- Home

- Blog Custom Layout

- A182 F316 Threaded Coupling

A182 F316 Threaded Coupling

USD37 USD35

Full Coupling Threaded 3000 LB BSPP 1 1/2" ASTM A182 F316 ASME B16.11

- General Details

- Technical Info

- Video

- DWG & SPEC

- Documents

- Related Products

ASTM A182 F316 Threaded Coupling Fittings are typically used in many industries including food processing, marine, oil & gas,and cooling water systems. Since they are forged into Class 3000 & 6000 high pressure ratings.

Quality manufacturer Zizi supplies Threaded Coupling 3000 LB BSPP 1 1/2″ ASTM A182 F316 ASME B16.11 with carbon steel A105 90 degree elbow for Indonesia. Screw couplings are short fittings that helps to extend or terminate a run pipe. It connects two pipes to each other.

Stainless steel pipe fittings are ideal for applications that involve chemicals or liquids that may be corrosive. Along with fighting corrosion, stainless steel pipe fittings will also prevent contamination making it useful to many professionals and those who seek durability and longevity.

Stainless Steel Threaded Fittings Dimensions

Standard: ASME/ANSI B16.11, BS3799, EN ISO 4144, EN 10241

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″

Pressure Ratings: 2000LB, 3000 LB, 6000 LB

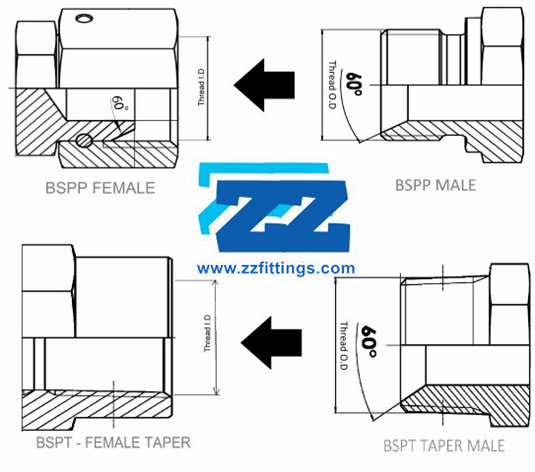

Thread Type: PF, PT, NPT, BSPP and BSPT

Surface: Pickling, Solution Heat Treatment and Anti-rust Oil.

Steel Pipe Coupling Types

Shape Types

Straight Coupling and Reducing Coupling.

Connection Types

Socket Weld Coupling and Threaded ( Screwed) Coupling.

Form Types

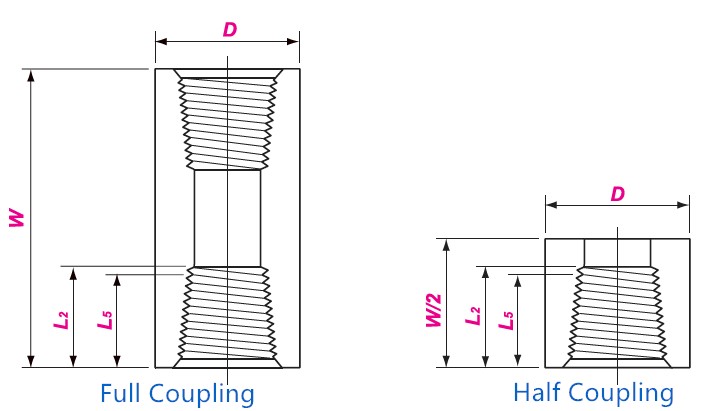

Full Coupling and Half Coupling

ASTM A182 F316 Meaning

ASTM A182 F316 is material grade for forged stainless steel flanges and fittings and supplied in the Solution Annealed condition.

Heat Treatment

The temperature of the forging is not less than the minimum solution temperature 1040℃ and rapidly quenched in 260℃. Heat treatment of forgings may be performed before machining.

