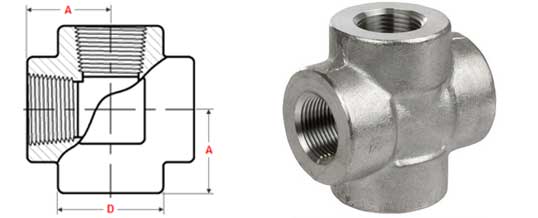

Stainless steel threaded cross is a commonly used high-pressure pipe fitting in industrial pipelines. They are mainly used to connect pipeline systems and change fluid direction. It is made of stainless steel material. Stainless steel has excellent corrosion resistance and durability.

Threaded cross adopts a threaded form to connect the pipeline, which has the features of easy installation and good sealing. Stainless steel threaded cross is widely used in pipeline systems in industries.

Scope of Stainless Steel Threaded Cross

Stainless steel threaded cross under ASME B16.11 standard. They are commonly used for connecting small-diameter high-pressure pipelines, with sizes ranging from 1/8 inch to 4 inches (DN6-DN100). The pressure levels include 2000LB, 3000LB, and 6000LB. These factors collectively determine the detailed dimensions and performance parameters of threaded cross.

| Shape | Equal and Reducing Cross Tee |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000 lbs, 3000 lbs, 6000 lbs |

| Standard | ASME B16.11, BS3799 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L, F321 |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

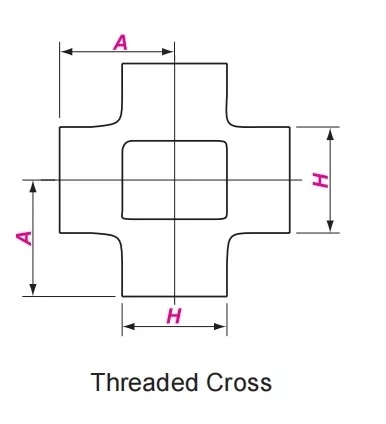

Dimension of ASME B16.11 Threaded Cross

| DN | NPS | A | H | ||||

| 2000LB | 3000LB | 6000LB | 2000LB | 3000LB | 6000LB | ||

| 6 | 1/8 | 21 | 21 | 25 | 22 | 22 | 25 |

| 8 | 1/4 | 21 | 25 | 28 | 22 | 25 | 33 |

| 10 | 3/8 | 25 | 28 | 33 | 25 | 33 | 38 |

| 15 | 1/2 | 28 | 33 | 38 | 33 | 38 | 46 |

| 20 | 3/4 | 33 | 38 | 44 | 38 | 46 | 56 |

| 25 | 1 | 38 | 44 | 51 | 56 | 62 | 75 |

| 32 | 1 1/4 | 44 | 51 | 60 | 56 | 62 | 75 |

| 40 | 1 1/2 | 51 | 60 | 64 | 62 | 75 | 84 |

| 50 | 2 | 60 | 64 | 83 | 75 | 84 | 102 |

| 65 | 2 1/2 | 76 | 83 | 95 | 92 | 102 | 121 |

| 80 | 3 | 86 | 95 | 106 | 109 | 121 | 146 |

| 100 | 4 | 106 | 114 | 114 | 146 | 152 | 152 |

Weight of Stainless Steel Threaded Cross

| DN | NPS | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.16 | 0.26 | 0.42 |

| 8 | 1/4 | 0.18 | 0.28 | 0.68 |

| 10 | 3/8 | 0.2 | 0.48 | 0.79 |

| 15 | 1/2 | 0.42 | 0.7 | 1.38 |

| 20 | 3/4 | 0.54 | 1.08 | 2.16 |

| 25 | 1 | 0.79 | 1.75 | 2.7 |

| 32 | 1-1/4 | 1.2 | 2.28 | 4.74 |

| 40 | 1-1/2 | 1.68 | 4.08 | 5.85 |

| 50 | 2 | 2.64 | 4.66 | 10.7 |

| 65 | 2-1/2 | 5.05 | 8.64 | 15.4 |

| 80 | 3 | 7.38 | 12.8 | 26.5 |

| 100 | 4 | 17.6 | 21.5 | 35.4 |

Advantage of Stainless Steel Threaded Cross

Strong corrosion resistance

Good wear resistance

Easy installation

Space saving

Features of ASTM A182 F316 Material

ASTM A182 F316 threaded cross is made of grade SS316 stainless steel material. ASTM A182 belongs to the American standard for high-temperature forged or rolled alloy steel and stainless steel flange steel. The implementation standard is ASTM A182/A182M-2018. Stainless steel 316 has a low carbon content and excellent corrosion resistance, especially under high temperature conditions, when the concentration of sulfuric acid is within a specific range, its performance is particularly outstanding.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316 | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | 0.01 |

Due to the excellent corrosion resistance. ASTM A182 F316 threaded cross can work stably for a long time in various corrosive media, extending the service life of pipeline systems.

Mechanical Properties

| MATERIAL | ASTM A182 F316 |

| T.S (MPA) | 515 min |

| Y.S (MPA) | 205 min |

| EL % | 30 min |

| R/A % | 50 min |

Stainless steel 316 has high compressive strength and good mechanical properties.

ASTM A182 F316 stainless steel threaded cross play an important role in pipeline systems. It has excellent material properties, flexible structural design, outstanding performance, and wide range of applications.

Inspection and Package