- Home

- Blog Custom Layout

- Duplex Steel Pipe Fittings

- Duplex Steel Buttweld Fittings

Duplex Steel Buttweld Fittings

USD300 USD295

Stub End Short Pattern 12" Sch40 Super Duplex SS2507 UNS S32750

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Duplex steel buttweld fittings have better resistance to sea water than stainless steel grade 316 pipe fittings, and so as the mechanical properties.

We offer a complete range of butt weld elbow, tee, reducer, bend, cap, cross and stub end, which are available in various size, specification, thickness and shapes for meeting customer’s requirements.

Duplex Steel are known by it’s highly corrosion resistance properties with respect to the standard austenitic grades or high alloyed ferrite.

What is the Duplex Steel Grades?

ASTM A815 UNS S31803 Buttweld Fittings

People described 31803 as a duplex stainless steel with a microstructure of 50:50 austenite and ferrite. The steel combines good mechanical strength (typically up to over 480 MPa yield strength) and ductility with moderate to good corrosion resistance in a variety of environments.

ASTM A815 UNS S32205 Buttweld Fittings

2205 is a duplex stainless steel, with a chemical composition of nearly equal proportions of austenite and ferrite. This combination allows the alloy to be stronger and tougher than standard austenitic steels.

Type of Duplex Steel Buttweld Fittings

| Duplex Steel 90 Degree Elbow | Duplex Steel 45 Degree Elbow |

| ASTM A815 Concentric Reducer | Duplex Steel Eccentric Reducer |

| A815 Duplex Steel Equal Tee | Duplex Steel Reducing Tee |

| Duplex 5D Bend | UNS S31803 3D Bend |

| Duplex Steel Long Stub End | UNS S32205 Short Stub End |

| Duplex Steel Cross | 2205 Duplex Steel Cap |

Duplex Steel Buttweld Fittings

Specification for Duplex Steel Pipe Fittings

Standard: ANSI/ASME B16.9, B16.28, MSS-SP-43

Specification: ASTM / ASME A815 / SA815

Size: NPS 1/2″ to 48″

Thickness: Sch 10S to Sch XXS

Type: Seamless & Welded Buttweld Fittings

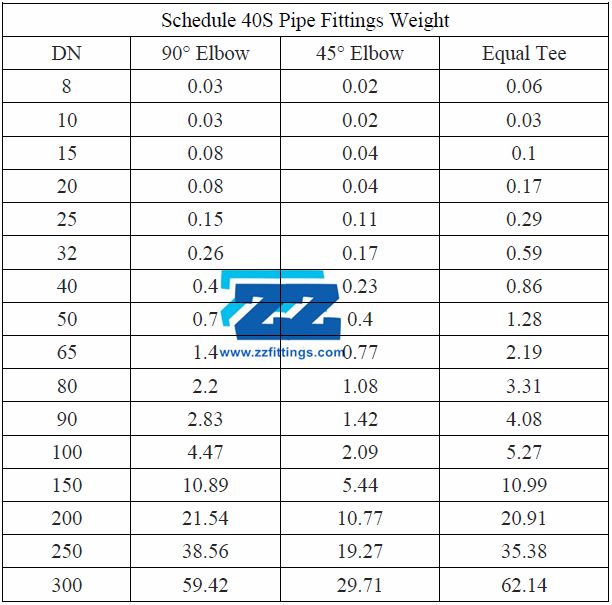

Schedule 40S Pipe Fittings Weight Chart

The common equal size butt weld fittings are 90 degree elbow, 45 degree elbow and equal tee. Due to the size range, the weight and volume is very important for calculating the transportation cost.

Equal Pipe Fittings Weight Chart

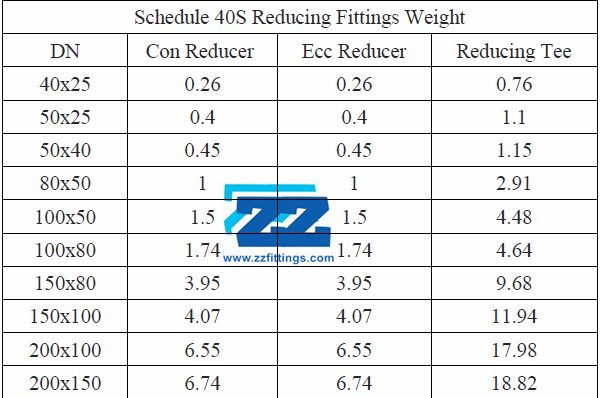

The unequal pipe fittings also called reducing fittings, these are concentric reducer, eccentric reducer & reducing tee, now we provide the weight chart as following. For more dimensions & weight, please contact us.

