On January 6, 2025, we received an inquiry from a customer about SMO 254 concentric reducer. This customer is a high-quality old customer of our company and has placed orders with us many times, including flanges, pipe fittings, steel pipes and other products. According to customer feedback, our products are suitable, of good quality and thoughtful service, so the customer placed an order with us after getting the price that day.

ZIZI is a company specializing in the production and processing of pipes and accessories. The company is located in Shanghai, China’s international economic, financial, trade and shipping center. The pipes and pipe fittings we produce are mainly used in chemical, petroleum, natural gas, water conservancy, electric power, marine engineering and other fields. The products mainly include seamless pipes, welded pipes, butt-welded pipe fittings, high-pressure forged pipe fittings and flanges of various sizes.

What is an SMO 254 Concentric Reducer?

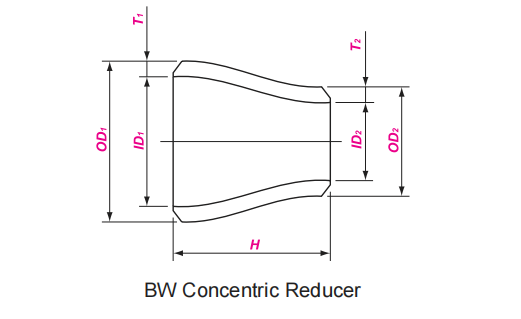

An SMO 254 Concentric Reducer is a type of buttweld pipe fitting designed to connect two pipes of different diameters in a coaxial (center-aligned) manner. It is commonly used in highly corrosive environments such as offshore, chemical, and marine industries due to its excellent corrosion resistance and high mechanical strength.

SMO 254 Material Key Features:

Excellent corrosion resistance in seawater, acids, and chlorides.

Higher strength than standard stainless steels (304, 316L).

Good weldability & formability.

Specification of A403 UNS S31254 Concentric Reducer

| Specifications | ASTM A403 / ASME SA403 |

| Size | Seamless Butt Weld Fittings : 1/2″ – 10″ |

| Welded Butt Weld Fittings : 1/2″ – 48″ | |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc |

Chemical Composition of SMO 254 Pipe Fittings

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | Cu |

| SMO 254(UNS S31254) | MIN | 17.50 | 19.50 | 6.00 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 |

Mechanical Properties of SMO 254 Material

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| SMO 254(UNS S31254) | 650 min | 300 min | 35 min | 50 min |

Equivalent UNS S31254 Butt weld Fittings

| STANDARD | AFNOR | WERKSTOFF NR. | UNS | SIS | EN |

| SMO 254 | Z1 CNDU 20.18.06Az | 1.4547 | S31254 | 2378 | X1CrNiMoCuN20-18-7 |

ASME B16.9 Concentric Reducer Dimensions

| OD1 | OD2 | END TO END | SCH 40 WEIGHT |

| NPS | NPS | H | KG |

| 3/4 | 3/8 – 1/2 | 38 | 0.07 |

| 1 | 1/2 – 3/4 | 51 | 0.14 |

| 1 1/4 | 1/2 – 1 | 51 | 0.19 |

| 1 1/2 | 1/2 – 1 1/4 | 64 | 0.29 |

| 2 | 3/4 – 1 1/2 | 76 | 0.46 |

| 2 1/2 | 1 – 2 | 89 | 0.85 |

| 3 | 1 1/4 – 2 1/2 | 102 | 1.11 |

| 4 | 2 – 3 1/2 | 102 | 1.8 |

| 5 | 2 – 4 | 127 | 3.05 |

| 6 | 2 1/2 – 5 | 140 | 4.35 |

| 8 | 3 1/2 – 6 | 152 | 7.12 |

| 10 | 4 – 8 | 178 | 11.8 |

| 12 | 5 – 10 | 203 | 17.8 |

| 14 | 6 – 12 | 330 | 34.3 |

| 16 | 6 – 14 | 356 | 48.3 |

| 18 | 8 – 16 | 381 | 65.3 |

| 20 | 10 – 18 | 508 | 102 |

| 22 | 12 – 20 | 508 | – |

| 24 | 12 – 22 | 508 | 143 |

| 26 | 12 – 24 | 610 | – |

| 28 | 14 – 26 | 610 | – |

| 30 | 14 – 28 | 610 | – |

| 32 | 20 – 30 | 610 | 230 |

| 34 | 22 – 32 | 610 | 245 |

| 36 | 22 – 34 | 610 | 282 |

How to inspect SMO254 concentric reducer?

Visual & Dimensional Inspection

✅ Visual Inspection:

Check for surface defects, cracks, dents, welding defects, and oxidation.

Ensure smooth and clean surface finish (pickled & passivated).

Verify correct marking (heat number, size, schedule, standard).

✅ Dimensional Inspection:

Measure diameter, wall thickness, and overall height according to ASME B16.9 / MSS-SP-43.

Check concentricity (ensure alignment of inlet and outlet).

Verify ovalization and end tolerances.

Applications of SMO 254 Concentric Reducers

✅ Desalination plants (resistant to seawater corrosion)

✅ Petrochemical & offshore industries

✅ Chemical processing (acidic environments, sulfuric acid resistance)

✅ Power plants (high-temperature and pressure applications)

✅ Pulp & paper industry (chloride-rich processes)

SMO 254 Concentric Reducers Advantages

Excellent corrosion resistance

– Strong resistance to pitting and crevice corrosion

– Resistant to corrosion by various chemical media

Good mechanical properties

– High strength and toughness

– Good machinability

Good hygienic properties

– High surface finish