- Home

- Blog Custom Layout

- Steel Pipe Bends

- Bend Pipe Fittings

Bend Pipe Fittings

- General Details

- Technical Info

- DWG & SPEC

- Related Products

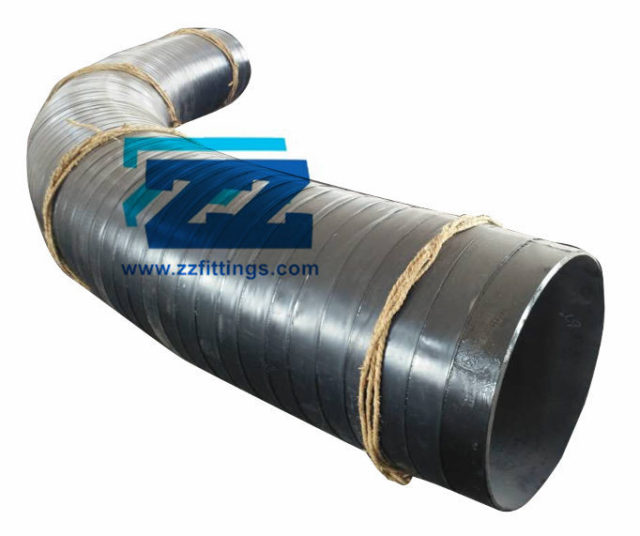

Steel pipe bend is a pipe fittings which used to change direction of the pipeline for some specific reason. The manufacturing are cold and hot heating. While Bending pipe in the heating process, the heating process should be slow and uniform, so as to ensure the thermal conductivity of the pipe, we should pay attention to avoid overheating and carburizing.

What is Industrial Processes for Bend Pipe Fittings?

Bending, squeezing, pressing, forging, machining and more.

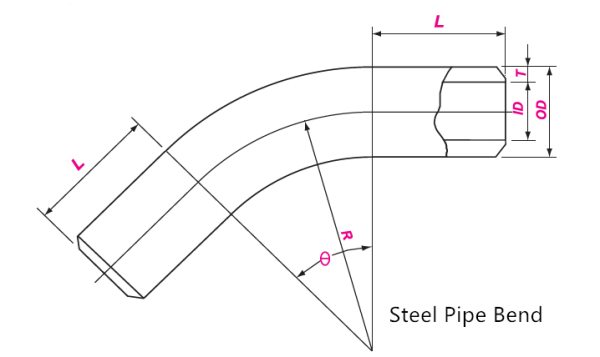

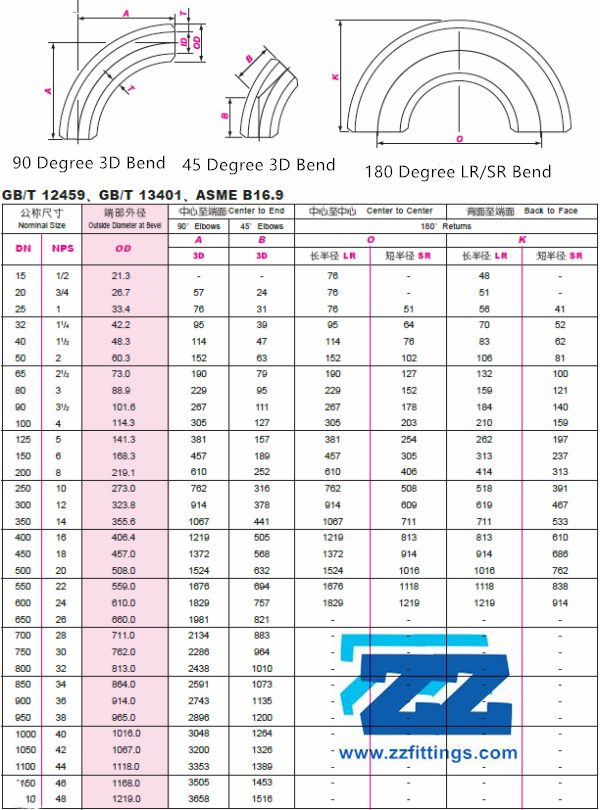

Steel Pipe Bend Dimensions

Bending Radius

R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) D means outside diameter.

