- Home

- Blog Custom Layout

- Forged Steel Olets

- Sockolet Class 3000

Sockolet Class 3000

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Sockolets Manufacturers

Zizi is an ISO certified and experienced manufacturer of Forged Sockolet in Class 3000, 6000 and 9000. The dimension is specified in MSS SP 97. There are another two types that weldolets and threadolets.

As a professional supplier and exporter, we are well aware of the requirements and have extensive production experience. Our factory is located in an industrial city Yanshan China which have mature technology and complete industrial chain.

Sockolet Fitting Dimensions

Standard: MSS-SP-97

Run Pipes Diameter Range: DN8– 900 / NPS1/4 – 36

Branch Diameter Range: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Rate: Class 3000, Class 6000, Class 9000

Surface: Anti-rust Oil and Galvanized

Material Grades of Socket Weld Olet

Duplex Steel Forged Outlet

ASTM A182 F51, F53, F55, F56, F60, S 31803, S 32205, S 32550, S 32750, S 32760

Stainless Steel Olet

ASTM A182 F304/304L/304H, F316/316L, F310, F317, F321, F347, F947

Alloy Steel Sockolet

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Carbon Steel SW Outlet

ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70

Branch Connection Fittings

Package of Forged Steel Sockolets

We marked all alloy steel sockolets with Grade, Lot No, Size, Standard and Pressure. All Sockolet Class 3000 is surfaced with oil before delivery. The workers sleeved forged steel sockolets into plastic bag individually, packed them in carton and wooden cases, then bundled packages with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

Inspection of Class 3000 Socket Weld Fittings

Visual the surface of socket weld fittings body.

Measure dimensions that large end diameter, small end diameter, wall thickness of outlets.

