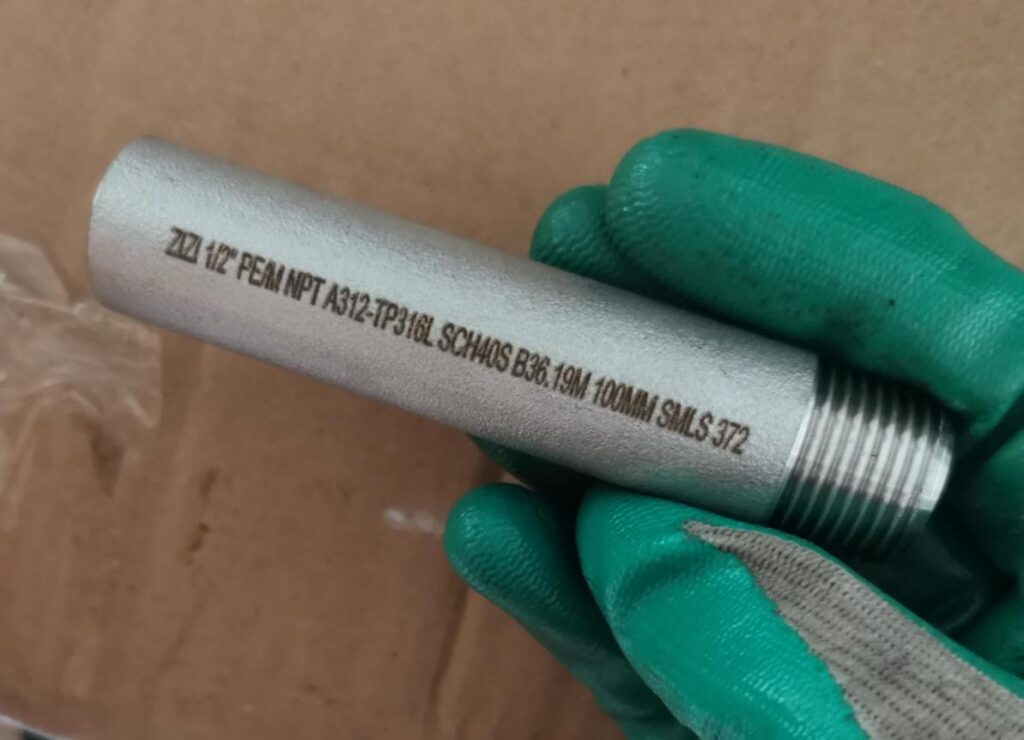

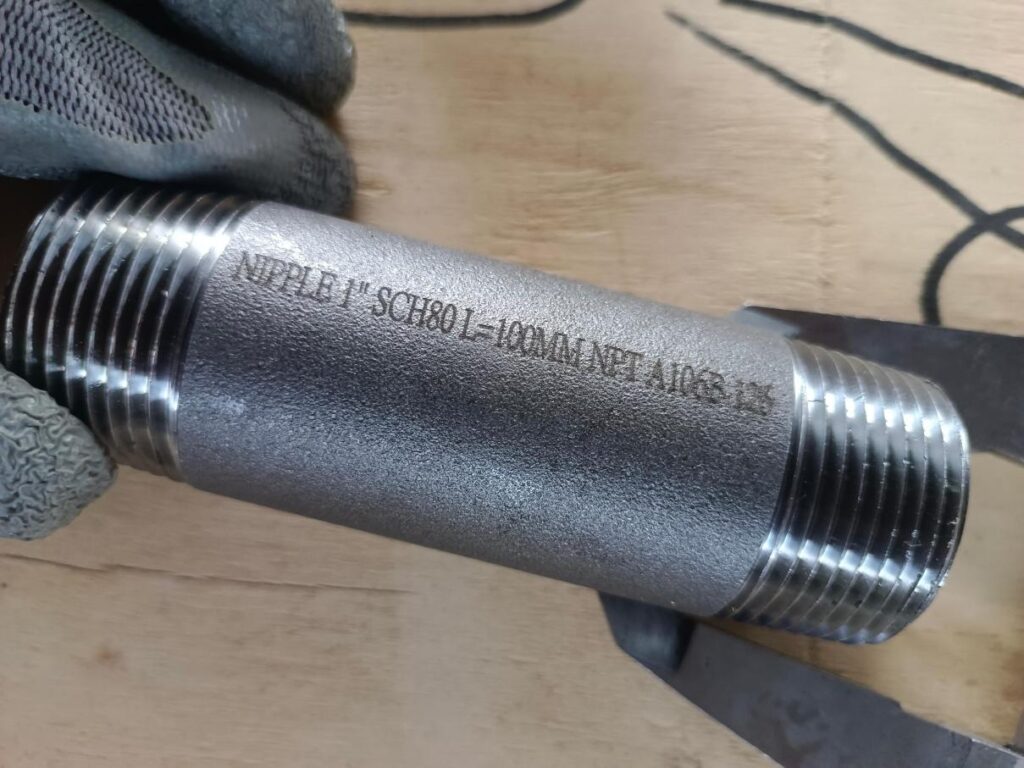

NPT threaded pipe nipple is a short tubular pipe fittings, mainly used to connect pipes, valves, equipment and other components. It is usually made of metal materials, such as carbon steel, stainless steel, etc. , to meet different engineering needs.

