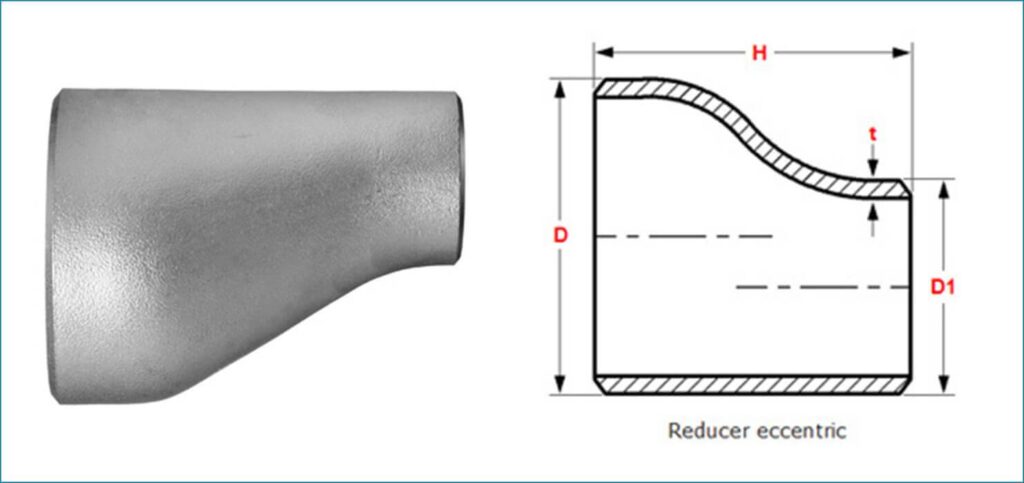

Stainless steel eccentric reducer refers to a reducer with a center that is not in the same straight line. It is mainly used to connect two pipes of different diameters and is a common pipe connection accessory.

Stainless steel eccentric reducer has advantages such as corrosion resistance, high temperature resistance, and high pressure resistance, making it suitable for various complex environments. It can achieve smooth transition of pipeline diameter, reduce fluid resistance, and improve fluid transportation efficiency. The correct use of stainless steel eccentric reducer can not only change the flow path, but also save materials, smooth pipelines, prevent blockages, and improve work efficiency.

Standard for Stainless Steel Eccentric Reducer

The manufacturing of stainless steel eccentric reducer needs to be carried out in accordance with relevant national standards. The current standards mainly include GB/T 12459, GB/T 13041, SH 3408, ASME B16.9, etc. Among them, ASME B16.9 is the American standard for the production of welded pipe fittings, which mainly specifies the detailed dimensions, specifications, and tolerance ranges of various welded pipe fittings.

ASME B16.9 is a standard specification for factory manufactured seamless and welded elbows, tees, and reducers . ASME B16.9 standard is published by the American Society of Mechanical Engineers (ASME) and is primarily used to specify the size, shape, tolerances, and quality requirements for factory prefabricated elbows, tees, and reducers used in metal piping systems with diameters ranging from 1/2 inch to 48 inch.

| Size Range | 3/4″ – 60″ / DN20 – 1500 |

| Thickness Schedule | SCH 10 – SCH 80, SCH 160, XXS |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

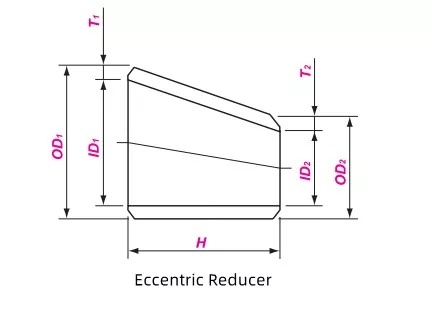

Dimension of ASME B16.9 Eccentric Reducer

ASME B16.9 standard specifies the detailed dimensions and specifications of eccentric reducers, including the diameter, wall thickness, length, and other parameters of their major and minor ends.