Reducing Fittings Weight Chart

ASTM A815 UNS S32750 Properties

Chemical Properties

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| 2507 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24 – 26 | 3 – 5 | 6 – 8 |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| 2507 | 795 (MPA) | 550 (MPA) | 15% | 310 (HB) |

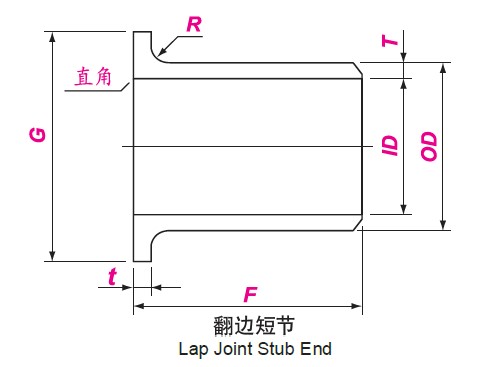

Drawing & Specification for Lap Joint Stub End

Lap Joint Stub End Drawing

- When the short type is used on the large flanges with PN 50 and PN 110(300 and 600LB)and on flanges

with PN 150(900LB)and above,or the long type is used on the larger flange with PN260 and PN420(1500 and 2500LB),the length of the cylinder may be added to be added to be feasible the welding,the adding length shall be negotiated by manufacturer and purchaser. - The thickness of joint shall be added if the TG and MFM contact surface of flange are used, and the adding thickness shall increase (not be included in)the base length F.

- The radius of fillet R(type A)shall conform to the ones of loose flanges according to GB/T 9118.1~9118.2 or ASME B16.5.The radius of fillet R(type B)is only applied for the standards of MSS SP-43 with short length F.

- The lap joint diameter G shall conform to the standard machined face indicated in ASME B16.5,and the back of joint shall be machined to conform to the surface of installation.When RJ used,the size K specified in ASME B 16.5 Shall apply.

- The minimum lap joint thickness t shall not be less than the nominal pipe wall thickness.

| Nominal Size | OD of Cylinder | Length | Radius of Fillet | Diameter of Lap | ||||

|---|---|---|---|---|---|---|---|---|

| DN | NPS | OD | F | R | ||||

| Max. | Min. | Long | Short | A | B | G | ||

| 15 | 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 0.8 | 35 |

| 20 | 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 0.8 | 43 |

| 25 | 1 | 35.0 | 32.6 | 102 | 51 | 3 | 0.8 | 51 |

| 32 | 1 1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 0.8 | 64 |

| 40 | 1 1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 0.8 | 73 |

| 50 | 2 | 62.4 | 59.5 | 152 | 64 | 8 | 0.8 | 92 |

| 65 | 2 1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 0.8 | 105 |

| 80 | 3 | 91.3 | 88.1 | 152 | 64 | 10 | 0.8 | 127 |

| 90 | 3 1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 0.8 | 140 |

| 100 | 4 | 116.7 | 113.5 | 152 | 76 | 11 | 0.8 | 157 |

| 125 | 5 | 144.3 | 140.5 | 203 | 76 | 11 | 1.6 | 186 |

| 150 | 6 | 171.3 | 167.5 | 203 | 89 | 13 | 1.6 | 216 |

| 200 | 8 | 222.1 | 218.3 | 203 | 102 | 13 | 1.6 | 270 |

| 250 | 10 | 227.2 | 272.3 | 254 | 127 | 13 | 1.6 | 324 |

| 300 | 12 | 328.0 | 323.1 | 254 | 152 | 13 | 1.6 | 381 |

| 350 | 14 | 359.9 | 354.8 | 305 | 152 | 13 | 1.6 | 413 |

| 400 | 16 | 411.0 | 405.6 | 305 | 152 | 13 | 1.6 | 470 |

| 450 | 18 | 462.0 | 456.0 | 305 | 152 | 13 | 1.6 | 533 |

| 500 | 20 | 514.0 | 507.0 | 305 | 152 | 13 | 1.6 | 584 |

| 550 | 22 | 565.0 | 558.0 | 305 | 152 | 13 | 1.6 | 64 |

| 600 | 24 | 616.0 | 609.0 | 305 | 152 | 13 | 1.6 | 692 |

Socket Weld Reducing Tee

1 x 1 x 1/2 Socket Weld Reducing Tee Class 6000 ASTM A182 F316 ASME B16.11

USD21 USD20

A182 F316 Threaded Coupling

Full Coupling Threaded 3000 LB BSPP 1 1/2" ASTM A182 F316 ASME B16.11

USD37 USD35