Specification of ASTM A733 Pipe Nipple Fittings

| Diameter | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Thickness | STD, SCH 40, SCH 80, SCH 160, XXS |

| End Type | TBE, TOE, Male, Female |

| Thread Type | NPT, BSPP, BSPT, PF, PT |

| Surface | Anti-rust Oil, Galvanized or PE Coated. |

| Carbon Steel | ASTM A105, A694 F52, F60, F65, F70, A350 LF2, LF3 |

| Alloy Steel: | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

| Stainless Steel: | ASTM A182 F304/304L, F304H, F316/316L, F310, F317, F321 |

| Duplex Steel: | ASTM A182 F51, F53, F55, F60 |

Threaded Pipe Nipple Dimensions

NPT threaded pipe nipple fittings are a short piece of pipe with external threaded end. It is commonly used in small diameter pipeline within 12 inch to connect pipes.

| Nominal Size | OD of Pipes | Lengths of Thread | Wall of pipes | Pipe Nipple Lengths | |||

| DN | NPS | OD | L 2 min | T | L | ||

| Ⅰ | Ⅱ | Ⅲ | |||||

| 6 | 1/8 | 10.3 | 6.7 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 8 | 1/4 | 13.7 | 10.2 | ||||

| 10 | 3/8 | 17.1 | 10.4 | ||||

| 15 | 1/2 | 21.3 | 13.6 | STD,XS Sch40,Sch80 | 50 | 75 | 100 |

| 50 | 3/4 | 26.7 | 13.9 | ||||

| 25 | 1 | 33.4 | 17.3 | ||||

| 32 | 11/4 | 42.2 | 18.0 | STD,XS Sch40,Sch80 | 75 | 100 | 150 |

| 40 | 11/2 | 48.3 | 18.4 | ||||

| 50 | 2 | 60.3 | 19.2 | ||||

| 65 | 21/2 | 73.0 | 28.9 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 80 | 3 | 88.9 | 30.5 | ||||

| 90 | 31/2 | 101.6 | 31.8 | ||||

| 100 | 4 | 114.3 | 33.0 | STD,XS Sch40,Sch80 | 100 | 150 | 200 |

| 125 | 5 | 141.3 | 35.7 | ||||

| 150 | 6 | 168.3 | 38.4 | ||||

| 200 | 8 | 219.1 | 43.5 | STD,XS Sch40,Sch80 | 150 | 200 | 250 |

| 250 | 10 | 273.0 | 48.9 | ||||

| 300 | 12 | 323.8 | 54.0 | ||||

What are the Types of Pipe Nipple Ends

1, PE X PE.

2, PE X BE.

3, PE X THD

4, BE X BE

5, BE X THD

6, THD X THD

PE means plain end, BE means beveling end, and THD means threaded end.

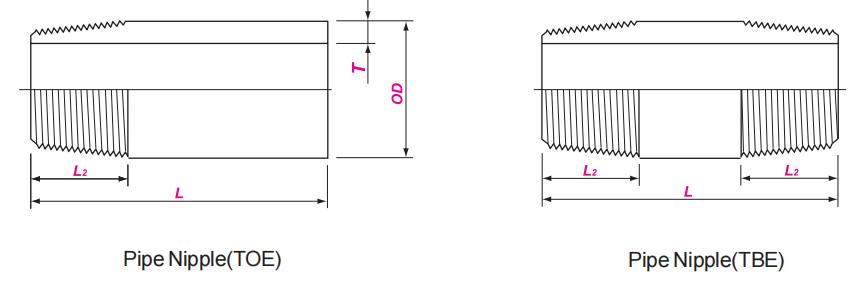

TOE Threaded Nipple

TOE ASTM A733 pipe nipple fittings are threaded only on one end, and the other end is plain or bevel. This structure makes it have specific connection uses in pipeline systems.

TBE Threaded Nipple

TBE threaded nipple has threads at both ends, which can connect pipes or pipe fittings that need to be threaded at both ends. This makes it more flexible in pipeline connection. TBE ASTM A733 pipe nipple fittings can be used directly to connect two pipes with external threads, or to connect a pipe with external threads and a device or pipe fitting with internal threads.

How to Inspect Threaded Pipe Nipple

For the inspection of NPT threaded pipe nipple fittings. First use a vernier caliper or digital caliper to directly measure the length of the threaded nipple. Then perform pipe diameter and wall thickness inspection.

Measuring pipe diameter with an outside micrometer. For the outside diameter of the external pipe nipple, use an outside micrometer to measure.

Ultrasonic thickness gauge measures wall thickness. Ultrasonic thickness gauge measures the wall thickness of threaded nipple by emitting and receiving ultrasonic signals.

Packaging of Pipe Nipple Fittings

●NPT threaded pipe nipple fittings should be specially protected during packaging to avoid contact with sharp objects and prevent scratches or bumps. Therefore, we use plastic pipe caps to protect the threaded ports.

●Plastic film is one of the commonly used materials for NPT threaded pipe nipple fittings packaging. It has good flexibility and moisture resistance.

●We will use high-strength, compression-resistant, and tear-resistant cartons to ensure that the cartons can withstand the weight of the threaded nipples and the impact during transportation.