| OD1 | OD2 | END TO END |

| NPS | NPS | H |

| 3/4 | 3/8 – 1/2 | 38 |

| 1 | 1/2 – 3/4 | 51 |

| 1 1/4 | 1/2 – 1 | 51 |

| 1 1/2 | 1/2 – 1 1/4 | 64 |

| 2 | 3/4 – 1 1/2 | 76 |

| 2 1/2 | 1 – 2 | 89 |

| 3 | 1 1/4 – 2 1/2 | 102 |

| 4 | 2 – 3 1/2 | 102 |

| 5 | 2 – 4 | 127 |

| 6 | 2 1/2 – 5 | 140 |

| 8 | 3 1/2 – 6 | 152 |

| 10 | 4 – 8 | 178 |

| 12 | 5 – 10 | 203 |

| 14 | 6 – 12 | 330 |

| 16 | 6 – 14 | 356 |

| 18 | 8 – 16 | 381 |

| 20 | 10 – 18 | 508 |

| 22 | 12 – 20 | 508 |

| 24 | 12 – 22 | 508 |

| 26 | 12 – 24 | 610 |

| 28 | 14 – 26 | 610 |

| 30 | 14 – 28 | 610 |

| 32 | 20 – 30 | 610 |

| 34 | 22 – 32 | 610 |

| 36 | 22 – 34 | 610 |

| 38 | 24 – 36 | 610 |

| 40 | 28 – 38 | 610 |

| 42 | 28 – 40 | 610 |

| 44 | 32 – 42 | 610 |

| 46 | 34 – 44 | 711 |

| 48 | 36 – 46 | 711 |

Tolerance

ASME B16.9 standard also specifies the tolerance range for stainless steel eccentric reducers to ensure accuracy in size and shape. The tolerance range covers multiple aspects such as length, wall thickness, inner diameter, and outer diameter, and manufacturers must ensure that the eccentric reducer produced is within these tolerance ranges.

| TOLERANCES FOR BW REDUCER | ||||

| DN | NPS | OD | ID | H,F |

| 15-65 | 1/2-2-1/2 | +1.6 -0.8 | ±0.8 | ±2 |

| 80-90 | 3-3-1/2 | ±1.6 | ±1.6 | ±2 |

| 100 | 4 | ± 1 6 | ±1.6 | ±2 |

| 125-200 | 5-8 | +24 -1.6 | ±1.6 | ±2 |

| 250-450 | 10-18 | +4.0 -3.2 | ±3.2 | ±2 |

| 500-600 | 20-24 | +6.4 -4.8 | ±4.8 | ±2 |

| 650-750 | 26-30 | +6.4 -4.8 | ±4.8 | ±5 |

| 800-1200 | 32-48 | +6.4 -4.8 | ±4.8 | ±5 |

ASTM A403 Eccentric Reducer

The stainless steel eccentric reducer is made of high-quality stainless steel material, which has excellent corrosion resistance, mechanical properties, and processing performance, and can meet the requirements of various complex environments. ASTM A403 is a standard developed by the American Society for Testing and Materials (ASTM), specifically designed, manufactured, and inspected for forged or cast austenitic stainless steel and ferritic stainless steel fittings used in pressure applications. Common stainless steel grades include 304, 316, 316L, etc.

All stainless steel fittings produced according to the ASTM A403 standard must undergo a series of strict tests before leaving the factory, including but not limited to: chemical composition analysis: ensuring compliance with the specified chemical composition range. Mechanical performance testing: including tensile testing, hardness testing, impact testing, etc., to verify whether the strength, toughness, and plasticity of the product meet the standard requirements.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 28 min | 28 min |

ASTM A403 standard ensures the reliability and durability of stainless steel eccentric reducer under various harsh working conditions by strictly regulating the design, manufacturing, and inspection processes of stainless steel fittings.

