- Home

- Blog Custom Layout

- Steel Pipe Elbows

- Carbon Steel Elbow

Carbon Steel Elbow

USD2.5 USD2

Carbon Steel Elbow 90 Degree BW & SW 1" Sch 80

- General Details

- Technical Info

- BW Specification

- Documents

- Related Products

Carbon steel elbow is a weldable & threaded pipe fitting that allows for change of flow direction, we manufactured them as standard of ASME B16.9 and B16.11. ASTM A234 WPB Elbow is the common used in the oil and gas industires.

We have supplied our buttweld fittings to major customers which business in Oil & Gas, Chemical & Petrochemical, Water treatment, Nuclear & Power Plant, Offshore platform & Shipbuilding. Our products are applicable for any kinds of severe operating condition such as high pressure and high temperature or cryogenic condition.

Supply Range of Carbon Steel Pipe Elbow

Standard: ASME B16.9, SH3408, HG/T21635, SY/T0510

Size: NPS 1/2″ to 48″ / DN 15 to 1200

Schedule: Sch 20, 40, STD, 80, 160, XXS

Designation: ASTM / ASME A234, A860, A420

Grade: WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3, 6, 9

Type: Seamless Elbow and Weld Elbow

Carbon Steel Chemical Properties

The common used carbon steel grades are ASTM A234 WPB and A420 WPL6 For low temperature service.

| Grade | C | Mn | Si | S | P |

| A234 WPB | ≤0.3 | 0.29 – 1.06 | 0.1 | ≤0.058 | ≤0.05 |

| A420 WPL6 | ≤0.3 | 0.6 – 1.35 | 0.15 – 0.3 | ≤0.04 | ≤0.035 |

Long Radius Elbow

Fittings that change direction in a piping system are called elbows which available in 90 degree and 45 degree long radius elbow. Both of them has the center line at 1.5 x NPS from elbow end.

Long Radius vs Short Radius

Short Radius Elbow

Short radius elbow almost same as above long radius, the difference is center line to end is 1 x NPS and available in 90 degree only.

Surface of Carbon Steel Elbow

Painting

Firstly, we do the blasting on the body of elbow, to clean the dirt things. Then paint the primer on the inner and outer side. The mainly purpose is against rust during the shipment.

Clean the steel pipe elbow body and wrap the polyethylene tape on it with adhesive. Usually the thickness of coating is 2mm. They are used in the underground pipeline system.

Take carbon steel buttweld fittings into a bath of molten zinc. That would get more zinc and make the price is high.

We surfaced carbon steel forged fittings with electrogalvanizing because it is pretty and low cost.

Carbon Steel Grades & Properties

| Grade | C | Mn | Si | S | P |

|---|---|---|---|---|---|

| A234 WPB | ≤0.3 | 0.29-1.06 | ≤0.1 | ≤0.058 | ≤0.05 |

| A105 | ≤0.35 | 0.6-1.0 | 0.1-0.35 | ≤0.04 | ≤0.035 |

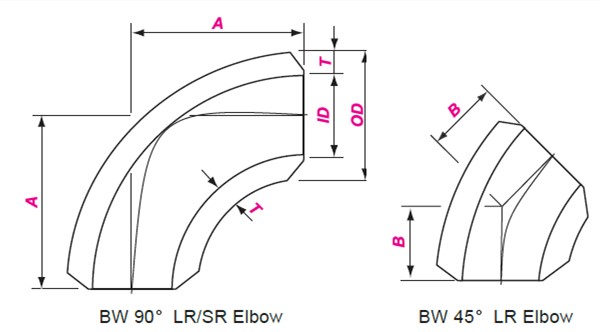

Drawing & Specification for BW Elbow

Butt Weld Elbow Drawing

| Nominal Diameter | Outside Diameter at Bevel | A | B | ||

|---|---|---|---|---|---|

| DN | NPS | OD | Long Radius | Short Radius | Long Radius |

| 15 | 1/2 | 21.3 | 38 | – | 16 |

| 20 | 3/4 | 26.9 | 38 | – | 19 |

| 25 | 1 | 33.7 | 38 | 25 | 22 |

| 32 | 1 1/4 | 42.4 | 48 | 32 | 25 |

| 40 | 1 1/2 | 48.3 | 57 | 38 | 29 |

| 50 | 2 | 60.3 | 76 | 51 | 35 |

| 65 | 2 1/2 | 73 | 95 | 64 | 44 |

| 80 | 3 | 88.9 | 114 | 76 | 51 |

| 90 | 3 1/2 | 101.6 | 133 | 89 | 57 |

| 100 | 4 | 114.3 | 152 | 102 | 64 |

| 125 | 5 | 139.7 | 190 | 127 | 79 |

| 150 | 6 | 168.3 | 229 | 152 | 95 |

| 200 | 8 | 219.1 | 305 | 203 | 127 |

| 250 | 10 | 273 | 381 | 254 | 159 |

| 300 | 12 | 323.9 | 457 | 305 | 190 |

| 350 | 14 | 355.6 | 533 | 356 | 222 |

| 400 | 16 | 406.4 | 610 | 406 | 254 |

| 450 | 18 | 457.2 | 686 | 457 | 286 |

| 500 | 20 | 508 | 762 | 508 | 318 |

| 550 | 22 | 559 | 838 | 559 | 343 |

| 600 | 24 | 610 | 914 | 610 | 381 |

| 650 | 26 | 660 | 991 | 660 | 406 |

| 700 | 28 | 711 | 1067 | 711 | 438 |

| 750 | 30 | 762 | 1143 | 762 | 470 |

| 800 | 32 | 813 | 1219 | 813 | 502 |

| 850 | 34 | 864 | 1295 | 864 | 533 |

| 900 | 36 | 914 | 1372 | 914 | 565 |

| 950 | 38 | 965 | 1448 | 965 | 600 |

| 1000 | 40 | 1016 | 1524 | 1016 | 632 |

| 1050 | 42 | 1067 | 1600 | 1067 | 660 |

| 1100 | 44 | 1118 | 1676 | 1118 | 695 |

| 1150 | 46 | 1168 | 1753 | 1168 | 727 |

| 1200 | 48 | 1220 | 1829 | 1220 | 759 |

| 1300 | 52 | 1321 | 1981 | 1321 | 821 |

| 1400 | 56 | 1422 | 2134 | 1422 | 883 |

| 1500 | 60 | 1524 | 2286 | 1524 | 947 |

| 1600 | 64 | 1626 | 2438 | 1626 | 1010 |

| 1700 | 68 | 1727 | 2591 | 1727 | 1073 |

| 1800 | 72 | 1829 | 2743 | 1829 | 1137 |

| 1900 | 76 | 1930 | 2896 | 1930 | 1199 |

| 2000 | 80 | 2032 | 3048 | 2032 | 1263 |

Threaded Socket & Coupling

Threaded socket coupling 1 1/2" Class 3000 BSPP SS316 ASME B16.11

USD30 USD28

Threaded Pipe Nipples

Nipple 1/2" Sch 80 BSPP TBE L=100MM Galvanized API 5LB ASME B16.11

USD2.5 USD2