- Home

- Blog Custom Layout

- Steel Pipe Caps

- Carbon Steel Pipe Cap

Carbon Steel Pipe Cap

USD10 USD8

Carbon Steel BW & Socket Weld & Threaded Cap ASME B16.9 & B16.11

Carbon steel pipe cap is also known as head cap which is used to weld or install on the male thread of end of pipes for blocking the pipelines. It has same function as plug and blind flange.

Steel pipelines includes pipes, fittings, flanges, gaskets, valves, bolts and nuts. It is important to select proper piping material to ensure system safety and durability at appropriate cost.

We can produce pipe fittings & flanges in customized size as per customer required. Usually stock the dimensions in accordance with standards of ASME B16.9, B16.5, B16.11 & BS3799. Our goods are good for waterproof the connections to avoid leakage, and laso can work high pressure and temperature situation.

Types of Carbon Steel Pipe Cap

- Carbon Steel Butt Weld Cap

- Stainless Steel Socket Weld Cap

- Carbon Steel Threaded Pipe Cap

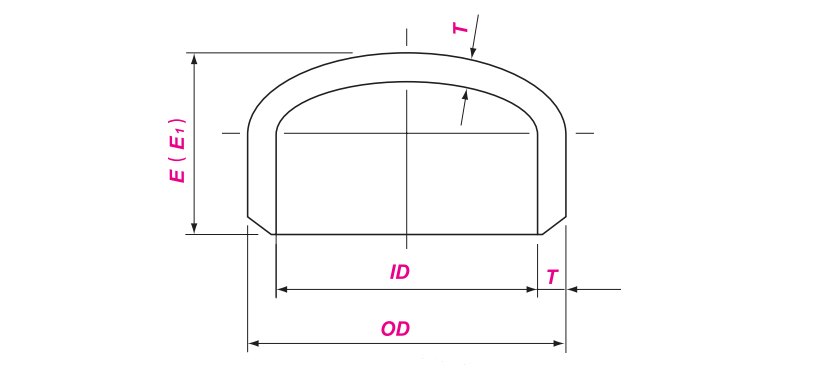

ASME B16.9 End Cap Dimensions

ANSI / ASME B16.9 Standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought factory-made butt-welding fittings in sizes NPS 1/2 through 48 (DN 15 through 1200) and thickness Schedule 10, 20, 30, STD, 40, 60, XS, 80, 100,120,140,160, XXS.

Buttwelding Cap Drawing

| DN | NPS | OD | E | E1 |

|---|---|---|---|---|

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 38 | 38 |

| 40 | 1 1/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 2 1/2 | 73 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 3 1/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273 | 127 | 152 |

| 300 | 12 | 323.9 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457 | 203 | 229 |

