What Is SMO 254 Flange

SMO 254 flange is a corrosion-resistant and high-temperature stainless steel flange forged from super austenitic stainless steel SMO 254 as the raw material. SMO 254 flange is a high-performance pipeline connector, especially suitable for scenarios that require working in harsh corrosive environments and high temperatures. Its excellent corrosion resistance and high-temperature performance make it widely used in industries such as marine engineering, chemical processing, petroleum, and natural gas.

SMO 254, also known as 6Mo stainless steel, contains approximately 6% molybdenum, which gives it excellent corrosion resistance, especially in chloride ion environments. This material can resist various corrosive media, such as chloride, sulfuric acid, acetic acid, and phosphoric acid. SMO 254 can maintain its mechanical properties and corrosion resistance at temperatures as high as 1000 ℉ (538 ℃). Despite its superior corrosion resistance, SMO 254 also maintains good strength and toughness.

ASTM A182 F44 Flange Material Characteristics

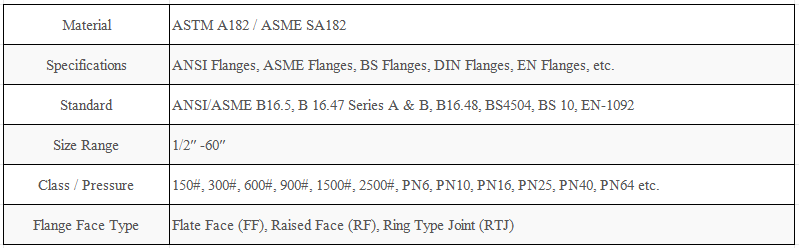

The American standard material for SMO 254 flange is ASTM A182 F44. ASTM A182 is a standard specification for forged or rolled alloy steel pipe flanges, forged fittings, valves, and parts. F44 refers to the material grade, which is equivalent to SMO 254 stainless steel material.

Chemical Composition

| C | Mn | P | S | Si | Ni | Cr | Mo | Cu | |

| MIN | 17.50 | 19.50 | 6.00 | 0.50 | |||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % |

| SMO 254 | 650 min | 300 min | 35 min | 50 min |

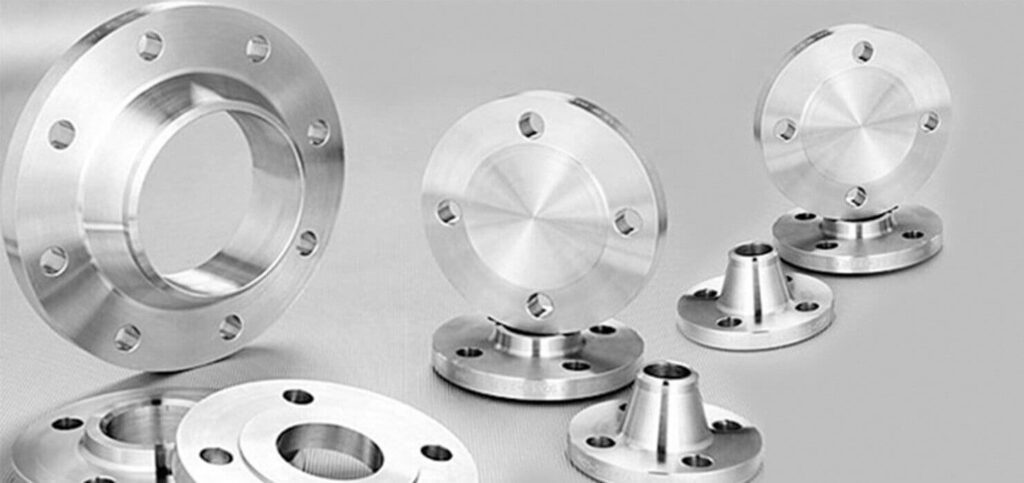

Types Of Forged Flange

Types of SMO 254 flanges:Slip on flange, weld neck flange, socket flange, threaded flange, lap joint flange, and blind flange.

Slip on flange: It is suitable for situations with low pressure and non-toxic media. It is easy to install, but has relatively poor sealing performance.

Weld neck flange: SMO 254 weld neck flange needs to be used in conjunction with bolts and gaskets. It has good sealing performance and is suitable for pipelines with significant pressure or temperature fluctuations.

Socket flange: Socket flange refers to a flange that inserts one end of the pipeline into the flange socket interface and connects the pipeline by welding at the pipe end and outer side. It is suitable for high pressure and harsh media situations, and has good sealing performance.

Lap joint flange: Lap joint flange is composed of flange plate, sealing ring, fasteners, etc. It has good sealing performance and is easy to install.

Thread flange: Thread flange is a non welded flange that processes the inner hole of the flange into a pipe thread and connects it with a threaded pipe.

Blind flange: Blind flange is a flange without a hole in the middle, used for sealing the end of pipelines.

SMO 254 Flange Application

Oil and Gas Industries

Food Processing Industries

Power Industries

Ship Building Industries

Paper Industries

Cement Industries

Chemical Industries