ZIZI ENGEERING are manufacturers of stainless steel socket weld union. We can supply high quality MSS SP-83 Union offer you the best prices in the market. Stainless steel socket weld unions are designed for wide use in different industries.

Stainless Steel Socket Weld Union Material & Grades

We can supply stainless steel socket weld union for connecting pipes in many industrial processes that no leakage can be permitted. And limited by its manufacturer standard, MSS SP-83 more suitable for small diameters application below 3 inch.

| Size Range | 1/8″ – 3″ / DN6 – DN80 |

| Pressure Rating | Class 3000lbs |

| Standard | MSS SP-83 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

| Application | Oil and Gas /Pipeline/Power Industries/Chemical Industries |

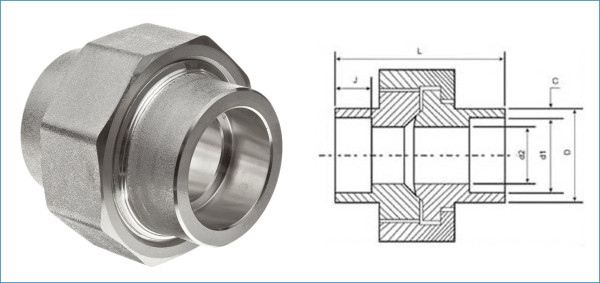

MSS SP-83 Socket Weld Union

MSS SP 83 is the specification for socket weld and threaded union which cover size tolerance, marking, material etc.

MSS SP-83 stainless steel socket weld union is an active pipe connection fitting with the feature of easy for assemble and disassemble. It can be widely used in different diameters pipeline connection, and the connection of meter and valve with pipe line.

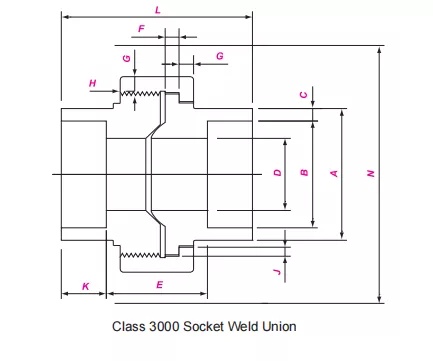

Dimension of Stainless Steel Socket Weld Union

| DN | NPS | A | B | C | D | E | F | G | H | J | K | L | N |

| 6 | 1/8 | 21.8 | 10.9 | 3.2 | 6.1 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 8 | 1/4 | 21.8 | 14.3 | 3.3 | 8.5 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 10 | 3/8 | 25.9 | 17.7 | 3.5 | 11.8 | 23.8 | 3.4 | 3.4 | 14 | 1.4 | 9.7 | 46 | 56 |

| 15 | 3/4 | 31.2 | 21.9 | 4.1 | 15 | 23.8 | 3.7 | 3.7 | 14 | 1.5 | 9.7 | 49 | 59 |

| 20 | 1/2 | 37.1 | 27.3 | 4.3 | 20.2 | 28.6 | 4.1 | 4.1 | 11 | 1.7 | 12.7 | 56.9 | 66 |

| 25 | 1 | 45.5 | 34 | 5 | 25.9 | 30.2 | 4.6 | 4.4 | 11 | 1.9 | 12.7 | 62 | 79 |

| 32 | 1-1/4 | 54.9 | 42.8 | 5.3 | 34.3 | 36.6 | 5.3 | 5.2 | 10 | 2.1 | 12.7 | 71.1 | 94 |

| 40 | 1-1/2 | 61.5 | 48.9 | 5.5 | 40.1 | 38.1 | 5.8 | 5.6 | 10 | 2.3 | 12.7 | 76.5 | 112 |

| 50 | 2 | 75.2 | 61.2 | 6 | 51.7 | 41.4 | 6.6 | 6.4 | 10 | 2.7 | 15.7 | 86.1 | 132 |

| 65 | 2-1/2 | 91.7 | 73.9 | 7.7 | 61.2 | 56.9 | 7.5 | 7.1 | 8 | 3.1 | 15.7 | 102.4 | 150 |

| 80 | 3 | 109.2 | 89.9 | 8.3 | 76.4 | 58.7 | 8.3 | 8 | 8 | 3.5 | 15.7 | 109 | 176 |

Weight List(KG)

| NOMINAL SZIE | WEIGHT | |

| DN | NPS | 3000 |

| 6 | 1/8 | 0.25 |

| 8 | 1/4 | 0.3 |

| 10 | 3/8 | 0.35 |

| 15 | 3/4 | 0.46 |

| 20 | 1/2 | 0.61 |

| 25 | 1 | 0.85 |

| 32 | 1-1/4 | 1.35 |

| 40 | 1-1/2 | 2.85 |

| 50 | 2 | 4 |

| 65 | 2-1/2 | 4.9 |

| 80 | 3 | 7.1 |

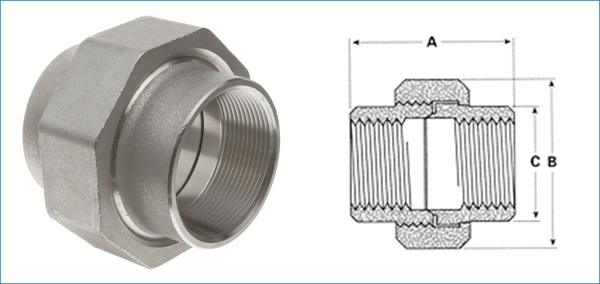

Socket Weld Union VS Threaded Union

Stainless steel socket weld union and threaded union are two different types of fittings. They have significant differences in structure, connection method, application scenarios.

Structural

Socket weld union: It is usually composed of sockets, sockets, socket slots, and other parts.

Threaded union: It refers to threaded pipe connectors, usually composed of nuts, cloud heads, flat joints, and other parts.

Connection method

Socket weld union: Socket welding is the process of inserting steel pipes into socket holes for welding, hence it is called a “socket joint”.

Threaded union: Threaded connection is the process of screwing steel pipes into screw holes for connection, hence it is called a “threaded flexible joint”.

Application scenarios

Socket weld union: Due to its structural characteristics and connection methods, plug-in joints are widely used in heavy machinery, large structures, and situations that require high leak prevention capabilities.

Threaded union: Threaded joints are more common in small mechanical equipment, pipeline connections, and situations that require frequent replacement or maintenance due to their convenient and fast connection characteristics.

ASTM A182 Socket Weld Union

ASTM A182 forged pipe fittings refer to pipe fittings forged from alloy, stainless steel, or duplex steel materials. These material typically have excellent corrosion resistance, good mechanical properties to ensure the safe, and operation of pipeline.

Chemical Composition of Stainless Steel Socket Weld Union

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min |

| EL % | 30 min | 30 min | 35 min | 35 min |

| R/A % | 50 min | 50 min | 50 min | 45 min |

Advantage of Stainless Steel Socket Weld Union

Stainless steel socket weld union, as a type of pipe made of malleable stainless steel, has various advantages.

Corrosion resistance

High strength

Easy installation and disassembly

Good sealing performance

Strong adaptability

Aesthetics

Economy