| 500 | 20 | 508 | 229 | 254 |

| 550 | 22 | 558.8 | 254 | 254 |

| 600 | 24 | 609.6 | 267 | 305 |

| 650 | 26 | 660.4 | 267 | – |

| 700 | 28 | 711.2 | 267 | – |

| 750 | 30 | 762 | 267 | – |

| 800 | 32 | 812.8 | 267 | – |

| 850 | 34 | 863.6 | 267 | – |

| 900 | 36 | 914.4 | 267 | – |

| 950 | 38 | 965.2 | 305 | – |

| 1000 | 40 | 1016 | 305 | – |

| 1050 | 42 | 1066.8 | 305 | – |

| 1100 | 44 | 1117.8 | 343 | – |

| 1150 | 46 | 1168.4 | 343 | – |

| 1200 | 48 | 1219.2 | 343 | – |

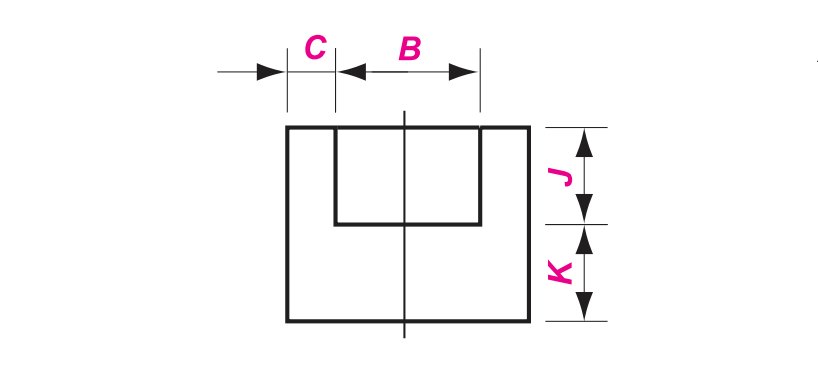

ASME B16.11 Socket Weld Cap Dimensions

ANSI / ASME B16.11 Standard covers ratings, dimensions, tolerances, marking and material requirements for socket-welding and threaded forged fittings. These fittings are designated as Class 2000, 3000, and 6000 for threaded pipe fittings and Class 3000, 6000, and 9000 for socket weld fittings. B16.11 is to be used in conjunction with equipment described in other volumes of the ASME B16 series of standards as well as with other ASME standards, such as the Boiler and Pressure Vessel Code and the B31 Piping Codes.

Socket Weld Cap Drawing

| DN | NPS | B | C | J | K | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||

| ave | min | ave | min | ave | min | |||||||

| 6 | 1/8 | 10.9 | 3.18 | 3.18 | 3.96 | 3.43 | 9.5 | 4.8 | 6.4 | |||

| 8 | 1/4 | 14.3 | 3.78 | 3.3 | 4.6 | 4.01 | 9.5 | 4.8 | 6.4 | |||

| 10 | 3/8 | 17.7 | 4.01 | 3.5 | 5.03 | 4.37 | 9.5 | 4.8 | 6.4 | |||

| 15 | 1/2 | 21.9 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 9.5 | 6.4 | 7.9 | 11.2 |

| 20 | 3/4 | 27.3 | 4.9 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 6.4 | 7.9 | 12.7 |

| 25 | 1 | 34 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 9.6 | 11.2 | 14.2 |

| 32 | 1 1/4 | 42.8 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 9.6 | 11.2 | 14.2 |

| 40 | 1 1/2 | 48.9 | 6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 12.5 | 11.2 | 12.7 | 15.7 |

| 50 | 2 | 61.2 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 16 | 12.7 | 15.7 | 19 |

| 65 | 2 1/2 | 73.9 | 8.76 | 7.62 | 16 | 15.7 | 19 | |||||

| 80 | 3 | 89.9 | 9.52 | 8.3 | 16 | 19 | 22.4 | |||||

| 100 | 4 | 115.5 | 10.69 | 9.35 | 19 | 22.4 | 28.4 | |||||

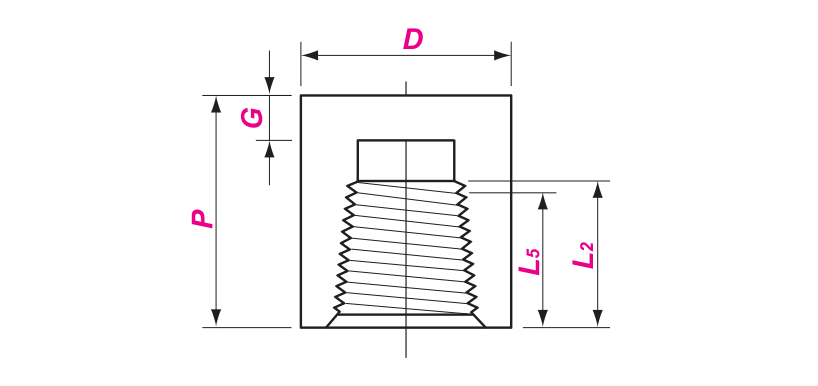

Threaded Cap Drawing

Threaded Pipe Cap Dimensions

| DN | NPS | P | D | G | L5 | L2 | |||

|---|---|---|---|---|---|---|---|---|---|

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 19 | – | 16 | 22 | 4.8 | – | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1 1/4 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17 | 18 |

| 40 | 1 1/2 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19 | 19.2 |

| 65 | 2 1/2 | 60 | 64 | 92 | 108 | 15.7 | 19 | 23.6 | 28.9 |

| 80 | 3 | 65 | 68 | 108 | 127 | 19 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33 |

Forged Carbon Steel Cap

Forged carbon steel fittings caps are made from steel rod by forging, there are two connection types that socket weld and screwed. The orignal material material grades are ASTM A105, ASTM A350 LF2 / LF3, A694 F42, F46, F50, F52, F56, F60, F65, F70.