Chemical Properties

| C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.035 | 2 | 0.75 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Reduction |

|---|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 30 (%) | 50 (%) |

Corrosion Resistance

ASTM 182 F316 has excellent corrosion resistance when exposed to a range of corrosive environments. However it is not resistant to warm sea water. That can cause pitting and crevice corrosion. It will also suffer from stress corrosion cracking above 60℃.

Class 3000 & 6000 Threaded Coupling Weight

Our screwed couplings are usually provided in high pressure and forging shape. Since they are small fittings, the weight can be used to check the air freight and courier cost.

| Nominal Size | Weight/kg | ||

|---|---|---|---|

| DN | NPS | 3000 | 6000 |

| 6 | 1/8 | 0.06 | 0.09 |

| 8 | 1/4 | 0.08 | 0.13 |

| 10 | 3/8 | 0.11 | 0.24 |

| 15 | 1/2 | 0.22 | 0.4 |

| 20 | 3/4 | 0.3 | 0.52 |

| 25 | 1 | 0.55 | 1.06 |

| 32 | 1 1/4 | 0.86 | 1.32 |

| 40 | 1 1/2 | 1.26 | 2.2 |

| 50 | 2 | 1.65 | 3.37 |

| 65 | 2 1/2 | 3 | 4.81 |

| 80 | 3 | 4.25 | 7.25 |

| 100 | 4 | 7.8 | 12 |

What is Tolerance for Threaded Coupling and Cap?

We manufacture and inspect the threaded coupling and cap according to ASME B16.11. If they are in the tolerance, they will be delivered to qualified area.

| Nominal Diameter | Coupling Cap | Half-Coupling Boss | |

|---|---|---|---|

| End to End | End to End | ||

| DN | NPS | E F | E/2 |

| 6-8 | 1/8-1/4 | ±0.7 | ±0.4 |

| 10-20 | 3/8-3/4 | ±1.5 | ±0.8 |

| 25-50 | 1-2 | ±2 | ±1 |

| 65-100 | 2 1/2-4 | ±2.5 | ±1.3 |

Package of 316 Stainless Steel Coupling

We marked all Stainless Steel Pipe Couplings with Grade, Lot No, Size, Standard and Pressure. Our workers sleeved 316 Stainless Steel Threaded Couplings into plastic bag individually, wrapped them with water-proof material, bundled packages with nylon rope.

Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. great care is taken during operation and transportation.

316 Stainless Steel Threaded Coupling

Inspection of A182 F316 Threaded Coupling

- Visual the surface of threaded coupling body. Such as dents, die marks, porosity, undercuts.

- Check the marking. Size, ASTM Material Code & Grade, Pressure, Heat No.

- Measure dimensions. Such as diameter, wall thickness, and length of the thread.

- Test thread of threaded coupling with go/no go gauge.

BSP Threads

How to Manufacture BSPP Threaded Coupling?

Drawing & Specification for SS 316 Threaded Coupling

Threaded Coupling Drawing

| Nominal Size | End-to-End | Outside Diameter | Length of Thread | |||

| NPS | DN | W | D | L 5 min | L 2 min | |

| 3000 & 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1 1/4 | 67 | 57 | 64 | 17 | 18 |

| 40 | 1 1/2 | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19 | 19.2 |

| 65 | 2 1/2 | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 |

Socket Weld Reducing Tee

1 x 1 x 1/2 Socket Weld Reducing Tee Class 6000 ASTM A182 F316 ASME B16.11

USD21 USD20

Stainless Steel Hex Nipple

1/2 inch Sch80 NPT Hex Nipple Stainless Steel 304 ASME B16.11

USD3 USD2.5

45 Degree Long Radius Elbow

6” STD 45 Degree Long Radius Elbow Seamless ASTM A420 WPL6 ASME B16.9

USD8 USD7

8 Inch Pipe Cap A403 WP304

8 Inch Steel Pipe Cap Sch40S Seamless BW ASTM A403 WP304 ASME B16.9

USD37 USD36