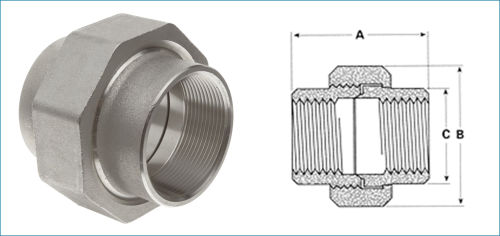

Stainless steel threaded union is a pipe fitting that is connected in a threaded form and is the most common type of pipe fitting in industry. Threaded union make pipeline connections simpler and easier to disassemble and replace, saving the cost of pipeline connections. It’s production according to the American standard MSS SP-83, which makes the stainless steel threaded joint convenient and reliable when connecting pipelines.

Specification of Stainless Steel Threaded Union

| Thread type | NPT/PT/BSPP/BSPT/PF |

| Size range | 1/8″-3″ / DN6-DN80 |

| Pressure | Class3000 |

| Standard | MSS SP-83 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Application | Oil and Gas /Pipeline/Power Industries/Chemical Industries |

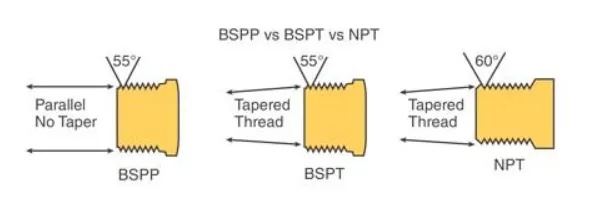

MSS SP-83 threaded union typically use threaded connections. Thread specifications may include various types such as BSP (British Standard Pipe Thread), NPT (American Standard Cone Pipe Thread), etc.

ASTM A182 Stainless Steel Threaded Union

ASTM A182 is a material standard that covers various grades of alloy steel and stainless steel. Common stainless steel materials, such as F304/L, F316/L, etc., are suitable for manufacturing threaded union. Stainless steel threaded union connect pipes through threads, making the connection and disassembly of pipes easier and with high pressure resistance.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | ||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 30 min | 30 min |

| R/A % | 50 min | 50 min |

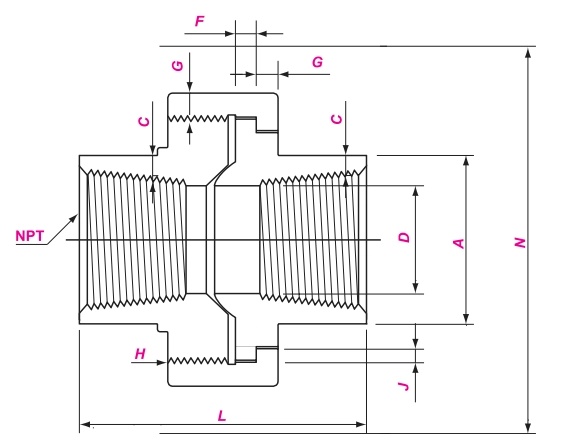

Dimension of MSS SP-83 Threaded Union

MSS SP-83 standard involve multiple aspects, including outer diameter, inner diameter, thread size, wall thickness, etc., and these parameters may vary depending on specific specifications and models.

| DN | NPS | Amin | Cmin | D | Fmin | Gmin | H | Jmin | Lnom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 6.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 8 | 1/4 | 19.1 | 3.0 | 11.1 9.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 10 | 3/8 | 22.9 | 3.2 | 14.3 13.5 | 3.4 | 3.4 | 14 | 1.4 | 46.0 | 56 |

| 15 | 1/2 | 27.7 | 3.7 | 17.9 17.1 | 3.7 | 3.7 | 14 | 1.5 | 49.0 | 59 |

| 20 | 3/4 | 33.5 | 3.9 | 23.0 21.4 | 4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 25 | 1 | 41.4 | 4.5 | 29.0 27.7 | 4.6 | 4.4 | 11 | 1.9 | 62.0 | 79 |

| 32 | 1¼ | 50.5 | 4.9 | 37.7 35.4 | 5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 40 | 1½ | 57.2 | 5.1 | 43.5 41.2 | 5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 50 | 2 | 70.1 | 5.5 | 55.6 52.1 | 6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 65 | 2½ | 85.3 | 7.0 | 66.3 64.3 | 7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 80 | 3 | 102.4 | 7.6 | 82.6 77.3 | 8.3 | 8.0 | 8 | 3.5 | 109.0 | 176 |

