Steel Pipe Coupling are used to connect two pipes or tubes together by screwed ( threaded) or socket welding. It comes in many shapes and sizes.

How many Types of Steel Pipe Coupling?

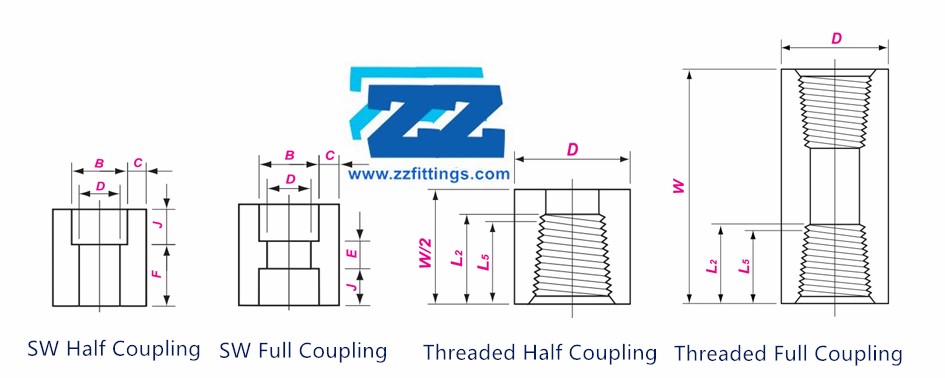

Based on the connection method, there are threaded coupling and socket weld coupling.

According to the shape, we can divide steel pipe coupling into straight and reducing coupling.

Based on the length, we can call them as full coupling and half coupling.

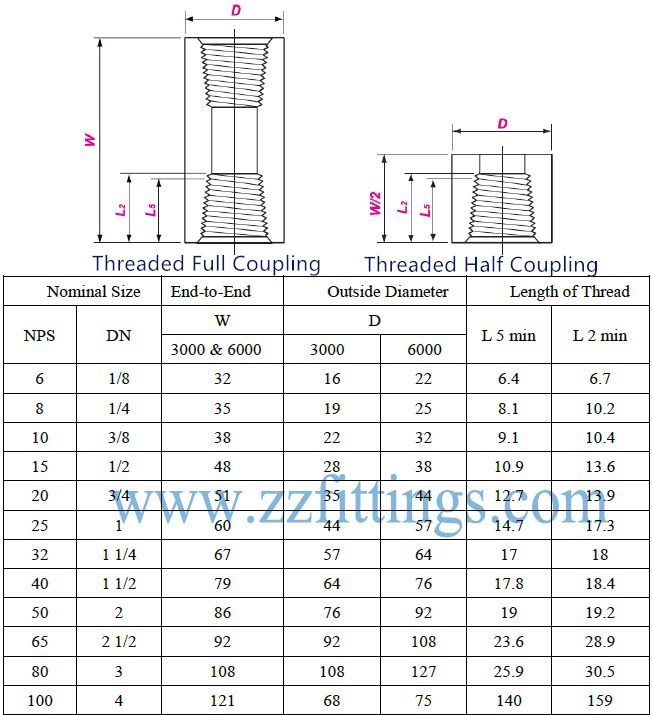

Threaded Coupling

We also named threaded pipe coupling as screwed coupling. They have thread at one or both ends that allows two steel pipes or tubes to be joined. The common thread types are NPT, BSPP and BSPT.

Supply Range

Size: 1/8″ to 4″

Pressure: 3000LB, 6000LB

Standard: ASME B16.11 & BS3799

Threaded Coupling Dimensions

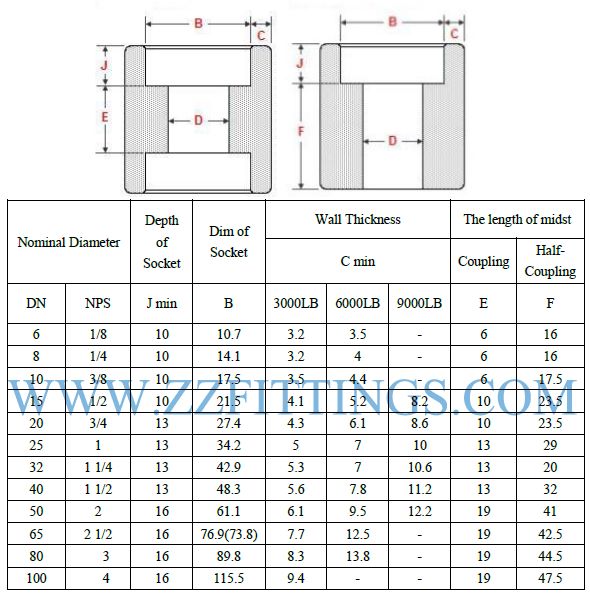

Socket Weld Coupling

Same as other socket weld fittings, they are generally used to connect steel pipe which nominal diameter below 4 inch. Socket weld pipe coupling also have full and half coupling.

Supply Range

Size: 1/8″ to 4″

Pressure: 3000, 6000, 9000 LB

Standard: ASME B16.11, BS3799, JIS B2316

Socket Weld Coupling Dimensions

Straight Pipe Coupling

The diameter of both ends are same, we call them straight pipe fittings. It includes straight coupling, tee, elbow and union.

Reducing Coupling

One end is large diameter, the other end is small diameter. We named them as reducing fittings, it is available in reducing pipe coupling, nipple, elbow, tee, concentric & eccentric reducer.

Full Coupling VS Half Coupling

Half coupling is only threaded or socket weld at one end, and the other end can be welded directly on the pipe. Full coupling has both ends of THD & SW.

From the name, we can see the length of half coupling is half of full length.

We supply full & half couplings in material of stainless steel, carbon steel, alloy steel, duplex steel, cooper nickel and nickel alloy.