The production standards for stainless steel eccentric reducer cover multiple aspects such as materials, manufacturing, connection, inspection, and packaging transportation. During production and use, operations and testing should be strictly carried out in accordance with relevant standards to ensure their quality and safety.

How to Calculate the Weight of Eccentric Reducer

Formula for calculating the weight of stainless steel eccentric reducer

0.02466 × t ×[ (D+D1)/2-S] × H / 1000

t: Wall thickness

D:Outside diameter of the larger end

D1:Outside diameter of the small end

H: End to end dimension

Weight List

| Large End Normal Size | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS | |

| DN | NPS | ||||||||||||

| 20 25 32 | 3/4 1 1-1/4 | 0.06 0.12 0.16 | 0.07 0.14 0.19 | 0.07 0.14 0.19 | 0.09 0.18 0.25 | 0.09 0.18 0.25 | 0.12 0.24 0.32 | 0.15 0.31 0.45 | |||||

| 40 50 65 | 1-1/2 2 2-1/2 | 0.25 0.37 0.79 | 0.29 0.46 0.85 | 0.29 0.46 0.85 | 0.38 0.63 1.12 | 0.38 0.63 1.12 | 0.51 0.93 1.46 | 0.70 1.20 2.00 | |||||

| 80 90 100 | 3 3-1/2 4 | 0.97 1.28 1.45 | 1.11 1.52 1.81 | 1.11 1.52 1.81 | 1.50 2.09 2.51 | 1.50 2.09 2.51 | 3.18 | 2.09 3.76 | 2.71 4.60 | ||||

| 125 150 200 | 5 6 8 | 5.57 | 6.16 | 3.04 4.35 7.12 | 3.04 4.35 7.12 | 8.88 | 4.33 6.55 10.8 | 4.33 6.55 10.8 | 12.7 | 5.63 8.35 15.1 | 16.9 | 6.86 10.4 18.6 | 8.02 12.2 18.0 |

| 250 300 350 | 10 12 14 | 8.18 11.1 24.6 | 9.99 14.6 29.5 | 11.8 16.5 29.6 | 11.8 17.8 34.3 | 16.0 24.3 46.0 | 16.0 21.8 39.0 | 18.8 29.5 57.4 | 22.5 35.7 70.8 | 26.0 41.7 81.5 | 30.4 46.5 92.0 | 33.7 53.3 102 | 30.4 41.7 |

| 400 450 500 | 16 18 20 | 30.5 36.8 65.5 | 36.5 51.3 86.7 | 36.6 44.1 65.5 | 48.3 65.3 102 | 62.7 86.2 138 | 48.3 58.3 86.7 | 79.7 107 174 | 96.2 130 213 | 112 152 247 | 130 171 284 | 143 193 316 | |

| 550 600 650 | 22 24 26 | 72.2 78.9 136 | 95.6 117 | 72.2 78.9 103 | 143 | 164 199 | 95.6 105 136 | 209 247 | 252 306 | 294 358 | 336 402 | 376 452 | |

| 700 750 800 | 28 30 32 | 147 157 168 | 183 196 209 | 111 119 127 | 230 | 147 158 168 | |||||||

| 850 900 950 | 34 36 38 | 179 189 | 223 236 | 135 143 151 | 245 282 | 179 190 200 | |||||||

| 1000 1050 1100 | 40 42 44 | 159 167 175 | 211 222 232 | ||||||||||

| 1150 1200 1300 | 46 48 52 | 213 222 241 | 283 296 | ||||||||||

| 1400 1500 | 56 60 | 259 278 | |||||||||||

Advantages and Scope of Application

Variety Material

Wide Application

High safety

Durable

Convenient installation

Good cost performance

Butt welding fittings are a very important component in pipeline fittings. They can connect pipelines, change the flow direction of pipelines, reduce fluid resistance, regulate flow rate, etc. Therefore, they are widely used in industries such as chemical, food, petroleum, natural gas, etc.