What is Bend Angle?

Normally 15°, 30°, 45°, 60°, 90°, 135°, 180° or at customer’s option.

Straight Length (L) for Bend

Normally between 300mm and 1500mm in length of straight. It is also at customer’s option.

Application of Buttweld Elbow & Bend

Buttweld elbows & bends are widely used in many industries, such as power generation, petroleum, natural gas, chemicals, shipbuilding, heating, paper-making, metallurgy and so on.

Weight formula of Bend Pipe Fittings

Weight / kg = 0.0433 ( D – T ) TRθ / 100000 + L

D = Outside diameter

T = Thickness in mm

R = Bend radius

θ = Bend angle

L = Weight of double sides straight length

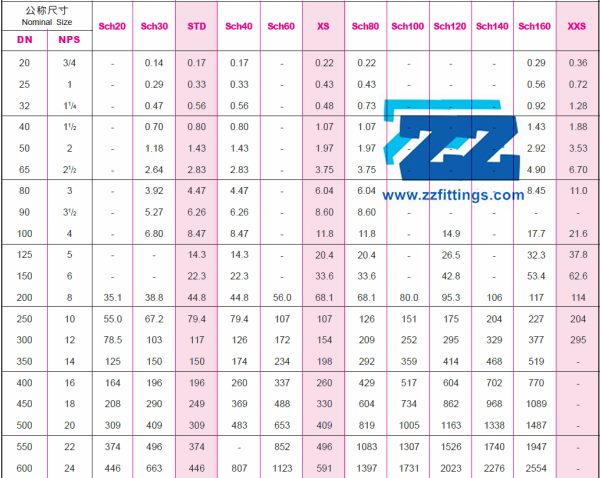

3D Bend Weight Chart

Weight Chart of 3D Bend

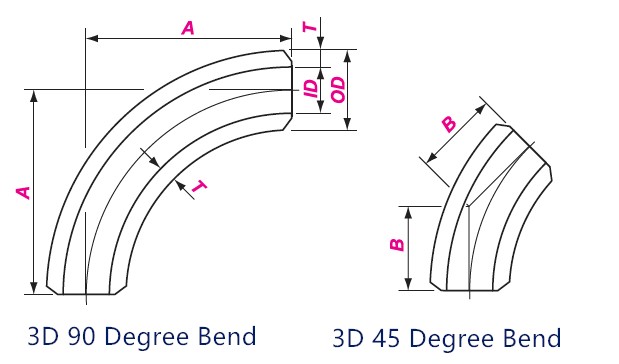

3D Bend Dimensions

Standard: ASME B16.9, DL/T515, SY5257

Size: DN 15 to 1200 / NPS 1/2 to 48

Thickness : ≤120mm

Angle: 45 °, 90°, 180 °

Material: Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel.

3D Bend Dimensions

Carbon Steel Pipe Bend

ASTM A106B, A53B, API 5L B, API 5L X42, X52, X60, X65, X70, A333 GRADE 3 / 6 / 9

Alloy Steel Bend and Elbow

ASTM A335 P1, P5, P9, P11, P12, P22, P91

Stainless Steel Bend Pipe Fittings

ASTM A312 TP304/304L/304H, TP316/316L, TP310, TP317, TP321, TP309, TP347

Duplex Steel 5D Bend

ASTM A815 UNS S31803, S32205, S32550, S32750, S32760

What is Difference between Pipe Elbow and Bend?

Pipe bends typically have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than 1.5R, it is called Elbow. For example, 1.5D elbow we call it as long radius ( LR) elbow and 1D elbow as short radius ( SR) elbow.

