Forged fittings standard including ASME B16.11, MSS-SP-79, MSS SP-83, MSS SP-95, MSS SP-97, and BS 3799 standards. They are used to build connection, between nominal bore schedule pipe and pipelines. They are supplied for extensive application range.

Forged fittings standard including typically available in two materials: Carbon steel and Stainless steel. Pressure rating: Class 2000,3000 and 6000 series.End connections of fittings are required to comply with pipe ends, either socket weld to plain end, or NPT to threaded end.

Forged pipe fittings require multiple processes, including material selection, forging, heat treatment, mechanical processing, and inspection. These fittings typically have high dimensional accuracy and surface quality, with a wide variety of fittings that can meet strict engineering requirements and usage environments.

How Many Types of Forged Fittings Standard

The production forged fittings standards include ASME B16.11; MSS SP-83; MSS SP-97; MSS SP-95, etc.

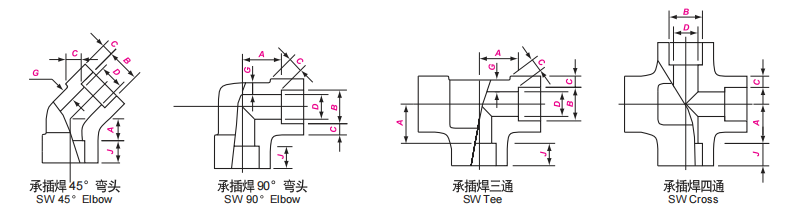

ASME B16.11 Types and Dimension

The ASME B16.11 standard is a production standard for forged high-pressure fittings published by the American Standards Institute. Specifically, the ASME B16.11 has detailed requirements for the material, size, shape, pressure rating, tolerance range, and other aspects of high-pressure forged fittings.

Socket Weld Fittings Data Sheet

| Nominal Size | Socket Bore Dia | Bore Dia.of Fitings | Socket Wall Thickness | Body Wal | Depth of Socket | Center to Bottom of Socket | |||||||||||||||

| D N | NPS | B | D | C | Gmin | J mim | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°Elbow Tee Cross | 45°Elbow | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 11.0 | 11.0 | 8 | 8 | ||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 11.0 | 13.5 | 8 | 8 | ||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 13.5 | 15.5 | 8.0 | 11.0 | ||||||

| 15 | 1/2 | 21.9 | 15.0 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 |

| 32 | 1-1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 |

| 40 | 1-1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 |

| 65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16.0 | 41.0 | 28.5 | ||||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | ||||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | ||||||||||||

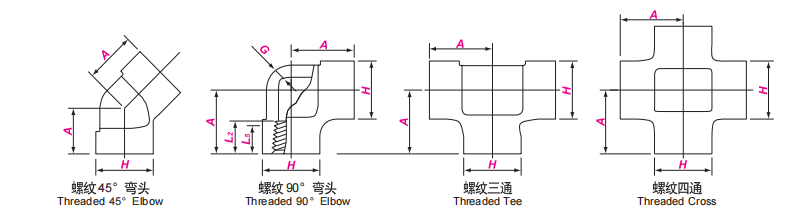

Threaded Fittings Data Sheet

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||||||

| DN | NPS | A | H | G min | min | mim | |||||||||

| 90 Ebows Tees Crosses | 45 Elbows | ||||||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

| 6 8 10 | 1/8 1/4 3/8 | 21 21 25 | 21 25 28 | 25 28 33 | 17 17 19 | 17 19 22 | 19 22 25 | 22 22 25 | 22 25 33 | 25 33 38 | 3.18 3.18 3.18 | 3.18 3.30 3.51 | 6.35 6.60 6.98 | 6.4 8.1 9.1 | 6.7 10.2 10.4 |

| 15 20 25 | 1/2 3/4 1 | 28 33 38 | 33 38 44 | 38 44 51 | 22 25 28 | 25 28 33 | 28 33 35 | 33 38 46 | 38 46 56 | 46 56 62 | 3.18 3.18 3.68 | 4.09 4.32 4.98 | 8.15 8.53 9.93 | 10.9 12.7 14.7 | 13.6 13.9 17.3 |

| 32 40 50 | 1-1/4 1-1/2 2 | 44 51 60 | 51 60 64 | 60 64 83 | 33 35 43 | 35 43 44 | 43 44 52 | 56 62 75 | 62 75 84 | 84 102 | 3.89 4.01 4.27 | 5.28 5.56 7.14 | 10.59 11.07 12.09 | 17.0 17.8 19.0 | 18.0 18.4 19.2 |

| 65 80 100 | 2-1/2 3 4 | 76 86 106 | 83 95 114 | 95 106 114 | 52 64 79 | 52 64 79 | 64 79 79 | 92 109 146 | 102 121 152 | 121 146 152 | 5.61 5.99 6.55 | 7.65 8.84 11.18 | 15.29 16.64 18.67 | 23.6 25.9 27.7 | 28.9 30.5 33.0 |

