- Home

- Blog Custom Layout

- Socket Weld Reducing Tee

Socket Weld Reducing Tee

USD21 USD20

1 x 1 x 1/2 Socket Weld Reducing Tee Class 6000 ASTM A182 F316 ASME B16.11

- General Details

- Technical Info

- Documents

- Related Products

Leading manufacturer and exporter Zizi always supplies best quality Class 6000 Socket Weld Reducing Tee Fittings with attractive price and fast delivery. Reducing pipe fittings are covering tee, elbow, nipple, reducer, swage and coupling.

High pressure socket weld fittings are made of high strength, corrosion resistant stainless steel, so that withstand more pressure and temperature. What are they? Scoket weld Full and Half Couplings, 90 and 45 Degree Elbows, Equal Tees and Reducing Tees, Unions, Caps and Cross.

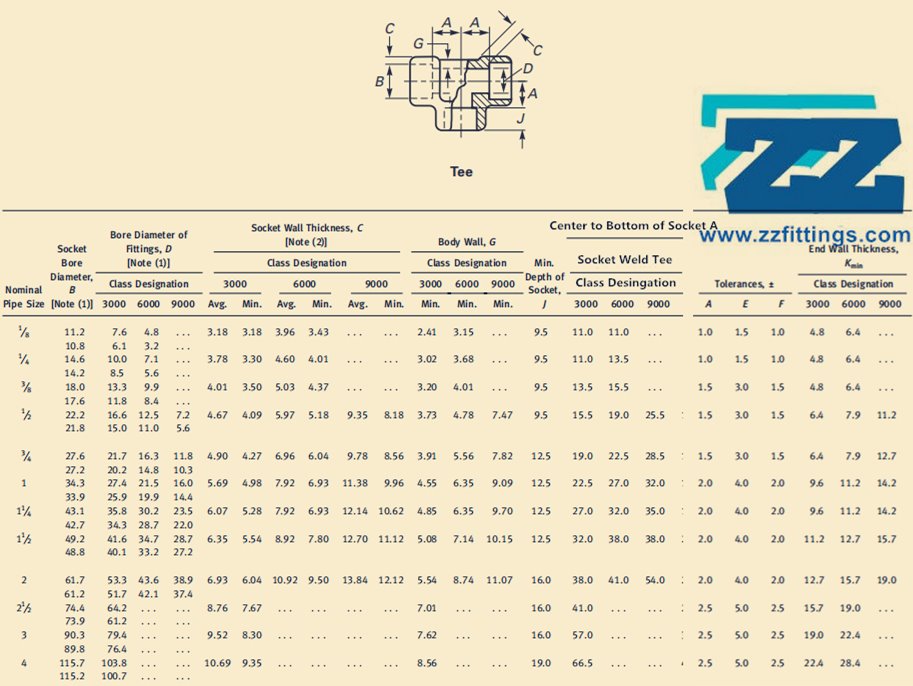

ASME Socket Weld Reducing Tee Dimensions

Socket Weld Reducing Tee Dimensions

Standard: ASME/ANSI B16.11, BS3799

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 3000 LB, 6000 LB, 9000 LB

Surface : Anti-rust Oil or Galvanized

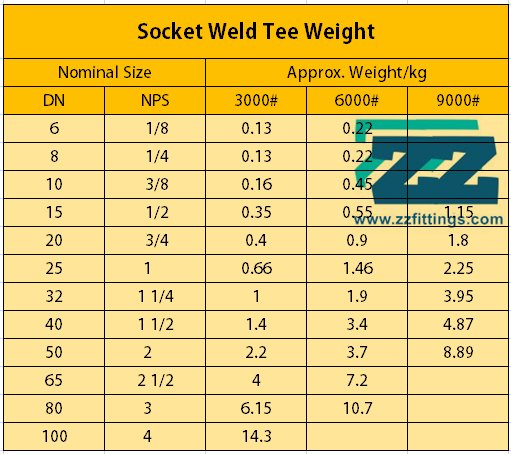

ASME B16.11 Socket Weld Tee Weight

The weights shall be designated as pressure classes 2000, 3000 and 6000 for threaded end fittings and class 3000, 6000 and 9000 for socket-weld end fittings.

Socket Weld Tee Weight

Material Grades of Reducing Tee Pipe Fitting

Stainless Steel Fittings: ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321

Carbon Steel: ASTM A105, A350 LF2, LF3, A694 F52, F60, F65, F70

Alloy Steel: ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel: ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S 32760

SS 316 Socket Weld Fitting

Package

We marked all Stainless Steel Socket Weld Fittings with Grade, Lot No, Size, Standard and Pressure. Our workers sleeved SS 316 Reducing Tees into plastic bag individually, wrapped with water-proof material, and put them into wooden case, finally bundled packages with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation

How to Identify the Size of Tee and Cross?

In the case of reducing tees and crosses, the size of the largest run opening shall be given first, followed by the size of the opening at the opposite end of the run. For tee, the size of the branch is given last. For cross, the largest side-outlet is the third dimension given, followed by the opening opposite.

Inspection

- Visual the surface of Socket Weld Tees body.

- Check the marking. “1 x 1/2 SW 6000 A182 F316 ASME B16.11 Z168”

- Measure the dimensions. Such as outside diameter, wall thickness, height.

- Test the properties stainless steel reducing tee.

Industries & Applications

Our Socket Weld Tee is used in various applications and industries as following:

- Sugar Industry

- Oil & Gas Industries

- Petrochemical Industries

- Power Plants Industry

- Fertilizers Industries

- Chemical Industries

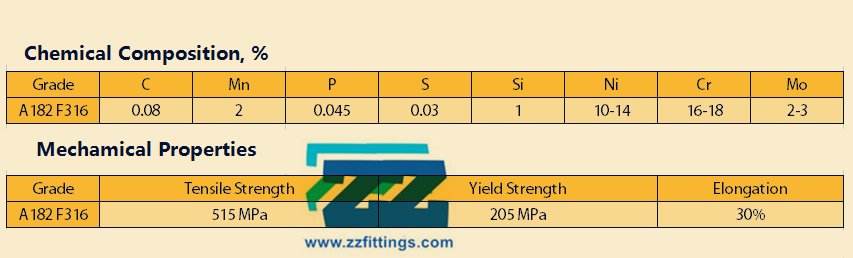

ASTM A182 F316 SPECIFICATION

ASTM A182 F316 SPECIFICATION

Threaded Half Coupling

2” Class 6000 Threaded Half Coupling BSPP ASTM A182 F22 ASME B16.11

USD56 USD55

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

Stainless Steel Eccentric Reducer

4"×3" Sch40S Stainless Steel Eccentric Reducer ASTM A403 WP304 ASME B16.9

USD15 USD13

Threaded Hex Head Bushing

Threaded Hex Head Bushing 3/8″×1/4″ BSPT ASTM A105 ASME B16.11

USD0.7 USD0.6