On 8th, August, we received an inquiry from an American client who needed of a batch of stainless steel threaded union in SS304.

Union is one of our main products. We offered our quotation based on different quantity.

6 days later, we received PO from the client. Then we confirmed the PO with detailed information on email and talked with this client on the phone.

The goods is in stock and after 3 days of marking and packing, we arranged UPS delivery to US.

Product picture

Stainless Steel Threaded Union Specification

A Stainless Steel Threaded Union is a type of fitting used in piping systems to join two pipes or components that can be easily disconnected and reconnected without the need for welding or flanging. They are commonly used when frequent disassembly is required for maintenance, inspection, or repair. The union is designed with a male and female thread that allows for quick assembly and disassembly by simply screwing or unscrewing the parts.

| Standard: | ASME/ANSI B16.11, BS3799, MSS SP-83 |

| Diameter Range | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″,4” |

| Thread Type | PF, PT, NPT, BSPP and BSPT |

| Stainless Steel | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

Pressure and Temperature Ratings

Stainless steel threaded unions can handle a range of pressures, from low-pressure applications to high-pressure systems, depending on the size and design of the union.

They are typically rated to handle pressures from 150 psi to 2000 psi (depending on the specific type), and can withstand a range of temperatures, generally between -50°F to 1000°F (though this can vary depending on the specific grade of stainless steel used).

ASME B16.11 Threaded Union Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | ||

| ASTM A182 F304L | MIN | 8.00 | 18.00 | |||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | 0.10 | ||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

ASME B16.11 Threaded Union Mechnical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F304L | ASTM A182 F316 |

| T.S (MPA) | 515 min | 485 min | 515 min |

| Y.S (MPA) | 205 min | 170 min | 205 min |

| EL % | 30 min | 30 min | 30 min |

| R/A % | 50 min | 50 min | 50 min |

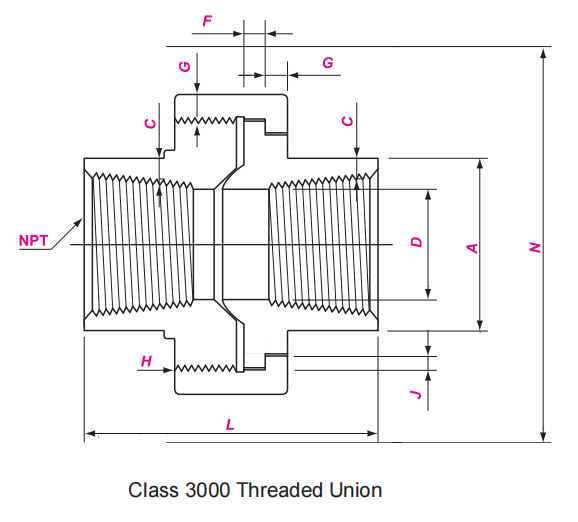

CLASS 3000 Threaded Union Dimensions

| Nominal Size | Pipe End | Wall | Bone | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem Nut | |

| DN | NPS | Amin | Cmin | D | Fmin | Gmin | H | Jmin | Lnom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 6.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 8 | 1/4 | 19.1 | 3.0 | 11.1 9.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 10 | 3/8 | 22.9 | 3.2 | 14.3 13.5 | 3.4 | 3.4 | 14 | 1.4 | 46.0 | 56 |

| 15 | 1/2 | 27.7 | 3.7 | 17.9 17.1 | 3.7 | 3.7 | 14 | 1.5 | 49.0 | 59 |

| 20 | 3/4 | 33.5 | 3.9 | 23.0 21.4 | 4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 25 | 1 | 41.4 | 4.5 | 29.0 27.7 | 4.6 | 4.4 | 11 | 1.9 | 62.0 | 79 |

| 32 | 11/4 | 50.5 | 4.9 | 37.7 35.4 | 5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 40 | 11/2 | 57.2 | 5.1 | 43.5 41.2 | 5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 50 | 2 | 70.1 | 5.5 | 55.6 52.1 | 6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 65 | 21/2 | 85.3 | 7.0 | 66.3 64.3 | 7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 80 | 3 | 102.4 | 7.6 | 82.6 77.3 | 8.3 | 8.0 | 8 | 3.5 | 109.0 | 176 |

ASME Threaded Union Weight in KG

| NOMINAL SZIE | WEIGHT | |

| DN | NPS | 3000 |

| 6 | 1/8 | 0.25 |

| 8 | 1/4 | 0.30 |

| 10 | 3/8 | 0.35 |

| 15 | 1/2 | 0.46 |

| 20 | 3/4 | 0.61 |

| 25 | 1 | 0.85 |

| 32 | 1-1/4 | 1.35 |

| 40 | 1-1/2 | 2.85 |

| 50 | 2 | 4.00 |

| 65 | 2-1/2 | 4.90 |

| 80 | 3 | 7.10 |

Threaded Union Applications

– Piping Systems

– HVAC

– Food and Beverage Industry

– Marine and Offshore

– Pharmaceutical and Chemical Processing

– Oil & Gas

Advantages

– Good Quality

– Fast Delivery

– Safe Package

– Abundant Stock

– Reasonable Price

– Reliable Shipment