Class of The Forged Fittings VS Grade of the Connecting Pipes

| Joint Type | Class | Grade of Conneding Pipes | Joint Type | Class | Grade of Connecting Pipes |

| SW | 3000 | Sch80、XS | THRD | 2000 | Sch80、XS |

| 6000 | Sch160 | 3000 | Sch160 | ||

| 9000 | XXS | 6000 | XXS |

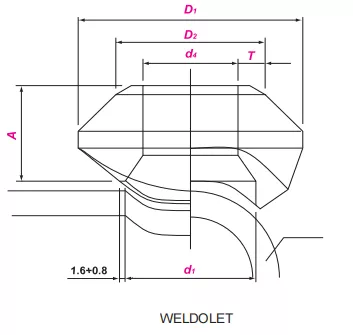

MSS SP-97 Types and Dimension

MSS SP-97 is a special forged fittings standard. This sdandard defines the requirements for integrally reinforced branch outlet fittings which includes weldolet, sockolet, threadolet and elbolet.

Weldolet Dimension

| Run pipe Nominal Size | Branch Nominal Size | Length | OD of Fitting | Cut hole Dia. | ||||||||

| A | D | d | ||||||||||

| DN | NPS | DN | NPS | STD | XS | SCH160 | STD | XS | SCH | STD | XS | SCH160 |

| 8~900 | 1/4~36 | 6 | 1/8 | 16 | 16 | – | 24 | 24 | – | 16 | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 16 | 16 | – | 26 | 16 | – | 16 | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 19 | 19 | – | 30 | 30 | – | 19 | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 19 | 19 | 28 | 36 | 36 | 36 | 24 | 24 | 14 |