Weight List (KG)

| Nominal size | Union | |

| DN | NPS | 3000 |

| 6 | 1/8 | 0.25 |

| 8 | 1/4 | 0.30 |

| 10 | 3/8 | 0.35 |

| 15 | 1/2 | 0.46 |

| 20 | 3/4 | 0.61 |

| 25 | 1 | 0.85 |

| 32 | 1¼ | 1.35 |

| 40 | 1½ | 1.92 |

| 50 | 2 | 2.85 |

| 65 | 2½ | 4.90 |

| 80 | 3 | 7.10 |

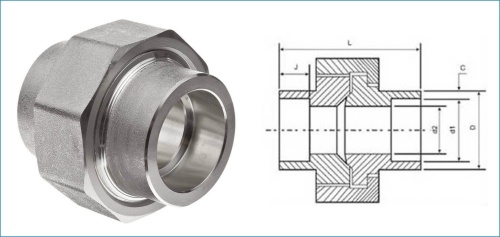

Difference Between Threaded Union and Socket Weld Union

Stainless Steel Threaded Union

Application: Due to its easy installation and disassembly, it is particularly suitable for scenarios that require frequent maintenance and replacement of pipeline connectors.

Connection method: Connect pipes through threaded connections. This connection method does not require welding and is easy and fast to operate.

Stainless Steel Socket Weld Union

Application: It is more suitable for scenarios with high requirements for connection strength and sealing. Stainless steel butt welde union can meet these requirements and ensure the stable operation of pipeline systems.

Connection method: Use socket welding to connect the pipeline. During the connection process, it is necessary to insert the pipeline into the socket of the joint, and then use welding equipment to weld both ends of the joint to achieve a firm connection between the pipelines. This connection method has high connection strength and sealing, but the operation is relatively complex and requires professional skills.

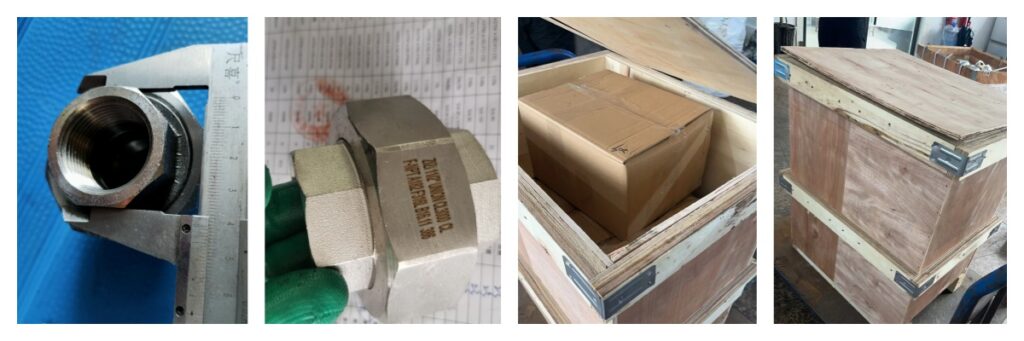

Inspection and Packaging

The size inspection of stainless steel threaded union involves multiple methods and steps, and it is necessary to select appropriate inspection methods and equipment according to the actual situation, and strictly follow the operating procedures for inspection to ensure the accuracy and reliability of the measurement results.

Application

Stainless steel threaded unions are highly favored due to their excellent performance and wide range of applications. They are widely used in pipeline connections and equipment connections in various industrial and civilian fields.

Civil Engineering

Plumbing

Automobile Manufacturing

Shipbuilding Industry

Metallurgical and Chemical Industry

Pharmaceutical and Food Machinery

Instruments and Apparatuses

Mechanical Equipment Connectors