- Home

- Blog Custom Layout

- Duplex Steel Pipe Fittings

- A815 UNS S31803 Elbow Fittings

A815 UNS S31803 Elbow Fittings

USD1516 USD1488

12" ELBOW 90 DEGREE LR SMLS ASME B16.9 ASTM A815 UNS S31803 SCH60

- General Details

- Technical Info

- Video

- DWG & SPEC

- Documents

- Related Products

ASTM A815 UNS S31803 is specification for duplex stainless steel fittings of seamless and welded construction, it consists elbow, reducer, tee and stud end.

Quality leading manufacturer Zizi offers super duplex stainless steel butt weld fittings for Singapore. Seamless ppe fittings are available in a variety sizes and plays a important role in the piping system.

ASTM A815 Duplex Butt Weld Fittings are widely used diverse industries. Fittings and Flanges of S 31803 are made available on request of customers.

Duplex A815 UNS S31803 Elbow Fittings Dimensions

Duplex UNS S31803 Elbow Fittings Dimensions

Standard: ASME/ANSI B16.9

Size: 1/8″ to 24″

Thickness: Sch 10s, 20, STD, 40S, XS, 80S, 120, 160

Technical: Seamless and Weld Elbow

Surface: Pickling and Solution Heat Treatment.

Material Grades: UNS S 31803, S 32205, S 32550, S 32750, S 32760

What are Similar Grades to UNS S31803 Fittings

2205

EN 1.4462Z

UNS S31803

UNS S32205

BS 318S13

318

How Many Types of Steel Pipe Elbow?

- Angle

45 Degree Elbow, 90 Degree Elbow, 180 Degree Elbow.

- Shape

Straight Elbow and Reducing Elbow.

- Radius

Long Radius Elbow and Short Radius Elbow.

- Connection

Butt Weld Elbow, Socket Weld Elbow, Threaded Elbow.

Schedule 40 Elbow Weight in kg

| DN | NPS | WEIGHT |

| 15 | 1/2 | 0.08 |

| 20 | 3/4 | 0.11 |

| 25 | 1 | 0.15 |

| 32 | 1 1/4 | 0.25 |

| 40 | 1 1/2 | 0.39 |

| 50 | 2 | 0.66 |

| 65 | 2 1/2 | 1.37 |

| 80 | 3 | 2.19 |

| 90 | 3 1/2 | 2.96 |

| 100 | 4 | 4.12 |

| 125 | 5 | 6.89 |

| 150 | 6 | 10.7 |

| 200 | 8 | 21.6 |

| 250 | 10 | 37 |

| 300 | 12 | 61 |

| 350 | 14 | 85.1 |

| 400 | 16 | 121 |

| 450 | 18 | 176 |

| 500 | 20 | 232 |

| 550 | 22 | / |

| 600 | 24 | 377 |

How to Calculate Weight of 90 Degree Elbow

Calculation Formula : W=0.0387 * S( D – S ) * R / 1000

- W = Weight (kg/piece).

- S = Thickness in mm.

- D = Nominal Diameter in mm.

- R = Radius

For example” 90 Degree Elbow SR 10″ x 10mm Thickness BW ASTM A403 WP316 ASME B16.9″

From above information, we can know OD is 10″ which is 273mm. SR means 1D that is 1 x 273mm. Thickness is 10mm. Let’s take these data into formula.

0.0387 x 10 x (273 – 10) x 1 x 273 / 1000 = 27.8kg/pcs.

Duplex Steel Buttweld Fittings

Package

We marked Duplex Steel Buttweld Fittings with Grade, Heat No, Size, Standard and Thickness. Our workers wrapped ASTM A815 UNS S31803 Elbow with water-proof material, and put them into wooden case or pallets, then bundled packages with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

Inspection

- Visual the surface of duplex stainless steel elbow fittings.

- Check the marking. Such as size, material code, grade, thickness, heat No.

- Measure the diameter and thickness whether in tolerance.

- Test the chemical properties of ASTM A815 UNS S31803 Pipe Fittings.

Features

Duplex stainless steels are considered resistant to stress corrosion cracking, they are not as resistant to this form of attack as ferritic stainless steels. However, the corrosion resistance of the least resistant duplex stainless steels is much better than most commonly used grades of stainless steels 304 and 316.

UNS S31803 Properties

Chemical Composition

| C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.03 | 2 | 1 | 0.03 | 0.02 | 21-23 | 2.5-3.5 | 4.5-6.5 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|

