What is MSS SP-83 Specification

ZIZI ENGEERING CO LTD is professional and experience in servicing and producing all types of pipe fittings. MSS SP-83 Union is one of the main products of ZIZI ENGERING CO LTD.

MSS SP 83 is the specification for socket weld and threaded union which cover size tolerance, marking, material etc.

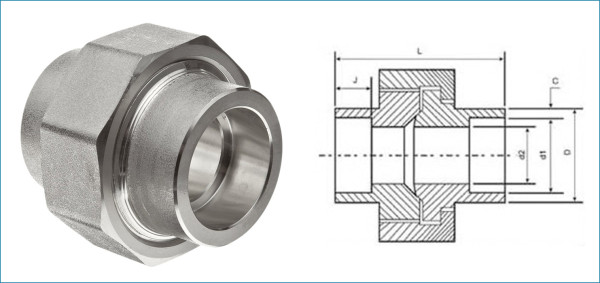

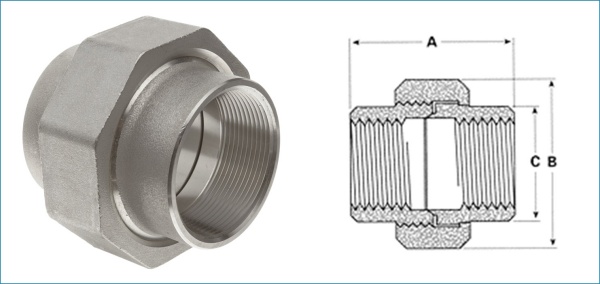

MSS SP-83 union is an active pipe connection fitting with the feature of easy for assemble and disassemble. It can be widely used in different diameters pipeline connection, and the connection of meter and valve with pipe line. Generally, a complete union shall consist of three parts: male end, female end, and nut. The two ends connect two pipes and the nut connects the two ends like a coupling. It is forged with round steel or ingot and then lathed into shape. It connects pipes by threads and includes internal thread type and external thread type.

We Can Supplied MSS SP-83 Union scope

| Size | 1/8″ to 3″ ( DN6 to DN80) |

| Pressure Rating | Class 3000 |

| Standard | MSS SP-83 |

| Type | Socket Weld Union and Threaded Union |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L/F51/F55 |

ASTM A105 Carbon Steel Union

ASTM A105 union is forged fittings made of carbon steel material, generally produced according to the MSS SP-83 standard. ASTM A105 Union is widely used in various pipeline systems due to their superior performance and low cost.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

ASTM A105 Union have been widely used in pipeline systems due to their high strength, excellent sealing performance. MSS SP-83 Union can providing important guarantees for the safe and stable operation of pipeline systems.

ASTM A182 MSS SP-83 Union

ASTM A182 forged pipe fittings refer to pipe fittings forged from alloy, stainless steel, or duplex steel materials. These material typically have excellent corrosion resistance, good mechanical properties to ensure the safe, and operation of pipeline.

Alloy Steel Material Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A182 F5 | MIN | 0.30 | 4.00 | 0.44 | |||||

| MAX | 0.15 | 0.60 | 0.030 | 0.030 | 0.50 | 0.50 | 6.00 | 0.65 | |

| ASTM A182 F9 | MIN | 0.30 | 0.50 | 8.00 | 0.90 | ||||

| MAX | 0.15 | 0.60 | 0.030 | 0.030 | 1.00 | 10.00 | 1.10 |

Alloy Steel Material Mechanical Properties

| MATERIAL | ASTM A182 F5 | ASTM A182 F9 |

| T.S (MPA) | 485 min | 585 min |

| Y.S (MPA) | 275 min | 380 min |

| EL % | 20 min | 20 min |

| R/A % | 35 min | 40 min |

| HARDNESS | 143-217 | 179-217 |

Stainless Steel Material Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 |

Stainless Steel Material Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min |

| EL % | 30 min | 30 min | 35 min | 35 min |

| R/A % | 50 min | 50 min | 50 min | 45 min |

MSS SP-83 Union should be paid to their quality and performance to ensure the safety, and efficiency of fluid transportation.

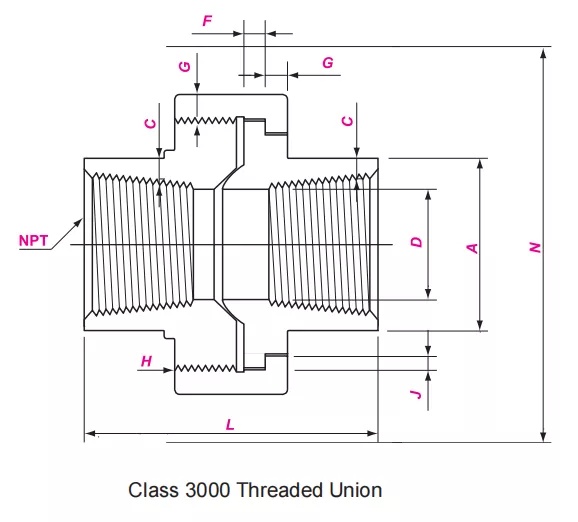

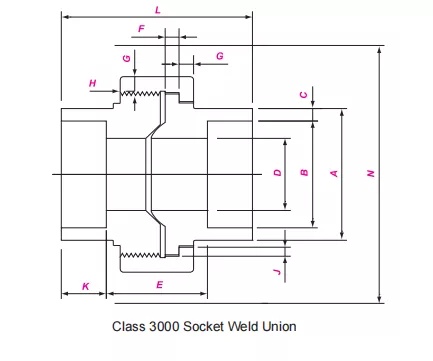

MSS SP-83 Union Dimension and Weight

Class 3000 Threaded Union Dimension

| Nominal Size | Pipe End | Wall | Bone | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem Nut | |

