Stainless steel threaded outlet commonly used connect pipeline systems and are an important type of stainless steel threaded fittings.

The manufacturing process of stainless steel threaded outlet mainly includes forging, heat treatment, machining and other steps. The forging process can ensure that the outlet has good mechanical properties and corrosion resistance.

Types of MSS SP-97 Outlet

MSS SP-97 is the production standard for American forged outlet. The MSS SP-97 standard also specifies the end types of export fittings, which should comply with the requirements of ASME B16.25 (butt welded ends) or ASME B16.11 (socket welded and threaded ends).

There are various types of stainless steel outlet, including butt welded outlet, threaded outlet, socket weld outlet, nipple outlet, elbow outlet, flange outlet, etc. The common outlet in the market include butt welded outlet, threaded outlet, and socket weld outlet. Different types of outlet have their own unique characteristics and applicability to meet the needs of different pipeline systems.

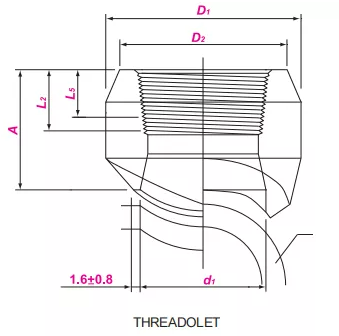

Dimension

The size range of conventional threaded outlet is between 1/8 inch and 4 inches, with common pressure ratings including 3000LBS and 6000LBS .

| DN | NPS | DN | NPS | A | D1 | D2 | L | d1 | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 19 | – | 27 | – | 22 | – | 6.7 | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 19 | – | 27 | – | 22 | – | 10.2 | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 21 | – | 30 | – | 25 | – | 10.4 | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 25 | 32 | 38 | 45 | 33 | 42 | 13.6 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 27 | 37 | 47 | 52 | 39 | 48 | 13.9 | 30 | 25 |

| 32~900 | 11/4~36 | 25 | 1 | 33 | 40 | 56 | 63 | 48 | 58 | 17.3 | 36 | 33 |

| 40~900 | 11/2~36 | 32 | 11/4 | 33 | 41 | 66 | 72 | 58 | 67 | 18.0 | 45 | 38 |

| 50~900 | 2~36 | 40 | 11/2 | 35 | 43 | 75 | 83 | 64 | 77 | 18.4 | 51 | 49 |

| 65~900 | 21/2~36 | 50 | 2 | 38 | 52 | 90 | 104 | 77 | 93 | 19.2 | 65 | 59 |

| 80~900 | 3~36 | 65 | 21/2 | 46 | – | 105 | – | 94 | – | 28.9 | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 51 | – | 124 | – | 114 | – | 30.5 | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 57 | – | 154 | – | 140 | – | 33.0 | 121 | – |

Weight List of Stainless Steel Threaded Outlet

| Branch Nomina Size | THRD Outlet | ||

| DN | NPS | 3000 | 6000 |

| 6 | 1/8 | 0.05 | |

| 8 | 1/4 | 0.05 | |

| 10 | 3/8 | 0.09 | |

| 15 | 1/2 | 0.17 | 0.32 |

| 20 | 3/4 | 0.22 | 0.47 |

| 25 | 1 | 0.43 | 0.65 |

| 32 | 1-1/4 | 0.61 | 0.96 |

| 40 | 1-1/2 | 0.69 | 1.28 |

| 50 | 2 | 1.1 | 2.15 |

| 65 | 2-1/2 | 1.52 | |

| 80 | 3 | 2.50 | |

| 90 | 3-1/2 | ||

| 100 | 4 | 4.10 | |

ASTM A182 Stainless Steel Threaded Outlet

ASTM A182 is a set of standards published by the American Society for Testing and Materials (ASTM). It mainly used to standardize the material, manufacturing process, and performance requirements of forged or rolled alloy steel and stainless steel fittings, flanges, and other components for high temperature applications.

Stainless steel threaded outlet is made of stainless steel material that meets the ASTM A182 standard. Common stainless steel materials include ASTM A182 F304/F316/F44/F51/F53, etc.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

Installation and Maintenance

Installation: When installing stainless steel threaded outlet, it is necessary to follow the relevant installation specifications and standards. Then screw the branch socket into the thread of the main pipe and tighten it appropriately. Connect the branch pipe and check if the connection is tight and leak free.

Maintenance: Regularly check whether the connection of the stainless steel threaded outlet and promptly deal with it.

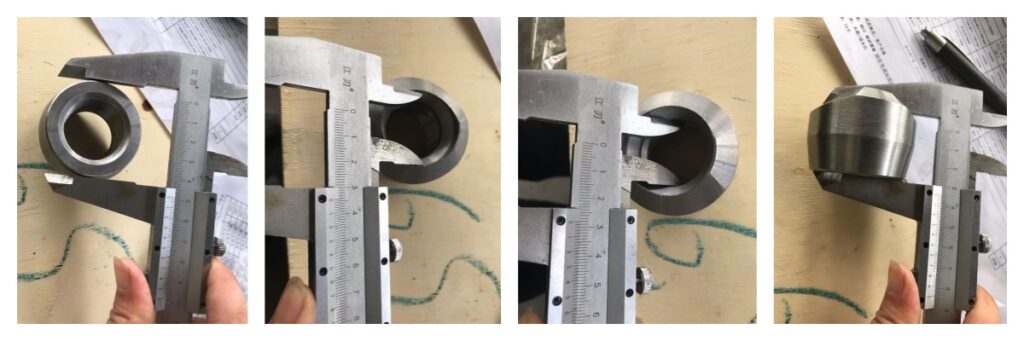

Quality Inspection

ZIZI ENGEERING CO LTD specializes in producing stainless steel socket weld outlet in accordance with the American standard MSS SP-97. We can supplied specifications ranging from 1/8 “to 4” and pressures of Class 3000 and 6000.

Visual the surface of socket weld fittings body.

Measure dimensions that large end diameter, small end diameter, wall thickness of outlets.

Check the marking of 2″ x 1″ Class 3000 ASTM A182 F304 MSS SP-97 ZZ218

Application of Stainless Steel Threaded Outlet

Stainless steel threaded outlet, as a key pipeline connection component, have sufficient strength and corrosion resistance, as well as meet specific quality requirements.

Therefore, they are widely used in industries such as pressure vessels, pipeline systems, oil and gas, chemical, nuclear energy, power, and aerospace.