Carbon steel seamless pipe is a hollow cross-section and no welds around it. It‘s made of carbon steel and processed perforation, hot rolling, or cold rolling to form seamless steel pipes. It have strong pressure bearing capacity, stable quality, good corrosion resistance, and strong mechanical properties. Their main materials include ASMT A106 GR B, API 5L GR B, ASTM A53 GR B, ASTM A333 GR6, etc. Carbon steel seamless pipe is widely used in petroleum, chemical, shipbuilding, nuclear power and machinery manufacturing.

Carbon steel seamless pipe is widely used, so ensuring the quality has always been a concern for customers. To ensure that their quality and performance meet usage requirements, a series of experiments and inspections are required. Today we will introduce some common methods for testing carbon steel seamless pipes.

Chemical Composition Analysis

Analyze the chemical composition of seamless carbon steel pipe through chemical analysis and instrumental analysis methods (such as infrared C-S analyzer, PMI,etc.) to determine whether the content of each element meets relevant standards.

ASTM A106 GR B Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V |

| ASTM A106 GR B | MIN | 0.29 | 0.10 | ||||||||

| MAX | 0.30 | 1.06 | 0.035 | 0.035 | 0.40 | 0.15 | 0.40 | 0.40 | 0.08 |

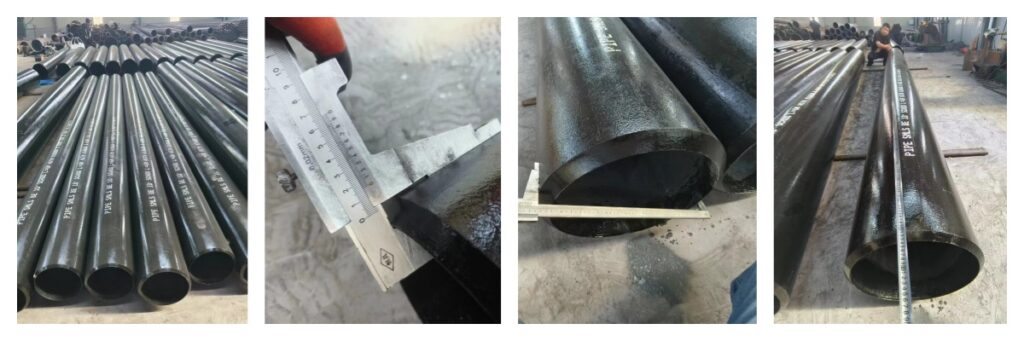

Inspect of Carbon Steel Seamless Pipe Dimension and Shape

Steel pipe wall thickness inspection. Use micrometers and ultrasonic thickness gauges to measure the wall thickness both ends of the steel pipe.

Inspection of outer diameter and ovality of steel pipes. Using calipers, vernier calipers or ring gauges, measure the max and min points to evaluate their outer diameter and ovality.

Carbon Steel Seamless pipe length inspection. Steel tape measure, manual or automatic length measuring equipment are used to check the length of the steel pipe.

On site inspection of carbon steel seamless pipe

Surface Quality Inspection

Artificial visual inspection: Under appropriate lighting conditions, inspect the surface quality of steel pipes through standards, experience, and identification.

Non Destructive Testing

Ultrasonic testing (UT). Used to detect various defects inside and on the surface of steel pipes, such as cracks, pores, etc.

Radiographic testing. Using radiation to penetrate steel pipes to detect internal defects such as capillary holes, cracks, etc.

Properties Inspection of Carbon Steel Seamless Pipe

Tensile test. Measures the stress and deformation of steel pipes during the tensile process to evaluate their strength and plasticity indicators.

Impact test: Passed through CVN, notch C-type V-shaped and other methods are used to evaluate the impact toughness.

Hardness test: Use methods Brinell (HB), Rockwell (HRC), and Vickers (HV) to measure the hardness value of steel pipes.

Mechanical Properties Between ASTM A53 GR B and ASTM A106 GR B

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A53 GR B | 415 min | 240 min | 30 min |

| ASTM A106 GR B | 415 min | 240 min | 22 min |

Process performance inspection of Carbon Steel Seamless Pipe

Flattening test: The steel pipe is flattened by a specific pressure to evaluate its plastic deformation ability.

Ring tensile test: To test the tensile performance of steel pipes through circular stretching.

Expansion and curling test: Evaluate the deformation ability of steel pipes by simulating expansion and curling processes in actual use.

Bending test: Evaluate the bending performance and crack resistance of steel pipes by bending them.

Other specialized tests

Corrosion resistance testing: Through simulated environmental experiments, test the corrosion resistance of steel pipes to different corrosive media.

Pressure performance testing: Conduct a water pressure test on seamless steel pipes to test their pressure resistance.