| DN | NPS | A min | C min | D | F min | G min | H | J min | L nom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 6.4 | ||||||||||

| 8 | 1/4 | 19.1 | 3 | 11.1 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 9.4 | ||||||||||

| 10 | 3/8 | 22.9 | 3.2 | 14.3 | 3.4 | 3.4 | 14 | 1.4 | 46 | 56 |

| 13.5 | ||||||||||

| 15 | 3/4 | 27.7 | 3.7 | 17.9 | 3.7 | 3.7 | 14 | 1.5 | 49 | 59 |

| 17.1 | ||||||||||

| 20 | 1/2 | 33.5 | 3.9 | 23 | 4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 21.4 | ||||||||||

| 25 | 1 | 41.4 | 4.5 | 29 | 4.6 | 4.4 | 11 | 1.9 | 62 | 79 |

| 27.7 | ||||||||||

| 32 | 1-1/4 | 50.5 | 4.9 | 37.7 | 5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 35.4 | ||||||||||

| 40 | 1-1/2 | 57.2 | 5.1 | 43.5 | 5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 41.2 | ||||||||||

| 50 | 2 | 70.1 | 5.5 | 55.6 | 6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 52.1 | ||||||||||

| 65 | 2-1/2 | 85.3 | 7 | 66.3 | 7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 64.3 | ||||||||||

| 80 | 3 | 102.4 | 7.6 | 82.6 | 8.3 | 8 | 8 | 3.5 | 109 | 176 |

| 77.3 | ||||||||||

Class 3000 Socket Weld Union Dimension

| DN | NPS | A | B | C | D | E | F | G | H | J | K | L | N |

| 6 | 1/8 | 21.8 | 10.9 | 3.2 | 6.1 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 8 | 1/4 | 21.8 | 14.3 | 3.3 | 8.5 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 10 | 3/8 | 25.9 | 17.7 | 3.5 | 11.8 | 23.8 | 3.4 | 3.4 | 14 | 1.4 | 9.7 | 46 | 56 |

| 15 | 3/4 | 31.2 | 21.9 | 4.1 | 15 | 23.8 | 3.7 | 3.7 | 14 | 1.5 | 9.7 | 49 | 59 |

| 20 | 1/2 | 37.1 | 27.3 | 4.3 | 20.2 | 28.6 | 4.1 | 4.1 | 11 | 1.7 | 12.7 | 56.9 | 66 |

| 25 | 1 | 45.5 | 34 | 5 | 25.9 | 30.2 | 4.6 | 4.4 | 11 | 1.9 | 12.7 | 62 | 79 |

| 32 | 1-1/4 | 54.9 | 42.8 | 5.3 | 34.3 | 36.6 | 5.3 | 5.2 | 10 | 2.1 | 12.7 | 71.1 | 94 |

| 40 | 1-1/2 | 61.5 | 48.9 | 5.5 | 40.1 | 38.1 | 5.8 | 5.6 | 10 | 2.3 | 12.7 | 76.5 | 112 |

| 50 | 2 | 75.2 | 61.2 | 6 | 51.7 | 41.4 | 6.6 | 6.4 | 10 | 2.7 | 15.7 | 86.1 | 132 |

| 65 | 2-1/2 | 91.7 | 73.9 | 7.7 | 61.2 | 56.9 | 7.5 | 7.1 | 8 | 3.1 | 15.7 | 102.4 | 150 |

| 80 | 3 | 109.2 | 89.9 | 8.3 | 76.4 | 58.7 | 8.3 | 8 | 8 | 3.5 | 15.7 | 109 | 176 |

Weight List of MSS SP-83 Union

| NOMINAL SZIE | WEIGHT | |

| DN | NPS | 3000 |

| 6 | 1/8 | 0.25 |

| 8 | 1/4 | 0.3 |

| 10 | 3/8 | 0.35 |

| 15 | 3/4 | 0.46 |

| 20 | 1/2 | 0.61 |

| 25 | 1 | 0.85 |

| 32 | 1-1/4 | 1.35 |

| 40 | 1-1/2 | 2.85 |

| 50 | 2 | 4 |

| 65 | 2-1/2 | 4.9 |

| 80 | 3 | 7.1 |

Why Choose Us for MSS SP-83 Union

ISO and CE certified quality

Short delivery

Safe package

Reasonable price

One stop service

Full specification