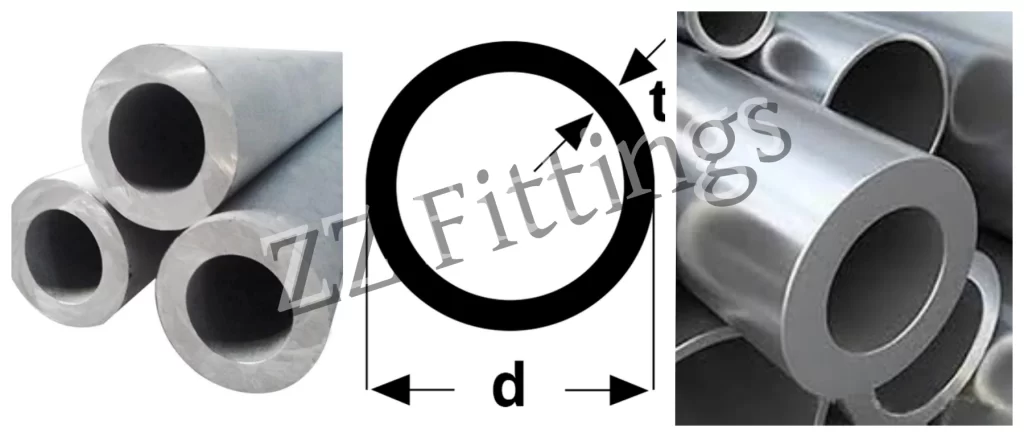

Heavy thick steel pipes produced by ZIZI Engineering are designed to handle the most extreme pressures and stresses. Making them indispensable in the petrochemical, chemical, and nuclear power industries. Our thick walled seamless pipes are classified according to the SCH120, SCH160, and XXS thick walled plan numbers to ensure that they meet the strict requirements of high-pressure environments.

Heavy thick steel pipes can be divided into seamless pipes and welded pipes according to different manufacturing processes.

These pipes are available in various schedules to cater to different levels of pressure, including SCH100, 120, 140, and 160. For even more demanding applications, we offer double extra strong (XXS) heavy wall seamless pipes.

Heavy Wall Pipes Specification

| Packing | Standard package, plastic caps, anti-rust oil, Beveled ends |

| Application | Oil and casing Pipe; Pressure Vessel Pipe; Hydralic Pillar used Pipe; Automobile Pipe; War industry Pipe |

| Outer Diameter Size in Inch | 3/4”To 48” Wall Thickness: SCH120, SCH160, and XXS |

| Standard | ASTM, JIS, DIN, GB, API, ANSI |

| Material | ASTM 106/A53 Grade B API5L Grade B X52 X42 X70 X6020G, 40MnB, 20MnVB, 50CrV, 27SiMn, 40Cr, 12CrNi3, 12Cr2Ni4, 25MnG, 30CrMnSi, 45Cr, 12Cr1MoV, 50Cr, 20Cr, 35CrMo, 20#, 42CrMo, 38CrMoAL, 20CrMnSi, 12CrNi2, 20G, 20CrMo, 20MnG, 20A, 38CrSi, 45#, 45Mn2, 35CrMnSi, 45CrNiMoVA, 30CrMnTi, 30Cr, 40CrNiMoA, 20CrMnTi, 40Mn2, 35#, 12CrMoG, 12CrMoV, 12CrMo, 35Cr |

| Quality | API 5L , ISO, DNV |

| Pipe Marking | All Pipe are marked as follows: Supplier or Manufacturer’s Name, Standard, Grade, OD, Thickness, Length, Heat Number |

Supplier of Heavy Thick Steel Pipes from China

Diameter & Weight of SCH 160 Heavy Thick Steel Pipes

The pipe Schedule describes the pipe wall thickness. In same size, the thickness in mm will be larger while pipe schedule number increases. It just affect the inside diameter only. Usually The double Extra Strong (XXS) wall is thicker than SCH 160 from 1/2″ to 6″, but SCH 160 is thicker than the XXS wall from 8″ to 12″.

| NPS | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| OD ( mm) | 21.3 | 26.7 | 33.4 | 42.2 | 48.3 | 60.3 | 73 | 88.9 | 114.3 | 141.3 | 168.3 | 21.9 | 273.1 | 323.9 | 355.6 | 406.4 | 457.2 | 508 | 558.8 | 609.6 |

| Thk (mm) | 4.78 | 5.56 | 6.35 | 6.35 | 7.14 | 8.74 | 9.53 | 11.1 | 13.5 | 15.9 | 18.3 | 23.0 | 28.58 | 33.32 | 35.71 | 40.49 | 45.24 | 50.01 | 53.98 | 59.54 |

| Weight (kg/m) | 1.95 | 2.9 | 4.24 | 5.61 | 7.3 | 11.1 | 14.9 | 21.4 | 33.5 | 49.1 | 67.6 | 111.3 | 172.3 | 238.8 | 281.7 | 365.4 | 459.4 | 564.8 | 672.2 | 808.2 |

SCH160 Seamless Pipes

Our Heavy thick seamless pipes are available in outer diameters ranging from 1/8 inches to 24 inches, with a wide variety of material grades and standards. Including ASTM A106 Grade B, ASTM A53 Grade B,ASTM A335,API5L Grade B and ASTM A312 stainless steel and more.

Schedule 160 heavy thick steel pipes is one such pipes that has a display of the properties of steel such as resistance to corrosion along with excellent strength. As the wall thickness and diameter of the pipes increases so does the schedule 160 pipes pressure rating. The increased thickness helps in increasing the pressure rating.

Characteristics of Seamless Pipes

No welded seams, reducing the risk of leaks and corrosion

Superior strength and pressure handling capabilities

Smooth internal and external surfaces, promoting better flow characteristics

Suitable for high-pressure, high-temperature, and corrosive environments

SCH160 Welded Pipes

Welded pipes are made by steel plate to the desired thickness, which is a manufacturing process that leaves seams on the pipe body. The next stage is to cut the joint into a diameter corresponding to the size of the pipeline to be constructed.

Resistance welding (ERW), spiral submerged arc welded pipe (SSAW), and straight seam submerged arc welded pipe are three different forms of welded steel pipes (LSAW). These three types of welded heavy thick steel pipes are manufactured in significantly different ways.

Characteristics of Welded Pipes

More economical compared to seamless pipes

Availability in large diameters and lengths

Suitable for low to moderate pressure applications

Potential for weld-related defects, requiring thorough inspection and quality control

Difference between Seamless and Welded Pipe

Electric Resistance Welded (ERW) pipes and seamless pipes are both widely used in various industries, but they differ significantly in their manufacturing processes.

The ERW process can produce pipes with relatively consistent wall thickness and accurate dimensions. However, the welded seam can be a weak point, making ERW pipes potentially less suitable for high-pressure applications compared to seamless pipes.

Seamless pipes can be manufactured using various methods, including hot rolling, cold drawing, or extrusion. The seamless manufacturing process allows for tighter tolerances, better surface finishes, and improved mechanical properties compared to ERW pipes.

the choice between ERW and seamless pipes depends on factors such as the application, pressure and temperature requirements, corrosion resistance, and cost considerations. While ERW pipes can be more cost-effective and suitable for certain applications, seamless pipes offer superior strength and performance in demanding environments.

Applications of heavy wall pipes

The increased strength, durability, and pressure handling capabilities of heavy thick steel pipes make them suitable for a wide range of applications across various industries.

Oil and Gas

Power Generation

Chemical and Petrochemical

Water Treatment and Distribution

Construction and Infrastructure

Automotive and Aerospace

Shipbuilding and Marine