- Home

- Blog Custom Layout

- Butt Weld Fittings

- WPHY 60 Pipe Fittings

WPHY 60 Pipe Fittings

USD0.3-3200 USD0.2-3100

ASTM A860 WPHY 60 Pipe Fittings 1/2" to 80" Sch 20, STD, 40, XS, 80, 120, 160

- General Details

- Technical Info

- Related Products

High Yield Carbon Steel Fittings

ASTM A860 WPHY 42 / 46/ 52 / 56 / 60 / 65 / 70 is the material grade for High Yield Carbon Steel Buttweld Pipe Fittings and widely used with API 5L pipe. We stock ASTM A860 Equal & Reducing Tee, 90 Degree Elbow, Bends, Eccentric & Concentric Reducer and End Cap in commonly used sizes.

A860 Carbon Steel Fittings are known for their high strength and good corrosion resistance, high grade material WPHY 60 is more durable and cost-effective. It is appropriate to apply them in the high-pressure gas and oil transportation systems.

A860 WPHY 60 Pipe Fittings Available

A860 WPHY 60 Pipe Fittings Available

Equal Tee and Reducing Tee

90 Degree Elbow, 45 Degree Elbow, Long Radius Elbow, Short Radius Elbow.

Concentric Reducer and Eccentric Reducer

End Cap, Seamless Cap and Welded Cap

Type A Stub End, Type B Stub End, Type C Stub End.

Carbon Steel Buttweld Fittings Dimensions

Standard: ASME B 16.9

Size Range: 3/4″ to 48″ / DN20 to DN1200

Thickness: Sch 10, 20, STD, 40, 80, 100,120, 140,160, XXS

Form: Seamless or Welded

Surface: Black Primer, Galvanized and PE Coated.

Material Grades of ASME B16.9 Fittings

Carbon Steel : ASTM A234 WPB, A420 WPL3, WPL6, WPL9, WPHY42, 52, 60, 65, 70.

Stainless Steel BW: ASTM A403 WP304/304L, WP316/316L, WP321, WP317, WP310

Duplex Steel: ASTM A815 UNS S31803, S32205, S32550, S32750, S32760

Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

ASTM A860 Fittings

Package

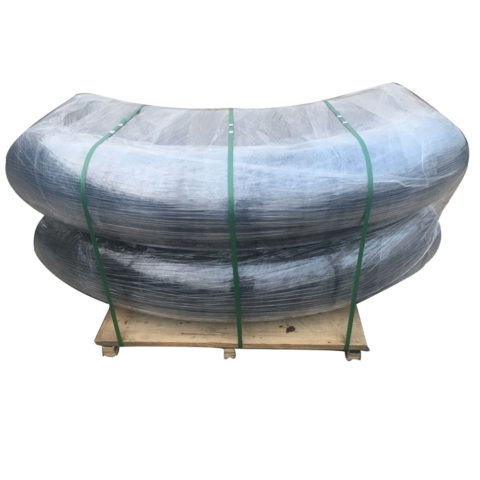

We marked all ASME B16.9 Buttweld Fittings with Grade, Lot No, Size, Standard and Thickness. All A860 Carbon Steel Fittings will be blasting and painting before shipment. We also use plastic bag to protect those fittings while shipping. Our workers packed ASTM A860 WPHY 60 Pipe Fittings into wooden pallets or cases.

ASTM A860 Fittings Package

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation.

Inspection

- Visual the surface of buttweld fittings body. Such as dents, die marks, porosity, undercuts etc.

- Check the marking. Such as size, material code, material grade, thickness, heat no.

- Measure dimensions. Such as outside diameter, height from end to end, wall thickness.

Advantages

- Good Quality

- Fast Delivery

- Safe Package

- Abundant Stock

- Reasonable Price

- Reliable Shipment

A860 WPHY 60 Properties

ASTM A860 WPHY 60 have high tensile strength and resistant to general corrosion, WPHY stands for Wrought Pipe High-Yield. WPHY 60 Pipe Fittings is high strength, reliability and accuracy in dimensions.

Chemical Composition,%

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.2 | 1-1.5 | 0.01 | 0.03 | 0.15-0.4 | 0.5 | 0.3 | 0.25 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 – 690 (Mpa) | 415 (Mpa) | 28 (%) |

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18