Check the marking of 4″ x 1″Class 3000 ASTM A182 F5 MSS SP-97 Z188

A182 F5 MATERIAL PROPERTIES

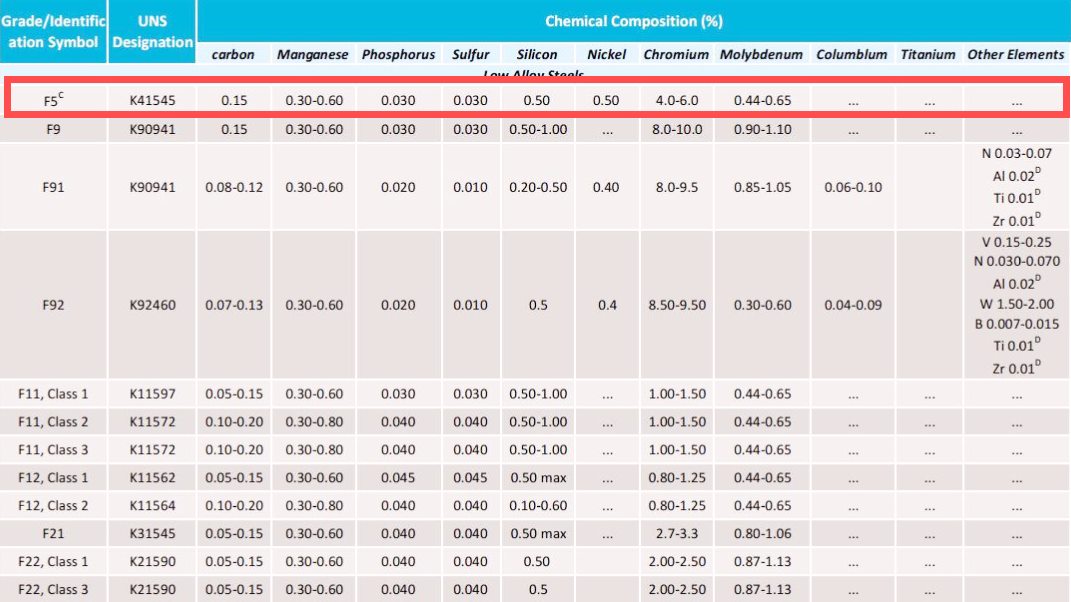

Chemical Composition

A182 F5 Material Chemical Composition

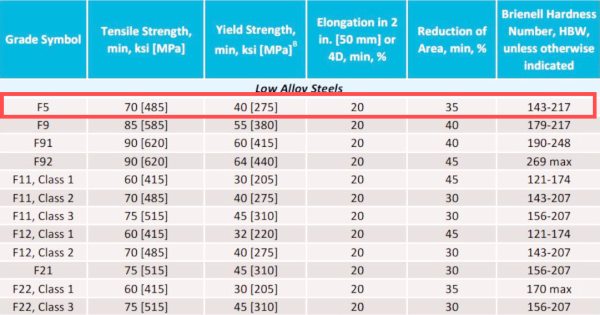

Mechanical Properties

A182 F5 Material Mechanical Properties

ASTM A182 Gr F5 Equivalent

| Forging | UNS | Casting Equivalent | DIN | DIN W. No | Application |

|---|---|---|---|---|---|

| A182 F5 | K41545 | A217-C5 | 12CRMO195 | 1.7362 | High Temp Refinery Service |

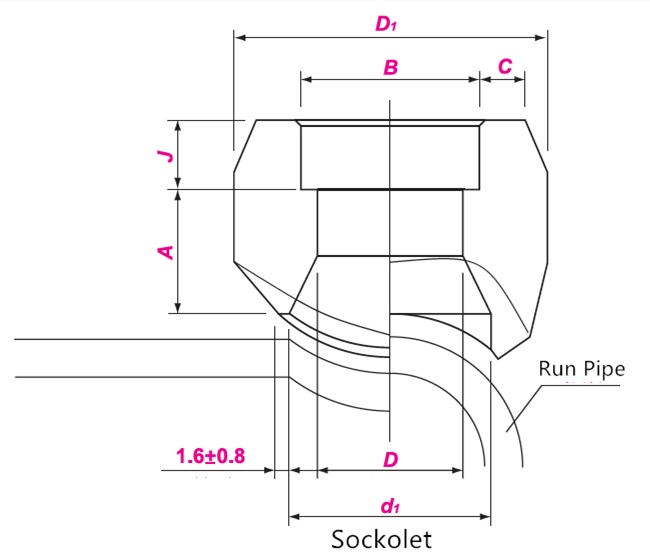

Socket Weld Outlet Drawing & Specification

Sockolet Drawing

| Nominal Size | Branch Nominal Size | Depth of Socket | Face of Fitting to Crotch | OD of Fitting | Socket Wall Thickness | Cut Hole Dia. | ||||||

| DN | NPS | DN | NPS | J min | A max | D 1 min | C min | d 1 nom | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 9.5 | 10 | – | 27 | – | 3.18 | – | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 9.5 | 10 | – | 27 | – | 3.78 | – | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 9.5 | 13 | – | 30 | – | 4.01 | – | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 9.5 | 16 | 24 | 38 | 47 | 4.67 | 5.97 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 12.5 | 16 | 25 | 47 | 53 | 4.9 | 6.96 | 30 | 25 |

| 32~900 | 1 1/4~36 | 25 | 1 | 12.5 | 22 | 29 | 56 | 63 | 5.69 | 7.92 | 36 | 33 |

| 40~900 | 1 1/2~36 | 32 | 1 1/4 | 12.5 | 22 | 30 | 66 | 74 | 6.07 | 7.92 | 45 | 38 |

| 50~900 | 2~36 | 40 | 1 1/2 | 12.5 | 24 | 32 | 75 | 83 | 6.35 | 8.92 | 51 | 49 |

| 65~900 | 2 1/2~36 | 50 | 2 | 16 | 24 | 37 | 90 | 104 | 6.93 | 10.92 | 65 | 59 |

| 80~900 | 3~36 | 65 | 2 1/2 | 16 | 25 | – | 105 | – | 8.76 | – | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 16 | 30 | – | 124 | – | 9.52 | – | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 19 | 30 | – | 154 | – | 10.69 | – | 121 | – |

Socket Weld 45 Degree Elbow

2" Socket Weld 45 Degree Elbow Class 3000 ASTM A182 F304 ASME B16.11

USD16 USD15

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18

A815 UNS S31803 Elbow Fittings

12" ELBOW 90 DEGREE LR SMLS ASME B16.9 ASTM A815 UNS S31803 SCH60

USD1516 USD1488