Stainless steel socket weld outlet is widely used in pipeline systems. This article will provide a detailed introduction to the specification of stainless steel socket weld outlet.

MSS SP-97 is the production standard for American forged steel outlet. According to this standard, various types of outlet can be designed and manufactured. Stainless steel outlet including butt welded outlet, threaded outlet, socket outlet etc.

Stainless steel socket weld outlet is a forged and reinforced type of pipe fitting, which is molded and forged from round steel or steel ingots and then processed by lathe machine. It is mainly suitable for high-pressure pipelines that can withstand high pressure, equipment with precise size requirements, and other high-pressure fields. It is forged from high-quality stainless steel and can withstand high pressure and temperature, with excellent corrosion resistance, oxidation resistance, and high temperature resistance.

Specification of MSS SP-97 Stainless Steel Socket Weld Outlet

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs |

| Standard | MSS SP-97 |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317 ,347, 904L, 321 |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

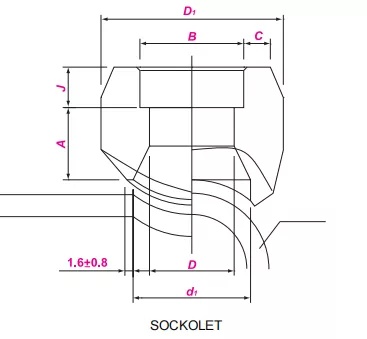

Dimension of Socket Weld Outlet

| DN | NPS | DN | NPS | J | A | D | C | d1 | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 9.5 | 10 | – | 27 | – | 3.18 | – | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 9.5 | 10 | – | 27 | – | 3.78 | – | 16 | – |

| 18~900 | 1/2~36 | 10 | 3/8 | 9.5 | 13 | – | 30 | – | 4.01 | – | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 9.5 | 16 | 24 | 38 | 47 | 4.67 | 5.97 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 12.5 | 16 | 25 | 47 | 53 | 4.90 | 6.96 | 30 | 25 |

| 32~900 | 1¼~36 | 25 | 1 | 12.5 | 22 | 29 | 56 | 63 | 5.69 | 7.92 | 36 | 33 |

| 40~900 | 1½~36 | 32 | 1¼ | 12.5 | 22 | 30 | 66 | 74 | 6.07 | 7.92 | 45 | 38 |

| 50~900 | 2 | 40 | 1½ | 12.5 | 24 | 32 | 75 | 83 | 6.35 | 8.92 | 51 | 49 |

| 65~900 | 2½~36 | 50 | 2 | 16 | 24 | 37 | 90 | 104 | 6.93 | 10.92 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2½ | 16 | 25 | – | 105 | – | 8.76 | – | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 16 | 30 | – | 124 | – | 9.52 | – | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 19 | 30 | – | 154 | – | 10.69 | – | 121 | – |

Weight List (KG)

| Nominla Size | SWOutlet | ||

| DN | NPS | 3000 | 6000 |

| 6 | 1/8 | 0.05 | |

| 8 | 1/4 | 0.05 | |

| 10 | 3/8 | 0.09 | |

| 15 | 1/2 | 0.16 | 0.35 |

| 20 | 3/4 | 0.2 | 0.47 |

| 25 | 1 | 0.42 | 0.68 |

| 32 | 1-1/4 | 0.59 | 1.1 |

| 40 | 1-1/2 | 0.7 | 1.3 |

| 50 | 2 | 1.1 | 2.45 |

| 65 | 2-1/2 | 1.4 | |

| 80 | 3 | 2.3 | |

| 90 | 3-1/2 | ||

| 100 | 4 | 4.20 | |

Advantage of Stainless Steel Socket Weld Outlet

Socket weld outlet have multiple advantages in pipeline systems, making them an indispensable pipeline connection accessory in many industrial fields.

Easy and fast installation

Good sealing performance

Wide applicability

Strong bearing capacity

Easy to maintain and replace

Good economy

Environmental protection and energy conservation

How to Inspect of Stainless Steel Outlet

ZIZI ENGEERING CO LTD specializes in producing stainless steel socket weld outlet in accordance with the American standard MSS SP-97. We can supplied specifications ranging from 1/8 “to 4” and pressures of Class 3000 and 6000. Every pipe fittings of our products undergoes strict quality inspection before leaving the factory to ensure that every product received by customers is qualified.

Visual the surface of socket weld fittings body.

Measure dimensions that large end diameter, small end diameter, wall thickness of outlets.

Check the marking of 2.5″-2″ x 1/4″ Class 3000 ASTM A182 F316 MSS SP-97 ZZ724