API 5L X52 X56 X60 X65 X 70 Properties

Chemical Properties

| Grade | C | Si | Mn | P | S | V | Nb | Ti |

|---|---|---|---|---|---|---|---|---|

| API 5L X52 | 0.16 | 0.45 | 1.65 | 0.02 | 0.01 | 0.07 | 0.05 | 0.04 |

| API 5L X56 | 0.16 | 0.45 | 1.65 | 0.02 | 0.01 | 0.07 | 0.05 | 0.04 |

| API 5L X60 | 0.16 | 0.45 | 1.65 | 0.02 | 0.01 | 0.08 | 0.05 | 0.04 |

| API 5L X65 | 0.16 | 0.45 | 1.65 | 0.02 | 0.01 | 0.09 | 0.05 | 0.06 |

| API 5L X70 | 0.17 | 0.45 | 1.75 | 0.02 | 0.01 | 0.1 | 0.05 | 0.06 |

Mechanical Properties

| Grade | Yield Strength Min. (MPA) |

Tensile Strength Min. (MPA) |

Elongation % |

|---|---|---|---|

| API 5L X52 | 355 | 450 | 21 |

| API 5L X56 | 385 | 485 | 19 |

| API 5L X60 | 410 | 515 | 19 |

| API 5L X65 | 450 | 530 | 18 |

| API 5L X70 | 480 | 560 | 17 |

Drawing & Specification for 3D Bend

3D Bend Drawing

| Nominal Size | Center to End | Center to Center | Back to Face | |||||

|---|---|---|---|---|---|---|---|---|

| 90°Bend | 45°Bend | 180°Returns | ||||||

| DN | NPS | OD | A | B | O | K | ||

| 3D | 3D | LR | SR | LR | SR | |||

| 15 | 1/2 | 21.3 | 76 | 48 | ||||

| 20 | 3/4 | 26.7 | 57 | 24 | 76 | 51 | ||

| 25 | 1 | 33.4 | 76 | 31 | 76 | 51 | 56 | 41 |

| 32 | 1 1/4 | 42.2 | 95 | 39 | 95 | 64 | 70 | 52 |

| 40 | 1 1/2 | 48.3 | 114 | 47 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 152 | 63 | 152 | 102 | 106 | 81 |

| 65 | 2 1/2 | 73 | 190 | 79 | 190 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 229 | 95 | 229 | 152 | 159 | 121 |

| 90 | 3 1/2 | 101.6 | 267 | 111 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 305 | 127 | 305 | 203 | 210 | 159 |

| 125 | 5 | 141.3 | 381 | 157 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 457 | 189 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 610 | 252 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273 | 762 | 316 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.8 | 914 | 378 | 914 | 609 | 619 | 467 |

| 350 | 14 | 355.6 | 1067 | 441 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 1219 | 505 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457 | 1372 | 568 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508 | 1524 | 632 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | 1676 | 694 | 1676 | 1118 | 1118 | 838 |

| 600 | 24 | 610 | 1829 | 757 | 1829 | 1219 | 1219 | 914 |

| 650 | 26 | 660 | 1981 | 821 | ||||

| 700 | 28 | 711 | 2134 | 883 | ||||

| 750 | 30 | 762 | 2286 | 964 | ||||

| 800 | 32 | 813 | 2438 | 1010 | ||||

| 850 | 34 | 864 | 2591 | 1073 | ||||

| 900 | 36 | 914 | 2743 | 1135 | ||||

| 950 | 38 | 965 | 2896 | 1200 | ||||

| 1000 | 40 | 1016 | 3048 | 1264 | ||||

| 1050 | 42 | 1067 | 3200 | 1326 | ||||

| 1100 | 44 | 1118 | 3353 | 1389 | ||||

| 1150 | 46 | 1168 | 3505 | 1453 | ||||

| 1200 | 48 | 1219 | 3658 | 1516 | ||||

Large Diameter Steel Pipe Cap

Seamless Steel Pipe Cap BE 20" x 8mm BW ASTM A234 WPB ASME B16.9

USD50 USD48

Sch 80 Concentric Reducer

10 x 8 Inch Sch 80 Concentric Reducer SMLS ASTM A860 WPHY50 ASME B16.9

USD46 USD43

Galvanized 90 Degree Elbow

Galvanized 1 Inch BSPP 3000# 90 Degree Elbow ASTM A694 F52 ASME B16.11

USD6 USD5

WPHY 60 Pipe Fittings

ASTM A860 WPHY 60 Pipe Fittings 1/2" to 80" Sch 20, STD, 40, XS, 80, 120, 160

USD0.3-3200 USD0.2-3100