4.33 | – | 5.95 | 5.95 | – | – | – | – | – |

| 100 | 4 | – | 4.56 | 5.68 | 5.68 | – | 7.88 | 7.88 | – | 10 | – | 11.8 | 14.5 |

| 125 | 5 | – | – | 9.08 | 9.08 | – | 12.9 | 12.9 | – | 16.8 | – | 20.5 | 24 |

| 150 | 6 | – | – | 13.6 | 13.6 | – | 20.5 | 20.5 | – | 26.1 | – | 32.5 | 38.1 |

| 200 | 8 | 17.5 | 22 | 25.5 | 25.5 | 31.8 | 38.7 | 38.7 | 45.4 | 54.1 | 60.4 | 66.6 | 64.6 |

| 250 | 10 | 28 | 37.1 | 44.8 | 44.8 | 59.2 | 59.2 | 69.7 | 83.3 | 96.6 | 113 | 125 | 113 |

| 300 | 12 | 42.6 | 55.7 | 63.1 | 68.1 | 93 | 83.2 | 112 | 137 | 160 | 178 | 204 | 160 |

| 350 | 14 | 64.5 | 76.3 | 76.3 | 88.7 | 119 | 101 | 148 | 183 | 211 | 238 | 264 | – |

| 400 | 16 | 78.2 | 95.7 | 95.7 | 126 | 164 | 126 | 191 | 252 | 294 | 342 | 375 | – |

| 450 | 18 | 102 | 141 | 121 | 179 | 237 | 160 | 269 | 357 | 419 | 471 | 529 | – |

| 500 | 20 | 168 | 198 | 150 | 235 | 317 | 190 | 365 | 489 | 566 | 651 | 724 | – |

| 550 | 22 | 185 | 241 | 182 | – | 414 | 241 | 482 | 636 | 743 | 846 | 947 | – |

| 600 | 24 | 222 | 305 | 205 | 340 | 516 | 272 | 589 | 796 | 930 | 1046 | 1174 | – |

| 650 | 26 | 340 | – | 254 | – | – | 337 | – | – | – | – | – | – |

| 700 | 28 | 390 | 478 | 289 | – | – | 383 | – | – | – | – | – | – |

| 750 | 30 | 420 | 549 | 332 | – | – | 441 | – | – | – | – | – | – |

| 800 | 32 | 480 | 627 | 379 | 631 | – | 503 | – | – | – | – | – | – |

| 850 | 34 | 540 | 709 | 429 | 714 | – | 569 | – | – | – | – | – | – |

| 900 | 36 | 610 | 796 | 481 | 872 | – | 639 | – | – | – | – | – | – |

| 950 | 38 | – | – | 537 | – | – | 713 | – | – | – | – | – | – |

| 1000 | 40 | – | – | 598 | – | – | 791 | – | – | – | – | – | – |

| 1050 | 42 | – | – | 636 | – | – | 846 | – | – | – | – | – | – |

| 1100 | 44 | – | – | 712 | – | – | 946 | – | – | – | – | – | – |

| 1150 | 46 | – | – | 779 | – | – | 995 | – | – | – | – | – | – |

| 1200 | 48 | – | – | 850 | – | – | 1080 | – | – | – | – | – | – |

| 1300 | 52 | – | – | 917 | – | – | – | – | – | – | – | – | – |

| 1400 | 56 | – | – | 1065 | – | – | – | – | – | – | – | – | – |

| 1500 | 60 | – | – | 1226 | – | – | – | – | – | – | – | – | – |

| 1600 | 64 | – | – | 1398 | – | – | – | – | – | – | – | – | – |

| 1700 | 68 | – | – | 1580 | – | – | – | – | – | – | – | – | – |

| 1800 | 72 | – | – | 1740 | – | – | – | – | – | – | – | – | – |

| 1900 | 76 | – | – | 1980 | – | – | – | – | – | – | – | – | – |

| 2000 | 80 | – | – | 2290 | – | – | – | – | – | – | – | – | |

Carbon Steel Butt Weld Tee Grades Material

ASTM A420 WPL6

A860 WPHY42

ASTM A860 WPHY 52

ASTM A860 WPHY 60

ASTM A860 WPHY 65

The Advantages of Butt Weld Fittings

Durable

Leak proof

Increase connection strength

Reduce corrosion and wear

A welded system use space as economically as possible