Stainless steel threaded elbow is a pipe fitting that connects and changes the direction of the pipeline through threaded connection. As an important component of stainless steel threaded fittings, it has excellent corrosion resistance, mechanical strength, and sealing performance. Therefore, it is widely used in various fields such as industry, chemical industry, oil and gas, food, etc. In the selection and use process, it is necessary to fully consider factors such as pipeline diameter, elbow angle, material quality, usage environment, and working pressure to ensure the safe, reliable, and efficient operation of the pipeline system.

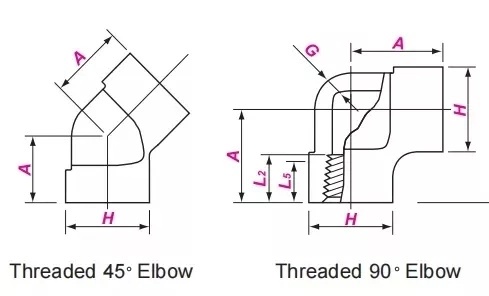

Stainless steel threaded elbow shape is usually 45 degrees, 90 degrees. The production of stainless steel threaded elbows also needs to follow international production standards, such as GB/T14383, ASME B16.11, etc., to ensure that the quality and performance of the products meet the requirements.

ASME B16.11 Stainless Steel Threaded Elbow

ASME B16.11 is a production standard for forged fittings, which includes fittings with socket and threaded connections. It specifies requirements for material, size, shape, pressure rating, tolerance range, etc. to ensure their safety and reliability in the industrial field. This standard covers various types of forged fittings, such as forged elbows, tees, couplings, caps, plugs,etc.

We are specialized in supplying stainless steel threaded elbow in three pressure ratings: class 2000,Class 3000 and 6000 at reasonable price in various sizes as per requirement.

Size: 1/8″ to 4″ / DN 6 to 100

Pressure: Class 2000, 3000, 6000

Thread Type: BSPP, BSPT, PT, NPT, MPT

Product: NPT Threaded Elbow, Tee, Coupling, Union, Bushing, Nipple, Plug.

Dimension

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||

| DN | NPS | A | H | Gmin | L 5 min | L 2 min | |||||

| 90°Elbows | 45°Elbows | ||||||||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 21 | 25 | 17 | 19 | 22 | 25 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 25 | 28 | 19 | 22 | 25 | 33 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 28 | 33 | 22 | 25 | 33 | 38 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 33 | 39 | 25 | 28 | 38 | 46 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 38 | 44 | 28 | 33 | 46 | 56 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 44 | 51 | 33 | 35 | 56 | 62 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 11/4 | 51 | 60 | 35 | 43 | 62 | 75 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 11/2 | 60 | 64 | 43 | 44 | 75 | 84 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 64 | 83 | 44 | 52 | 84 | 102 | 7.14 | 12.09 | 19 | 19.2 |

| 65 | 21/2 | 83 | 95 | 52 | 64 | 102 | 121 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3 | 95 | 106 | 64 | 79 | 121 | 146 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 114 | 114 | 79 | 79 | 152 | 152 | 11.18 | 18.67 | 27.7 | 33 |

Weight List of Stainless Steel Threaded Elbow

| NOMINAL SIZE | 90 DEGREE THREADED ELBOW | 45 DEGREE THREADED ELBOW | |||||

| DN | NPS | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.08 | 0.10 | 0.18 | 0.08 | 0.08 | 0.14 |

| 8 | 1/4 | 0.08 | 0.15 | 0.33 | 0.08 | 0.12 | 0.27 |

| 10 | 3/8 | 0.13 | 0.30 | 0.48 | 0.11 | 0.26 | 0.49 |

| 15 | 1/2 | 0.22 | 0.45 | 0.72 | 0.23 | 0.42 | 0.69 |

| 20 | 3/4 | 0.32 | 0.70 | 1.29 | 0.29 | 0.59 | 1.12 |

| 25 | 1 | 0.50 | 1.21 | 1.65 | 0.43 | 0.96 | 1.47 |

| 32 | 1-1/4 | 0.80 | 1.47 | 2.70 | 0.67 | 1.15 | 2.65 |

| 40 | 1-1/2 | 0.93 | 2.60 | 3.90 | 0.82 | 2.02 | 3.60 |

| 50 | 2 | 1.60 | 3.05 | 6.05 | 1.32 | 2.50 | 4.60 |

| 65 | 2-1/2 | 2.95 | 5.80 | 9.88 | 3.30 | 3.81 | 7.81 |

| 80 | 3 | 5.6 | 8.85 | 16.4 | 5.4 | 6.3 | 13.1 |

| 100 | 4 | 10.5 | 14.9 | 23.5 | 9.00 | 9.80 | 17.0 |

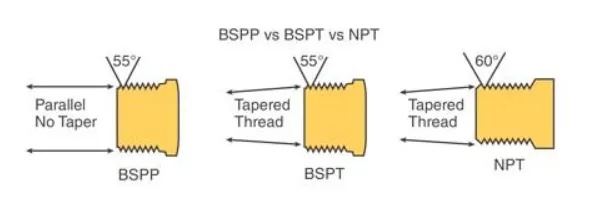

Common Thread Types of Threaded Elbow

BSPP: British Standard Pipe Parallel

BSPT: British Standard Pipe Tapered

NPT: American National Standard Pipe Tpaer

ASTM A182 Stainless Steel Threaded Elbow

Stainless steel threaded elbows are mainly made of stainless steel materials such as 304, 316L, etc. These materials have good corrosion resistance and mechanical properties, and can adapt to various harsh environments.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316 | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | 0.01 | |

| ASTM A182 F316L | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 15.00 | 18.00 | 3.00 | 0.01 |

Mechanical Properties

| MATERIAL | ASTM A182 F316 | ASTM A182 F316L |

| T.S (MPA) | 515 min | 485 min |

| Y.S (MPA) | 205 min | 170 min |

| EL % | 30 min | 30 min |

| R/A % | 50 min | 50 min |

How to Inspect Stainless Steel Threaded Elbow

Visual the surface of threaded elbow body.

Measure dimensions that large end diameter, small end diameter, wall thickness of outlets.

Check the marking of 1-1/4″ Class 6000 ASTM A182 F304 ASME B16.11 2100

Application

Pipeline System

Petroleum and Chemical Industry

Fire Protection System

Chemical Industry

Food Processing Industry