The surface coating can be hot dip galvanized and cold galvanized, the hot dip galvanizing have long life but not pretty, while cold galvanizing oppositly.

Chemical Composition

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Cu | N | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A105 | 0.35 | 0.6-1.05 | 0.035 | 0.04 | 0.1-0.35 | 0.4 | 0.3 | 0.12 | 0.4 | – | 0.08 |

| A350 LF2 | 0.3 | 0.6-1.35 | 0.035 | 0.04 | 0.15-0.30 | 0.4 | 0.3 | 0.12 | 0.4 | 0.02 | 0.08 |

| A350 LF3 | 0.2 | 0.9 | 0.035 | 0.04 | 0.2-0.35 | 3.3-3.7 | 0.3 | 0.12 | 0.4 | 0.02 | 0.03 |

| A694 F42 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F46 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F50 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F52 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F56 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F60 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F65 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

| A694 F70 | 0.3 | 1.6 | 0.025 | 0.025 | 0.15-0.35 | – | – | – | – | – | – |

Mechnical Properties

| Grade | Y.S (Mpa) | T.S (Mpa) | EL (%) |

|---|---|---|---|

| ASTM A105 | 250 | 485 | 22 |

| A350 LF2 | 205 | 415-585 | 22 |

| A350 LF3 | 250 | 485-655 | 22 |

| A694 F42 | 290 | 415 | 20 |

| A694 F46 | 315 | 415 | 20 |

| A694 F50 | 345 | 440 | 20 |

| A694 F52 | 360 | 455 | 20 |

| A694 F56 | 385 | 470 | 20 |

| A694 F60 | 415 | 515 | 20 |

| A694 F65 | 450 | 530 | 20 |

| A694 F70 | 485 | 565 | 18 |

Carbon Steel Buttwelding Cap

Carbon steel butt weld pipe caps are made from steel plate. It connects steel pipe by welding and the diameter size of pipe cap is larger than forged steel cap. There are many grades such as ASTM A234 WPB / WPC, WPL6 / 3 / 9, A860 WPHY 42 / 46 / 52 / 60 / 65 /70.

Usually we use coating of primer and galvaning on buttweld cap against rust. The primer could be normal, FBE, EPOXY RESIN, while the galvaning is hot dip type.

Chemical Composition

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Cu | Ti | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A234 WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1 min | 0.4 | 0.4 | 0.15 | 0.4 | – | 0.08 |

| A234 WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1 min | 0.4 | 0.4 | 0.15 | 0.4 | – | 0.08 |

| A420 WPL6 | 0.3 | 0.5-1.35 | 0.035 | 0.04 | 0.15-0.4 | 0.4 | 0.3 | 0.12 | 0.4 | – | 0.08 |

| A420 WPL3 | 0.2 | 0.31-0.64 | 0.05 | 0.05 | 0.13-0.37 | 3.2-3.8 | – | – | – | – | – |

| A420 WPL9 | 0.2 | 0.4-1.06 | 0.03 | 0.03 | – | 1.6-2.24 | – | – | 0.75-1.25 | – | – |

| A860 WPHY42 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

| A860 WPHY46 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

| A860 WPHY52 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

| A860 WPHY60 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

| A860 WPHY65 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

| A860 WPHY70 | 0.2 | 1-1.45 | 0.03 | 0.01 | 0.15-0.4 | 0.5 | 0.3 | 0.25 | 0.35 | 0.05 | 0.1 |

Mechnical Properties

| Grade | Y.S (Mpa) | T.S (Mpa) | EL (%) |

|---|---|---|---|

| A234 WPB | 240 | 415-655 | 22 |

| A234 WPC | 275 | 485-655 | 22 |

| A420 WPL6 | 240 | 415-655 | 22 |

| A420 WPL3 | 250 | 450-620 | 22 |

| A420 WPL9 | 315 | 435-610 | 20 |

| A860 WPHY42 | 290 | 415 | 20 |

| A860 WPHY46 | 315 | 415 | 20 |

| A860 WPHY52 | 360 | 455 | 20 |

| A860 WPHY60 | 415 | 515 | 20 |

| A860 WPHY65 | 450 | 530 | 20 |

| A860 WPHY70 | 485 | 565 | 18 |