- Home

- Blog Custom Layout

- Steel Pipe Reducers

- Carbon Steel Pipe Reducer

Carbon Steel Pipe Reducer

USD39 USD38

Concentric Reducer 10" x 8" STD SMLS BE ASTM A420 WPL6

- General Details

- Technical Info

- Specification

- Documents

- Related Products

Carbon steel pipe reducer is one type of buttweld fittings in material grades ASTM A234 WPB, A860 WPHY 65 and A420 WPL6 for low temperature service. The other butt weld fittings also can be delivered in a short time, such as elbow, tee, cross and cap. What is the difference? Pipe reducer has one connection method that BW only. Not like them, also have socket weld and threaded types.

Types of Carbon Steel Pipe Reducer

Carbon Steel Concentric Reducer

Concentric Reducer

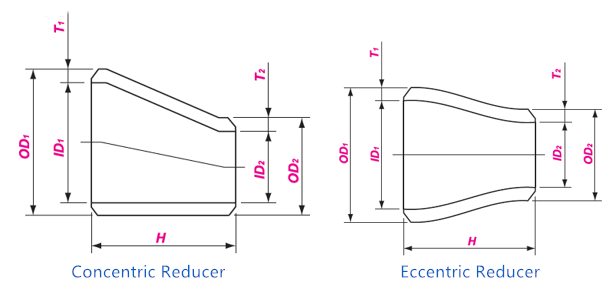

The concentric reducer is made with both inlet and outlet on a common center line. Compare with eccentric type, it is less costly to manufacture adaptable to most piping installations.

Carbon Steel Eccentric Reducer

Eccentric Reducer

The eccentric reducer has the reducing outlet end off center. In contrast with concentric reducer, that can be hung or suspended flush against a flat ceiling or wall.

Specification for ASTM A234 Pipe Fittings

Specification: ASTM A234 / ASME SA234

Size: 1/2″, 1″, 2″, 3″, 4″, 6″, 8″, 10″, 12″, 16″, 20″, 24″ to 60″

Schedule: Sch 20, STD, Sch 40, XS, Sch 80, Sch 160, XXS

End: Plain or Bevel

Type: Seamless and Welded Pipe Reducer

Material & Grades

ASTM A234 WPB Concentric Reducer

A420 WPL6 Eccentric Reducer

A860 WPHY 42/46/52/56/60/65/70 Pipe Reducer

Butt Weld Reducer Weight Chart

The weight chart is available in concentric and eccentric reducer which based on the ASME / ANSI B16.9 . The weight for the size more than DN1200 (NPS 48) is calculated on the basis of thickness 9.53mm.

| Nominal Size | SCH20 | STD | SCH40 | SCH80 | SCH120 | SCH160 | |

| DN | NPS | ||||||

| 15 | 1/2 | 0.08 | 0.08 | 0.1 | |||

| 20 | 3/4 | 0.17 | 0.17 | 0.2 | |||

| 25 | 1 | 0.21 | 0.21 | 0.25 | 0.22 | ||

| 32 | 1 1/4 | 0.29 | 0.29 | 0.35 | |||

| 40 | 1 1/2 | 0.42 | 0.42 | 0.58 | 0.6 | ||

| 50 | 2 | 0.8 | 0.8 | 1.03 | 1.04 | ||

| 65 | 2 1/2 | 1.05 | 1.05 | 1.42 | 1.65 | ||

| 80 | 3 | 1.36 | 1.36 | 1.9 | |||

| 90 | 3 1/2 | 1.63 | 1.63 | 2.27 | 2.4 | ||

| 100 | 4 | 2.77 | 2.77 | 3.93 | 4.4 | ||

| 125 | 5 | 3.96 | 3.96 | 6 | 7.14 | ||

| 150 | 6 | 6.31 | 6.31 | 9.26 | 10.8 | ||

| 200 | 8 | 7.85 | 10.7 | 10.7 | 17.5 | 15 | 18.4 |

| 250 | 10 | 11.2 | 15.8 | 16.3 | 25.1 | 25.1 | 32.5 |

| 300 | 12 | 25.6 | 28.8 | 32.1 | 56.5 | 41.7 | 53.3 |

| 350 | 14 | 30.5 | 38.5 | 48.8 | 79 | 84.5 | 106 |

| 400 | 16 | 35.2 | 44.5 | 64.3 | 102 | 112 | 143 |

| 450 | 18 | 62.7 | 62.7 | 98.5 | 165 | ||

| 500 | 20 | 72.6 | 72.6 | 181 | |||

| 550 | 22 | 97 | 79.1 | 142 | 226 | ||

| 600 | 24 | 130 | 100 | ||||

What is Buttweld Pipe Reducer?