| 620 (Mpa) | 450 (Mpa) | 25 (%) | 290 (HB) |

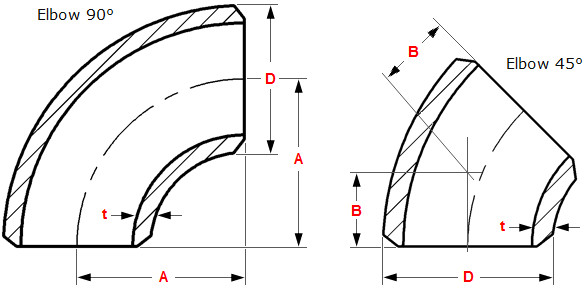

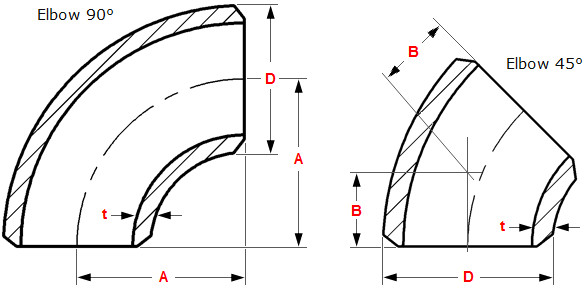

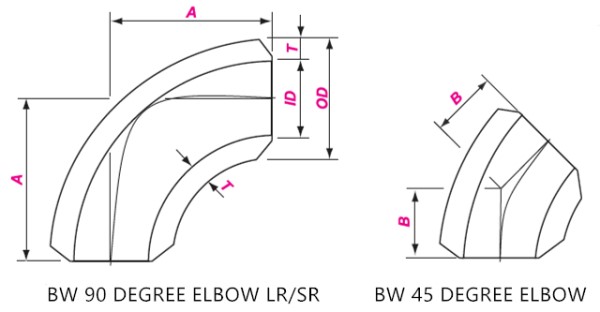

Duplex Stainless Steel Elbow

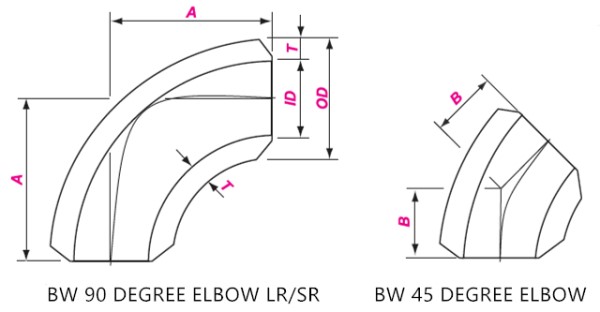

Drawing & Specification for 90 Degree & 45 Degree Elbow

They are also applied in SH3408, SH3409, HG/T 21635, HG/T21631, SY/T0510, DL/T695, EN 10253 besides ASME B16.9.

Dimensions for 90 Degree & 45 Degree Elbow

| Nominal Size | Outside Diameter at Bevel | Center to End | |||

|

|

||||

| A | B | ||||

| DN | NPS | OD | LR | SR | LR |

| 15 | 1/2 | 21.3 | 38 | – | 16 |

| 20 | 3/4 | 26.7 | 38 | – | 19 |

| 25 | 1 | 33.4 | 38 | 25 | 22 |

| 32 | 1 1/4 | 42.2 | 48 | 32 | 25 |

| 40 | 1 1/2 | 48.3 | 57 | 38 | 29 |

| 50 | 2 | 60.3 | 76 | 51 | 35 |

| 65 | 2 1/2 | 73 | 95 | 64 | 44 |

| 80 | 3 | 88.9 | 114 | 76 | 51 |

| 90 | 3 1/2 | 101.6 | 133 | 89 | 57 |

| 100 | 4 | 114.3 | 152 | 102 | 64 |

| 125 | 5 | 141.3 | 190 | 127 | 79 |

| 150 | 6 | 168.3 | 229 | 152 | 95 |

| 200 | 8 | 219.1 | 305 | 203 | 127 |

| 250 | 10 | 273 | 381 | 254 | 159 |

| 300 | 12 | 323.8 | 457 | 305 | 190 |

| 350 | 14 | 355.6 | 533 | 356 | 222 |

| 400 | 16 | 406.4 | 610 | 406 | 254 |

| 450 | 18 | 457 | 686 | 457 | 286 |

| 500 | 20 | 508 | 762 | 508 | 318 |

| 550 | 22 | 559 | 838 | 559 | 343 |

| 600 | 24 | 610 | 914 | 610 | 381 |

| 650 | 26 | 660 | 991 | 660 | 406 |

| 700 | 28 | 711 | 1067 | 711 | 438 |

| 750 | 30 | 762 | 1143 | 762 | 470 |

| 800 | 32 | 813 | 1219 | 813 | 502 |

| 850 | 34 | 864 | 1295 | 864 | 533 |

| 900 | 36 | 914 | 1372 | 914 | 565 |

| 950 | 38 | 965 | 1448 | 965 | 600 |

| 1000 | 40 | 1016 | 1524 | 1016 | 632 |

| 1050 | 42 | 1067 | 1600 | 1067 | 660 |

| 1100 | 44 | 1118 | 1676 | 1118 | 695 |

| 1150 | 46 | 1168 | 1753 | 1168 | 727 |

| 1200 | 48 | 1219 | 1829 | 1219 | 759 |

| 1300 | 52 | 1321 | 1981 | 1321 | 821 |

| 1400 | 56 | 1422 | 2134 | 1422 | 883 |

| 1500 | 60 | 1524 | 2286 | 1524 | 947 |

| 1600 | 64 | 1626 | 2438 | 1626 | 1010 |

| 1700 | 68 | 1727 | 2591 | 1727 | 1073 |

| 1800 | 72 | 1829 | 2743 | 1829 | 1137 |

| 1900 | 76 | 1930 | 2896 | 1930 | 1199 |

| 2000 | 80 | 2032 | 3048 | 2032 | 1263 |

ASTM A105 Reducing Tee Galvanized

Reducing Tee SW DN40 X DN32 Class 3000 Galvanized ASTM A105 ASME B16.11

USD19 USD18

ASTM A234 WPB Concentric Reducer

Concentric Reducer Seamless 3" x 2" Sch160 BW ASTM A234 GR WPB

USD9 USD8