On April 7th, We received an inquiry for customer in Zambia. This inquiry is about stainless steel 316 socket weld tee. This regular customer from Zambia has purchased forged pipe fittings from our company multiple times. Our cooperation is perfect,so we are confident in winning this order. On April 13th, the customer place the order by email, we arrange production after received payments.

ASME B16.11 Stainless Steel 316 Socket Weld Tee

ASME B16.11 is the specification for forged pipe fittings,including socket weld and threaded type. Material including carbon steel, alloy steel and stainless steel. Also described as Class 2000, 3000, 6000 threaded end fittings. Class 3000, 6000, and 9000 for socket weld end fittings.

Stainless steel 316 socket weld tee is a high pressure pipe fitting in three ways which made by forging from round steel. They are in T-shaped and know as equal tee and reducing tee. It is generally applicable to pipes with nominal diameter less than NPS 2.

Socket Weld Fittings are a family of high pressure forging fittings that used only in conjunction with ANSI Pipe and are available in the same size range.

Even though there are some similarities between the shapes of the two welds, but socket weld is still considered to be different from a fillet weld.

| Shape | Straight and Reducing Fittings |

| Size Range | 1/8″- 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000LBS, 6000Lbs, 9000lbs. |

| Stainless Steel | ASTM A182 F304 / 304L / 304H, 316 / 316L, 321, 310S, 317, 347, 904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Class 6000 Socket Weld Tee: for matching with Sch 160 steel pipe.

Class 9000 Socket Weld Tee: for connecting with Sch XXS steel pipe

Feature of ASTM A182 F316 Material

The standard specification for A182 F316 Material covers both forged low alloy steel as well as stainless steel pipe parts, which are designed to be used in pressure systems. These parts can include stainless steel socket weld tee,elbow,coupling and other similar parts that meet the specified size or size standards.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

Mechanical Properties

| MATERIAL | ASTM A182 F316 |

| T.S (MPA) | 515 min |

| Y.S (MPA) | 205 min |

| EL % | 30 min |

| R/A % | 50 min |

Marking and Inspection of Stainless Steel 316 Socket Weld Tee

Package of Socket Weld Tee

Pack all stainless steel 316 socket weld tee in cartons.

Stick label on all cartons.

Put cartons into wooden box.

Make shipping mark on wooden box.

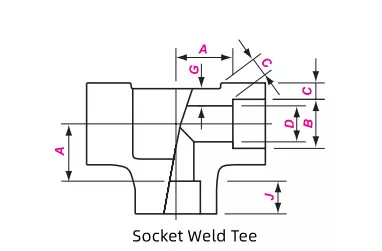

ASME B16.11 Socket Weld Tee Dimensions

| DN | NPS | B | C | A | G | |||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||

| 6 | 1/8 | 10.9 | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 11.0 | 11.0 | – | 2.41 | 3.15 | – |

| 8 | 1/4 | 14.3 | 3.78 | 3.30 | 4.60 | 4.01 | – | – | 11.0 | 13.5 | – | 3.02 | 3.68 | – |

| 10 | 3/8 | 17.7 | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 13.5 | 15.5 | – | 3.20 | 4.01 | – |

| 15 | 1/2 | 21.9 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 15.5 | 19 | 25.5 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 27.3 | 4.09 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 19 | 25.5 | 28.5 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 34.0 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 22.5 | 27.0 | 32.0 | 4.55 | 6.35 | 9.09 |

| 32 | 11/4 | 42.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 27.0 | 32.0 | 35.0 | 4.85 | 6.35 | 9.70 |

| 40 | 11/2 | 48.9 | 6.35 | 5.54 | 8.92 | 7.80 | 12.7 | 11.12 | 32.0 | 38.0 | 38.0 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 38.0 | 41.0 | 54.0 | 5.54 | 8.74 | 11.07 |

| 65 | 21/2 | 73.9 | 8.76 | 7.62 | – | – | – | – | 41.0 | – | – | 7.01 | – | – |

| 80 | 3 | 89.9 | 9.52 | 8.30 | – | – | – | – | 57.0 | – | – | 7.62 | – | – |

| 100 | 4 | 115.5 | 10.69 | 9.35 | – | – | – | – | 66.5 | – | – | 8.56 | – | – |

Stainless Steel 316 Socket Weld Tee Weight Chart in KG

| DN | NPS | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.13 | 0.22 | – |

| 8 | 1/4 | 0.14 | 0.25 | – |

| 10 | 3/8 | 0.16 | 0.45 | – |

| 15 | 1/2 | 0.35 | 0.55 | 1.15 |

| 20 | 3/4 | 0.48 | 0.90 | 1.80 |

| 25 | 1 | 0.66 | 1.46 | 2.25 |

| 32 | 1-1/4 | 1.00 | 1.90 | 3.95 |

| 40 | 1-1//2 | 1.40 | 2.80 | 4.87 |

| 50 | 2 | 2.00 | 3.70 | 8.89 |

| 65 | 2-1/2 | 4.10 | – | – |

| 80 | 3 | 5.55 | – | – |

| 100 | 4 | 15.6 | – | – |