Steel pipe reducer is used in piping system to change the diameter of pipe. ANSI / ASME B16.9 Butt weld pipe reducer is an pipe connector or pipe joint that reduces the size of pipe from larger diameter to smaller. The reduction in size is mainly equal to the average smaller and larger pipe diameter. It comes in two types that Concentric Reducer and Eccentric Reducer. The Concentric Pipe Reducer is used in vertical piping system. The Eccentric Pipe Reducer is used in horizontal piping system.

ASTM A420/ASME SA 420 Properties

Chemical Properties

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| WPL6 | 0.30 | 0.15-0.40 | 0.50-1.35 | 0.035 | 0.040 | 0.30 | 0.40 | 0.12 |

| WPL9 | 0.20 | / | 0.40-1.06 | 0.030 | 0.030 | / | 1.60-2.24 | / |

| WPL3 | 0.20 | 0.13-0.37 | 0.31-0.64 | 0.05 | 0.05 | / | 3.2-3.8 | / |

| WPL8 | 0.13 | 0.13-0.37 | 0.90 | 0.030 | 0.030 | / | 8.4-9.6 | / |

Mechanical Properties

| Grade | T.S. | Y.S. | EL. |

|---|---|---|---|

| WPL6 | 415-655 | 240 | 22 |

| WPL9 | 435-610 | 315 | 20 |

| WPL3 | 450-620 | 240 | 22 |

| WPL8 | 690-865 | 515 | 16 |

Drawings & Specification for Steel Pipe Reducer

Drawing for Butt Weld Reducer

1) Besides the above mentioned standards, the standards of GB/T 10752、SH 3408、SH 3409、HG/T 21635、HG/T 21631、SY/T 0510、DL/T 695、EN 10253 etc. are also applied.

2) For the concentric and eccentric reducers with the sizes larger than that listed in the above table, they will be supplied subject to the sizes agreed by purchaser and manufacturer or manufacturer’s size.

| Nominal Size | Outside Diameter at Bevel | End to End | |

| DN | NPS | OD×OD | H |

| 20×15 | 3/4×1/2 | 26.7×21.3 | 38 |

| 25×20 | 1×3/4 | 33.4×26.7 | 51 |

| 32×25 | 1 1/4×1 | 42.2×33.4 | 51 |

| 40×32 | 1 1/2×1 1/4 | 48.3×42.2 | 64 |

| 50×40 | 2×1 1/2 | 60.3×48.3 | 76 |

| 65×50 | 2 1/2×2 | 73.0×60.3 | 89 |

| 80×65 | 3×2 1/2 | 88.9×73.0 | 89 |

| 90×80 | 3 1/2×3 | 101.6×88.9 | 102 |

| 100×90 | 4×3 1/2 | 114.3×101.6 | 102 |

| 125×100 | 5×4 | 141.3×114.3 | 127 |

| 150×125 | 6×5 | 168.3×141.3 | 140 |

| 200×150 | 8×6 | 219.1×168.3 | 152 |

| 250×200 | 10×8 | 273.0×219.1 | 178 |

| 300×250 | 12×10 | 323.8×273.0 | 203 |

| 350×300 | 14×12 | 355.6×323.8 | 330 |

| 400×350 | 16×14 | 406.4×355.6 | 356 |

| 450×400 | 18×16 | 457.0×406.4 | 381 |

| 500×450 | 20×18 | 508.0×457.0 | 508 |

| 550×500 | 22×20 | 559.0×508.0 | 508 |

| 600×550 | 24×22 | 610.0×559.0 | 508 |

| 650×600 | 26×24 | 660.0×610.0 | 610 |

| 700×650 | 28×26 | 711.0×660.0 | 610 |

| 750×700 | 30×28 | 762.0×711.0 | 610 |

| 800×750 | 32×30 | 813.0×762.0 | 610 |

| 850×800 | 34×32 | 864.0×813.0 | 610 |

| 900×850 | 36×34 | 914.0×864.0 | 610 |

| 950×900 | 38×36 | 965.0×914.0 | 610 |

| 1000×950 | 40×38 | 1016.0×965.0 | 610 |

| 1050×1000 | 42×40 | 1067.0×1016.0 | 610 |

| 1100×1050 | 44×42 | 1118.0×1067.0 | 610 |

| 1150×1100 | 46×44 | 1168.0×1118.0 | 711 |

| 1200×1150 | 48×46 | 1219.0×1168.0 | 711 |

| 1300×1200 | 52×48 | 1321.0×1219.0 | 711 |

| 1400×1300 | 56×52 | 1422.0×1321.0 | 711 |

| 1500×1400 | 60×56 | 1524.0×1422.0 | 711 |