| 25~900 | 1~36 | 20 | 3/4 | 22 | 22 | 32 | 43 | 43 | 46 | 30 | 30 | 19 |

| 32~900 | 11/4~36 | 25 | 1 | 27 | 27 | 38 | 55 | 55 | 51 | 36 | 36 | 25 |

| 40~900 | 11/2~36 | 32 | 11/4 | 32 | 32 | 44 | 66 | 66 | 63 | 45 | 45 | 33 |

| 50~900 | 2~36 | 40 | 11/2 | 33 | 33 | 51 | 74 | 74 | 71 | 51 | 51 | 38 |

| 65~900 | 21/2~36 | 50 | 2 | 38 | 38 | 55 | 90 | 90 | 82 | 65 | 65 | 43 |

| 80~900 | 3~36 | 65 | 21/2 | 41 | 41 | 62 | 104 | 104 | 98 | 76 | 76 | 54 |

| 90~900 | 31/2~36 | 80 | 3 | 44 | 44 | 73 | 124 | 124 | 122 | 93 | 93 | 73 |

| 100~900 | 4~36 | 90 | 31/2 | 48 | 48 | – | 138 | 138 | – | 113 | 113 | – |

| 125~900 | 5~36 | 100 | 4 | 51 | 51 | 84 | 154 | 154 | 154 | 120 | 120 | 98 |

| 150~900 | 6~36 | 125 | 5 | 57 | 57 | 94 | 187 | 187 | 188 | 141 | 141 | 122 |

| 200~900 | 8~36 | 150 | 6 | 60 | 78 | 105 | 213 | 227 | 222 | 170 | 170 | 146 |

| 250~900 | 10~36 | 200 | 8 | 70 | 99 | – | 265 | 292 | – | 220 | 220 | – |

| 300~900 | 12~36 | 250 | 10 | 78 | 94 | – | 323 | 325 | – | 275 | 265 | – |

| 350~900 | 14~36 | 300 | 12 | 86 | 103 | – | 379 | 381 | – | 325 | 317 | – |

| 400~900 | 16~36 | 350 | 14 | 89 | 10 | – | 411 | 416 | – | 257 | 361 | – |

| 450~900 | 18~36 | 400 | 16 | 94 | 106 | – | 465 | 468 | – | 408 | 403 | – |

| 500~900 | 20~36 | 450 | 18 | 97 | 111 | – | 522 | 525 | – | 459 | 455 | – |

| 550~900 | 22~36 | 500 | 20 | 102 | 119 | – | 573 | 584 | – | 508 | 509 | – |

| 650~900 | 26~36 | 600 | 24 | 116 | 140 | – | 690 | 708 | – | 614 | 612 | – |

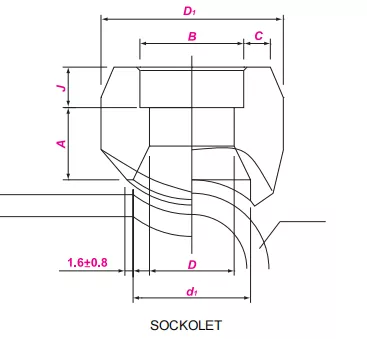

Socketolet Dimension

| DN | NPS | DN | NPS | J | A | D | C | d1 | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 9.5 | 10 | – | 27 | – | 3.18 | – | 16 | – |

| -10~900 | 3/8~36 | 8 | 1/4 | 9.5 | 10 | – | 27 | – | 3.78 | – | 16 | – |

| 18~900 | 1/2~36 | 10 | 3/8 | 9.5 | 13 | – | 30 | – | 4.01 | – | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 9.5 | 16 | 24 | 38 | 47 | 4.67 | 5.97 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 12.5 | 16 | 25 | 47 | 53 | 4.90 | 6.96 | 30 | 25 |

| 32~900 | 11/4~36 | 25 | 1 | 12.5 | 22 | 29 | 56 | 63 | 5.69 | 7.92 | 36 | 33 |

| 40~900 | 11/2~36 | 32 | 11/4 | 12.5 | 22 | 30 | 66 | 74 | 6.07 | 7.92 | 45 | 38 |

| 50~900 | 2 | 40 | 11/2 | 12.5 | 24 | 32 | 75 | 83 | 6.35 | 8.92 | 51 | 49 |

| 65~900 | 21/2~36 | 50 | 2 | 16 | 24 | 37 | 90 | 104 | 6.93 | 10.92 | 65 | 59 |

| 80~900 | 3~36 | 65 | 21/2 | 16 | 25 | – | 105 | – | 8.76 | – | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 16 | 30 | – | 124 | – | 9.52 | – | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 19 | 30 | – | 154 | – | 10.69 | – | 121 | – |

Threadolet Dimension

| DN | NPS | DN | NPS | A | D1 | D2 | L | d1 | ||||

| 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | |||||

| 8~900 | 1/4~36 | 6 | 1/8 | 19 | – | 27 | – | 22 | – | 6.7 | 16 | – |

| 10~900 | 3/8~36 | 8 | 1/4 | 19 | – | 27 | – | 22 | – | 10.2 | 16 | – |

| 15~900 | 1/2~36 | 10 | 3/8 | 21 | – | 30 | – | 25 | – | 10.4 | 19 | – |

| 20~900 | 3/4~36 | 15 | 1/2 | 25 | 32 | 38 | 45 | 33 | 42 | 13.6 | 24 | 19 |

| 25~900 | 1~36 | 20 | 3/4 | 27 | 37 | 47 | 52 | 39 | 48 | 13.9 | 30 | 25 |

| 32~900 | 11/4~36 | 25 | 1 | 33 | 40 | 56 | 63 | 48 | 58 | 17.3 | 36 | 33 |

| 40~900 | 11/2~36 | 32 | 11/4 | 33 | 41 | 66 | 72 | 58 | 67 | 18.0 | 45 | 38 |

| 50~900 | 2~36 | 40 | 11/2 | 35 | 43 | 75 | 83 | 64 | 77 | 18.4 | 51 | 49 |

| 65~900 | 21/2~36 | 50 | 2 | 38 | 52 | 90 | 104 | 77 | 93 | 19.2 | 65 | 59 |

| 80~900 | 3~36 | 65 | 21/2 | 46 | – | 105 | – | 94 | – | 28.9 | 76 | – |

| 100~900 | 4~36 | 80 | 3 | 51 | – | 124 | – | 114 | – | 30.5 | 94 | – |

| 125~900 | 5~36 | 100 | 4 | 57 | – | 154 | – | 140 | – | 33.0 | 121 | – |

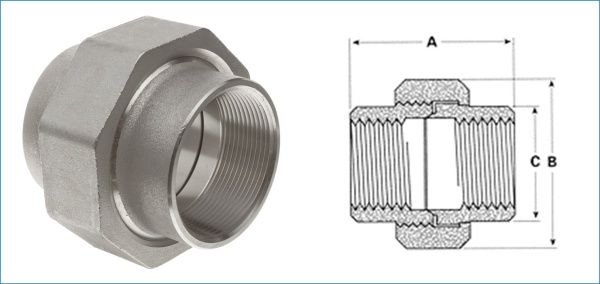

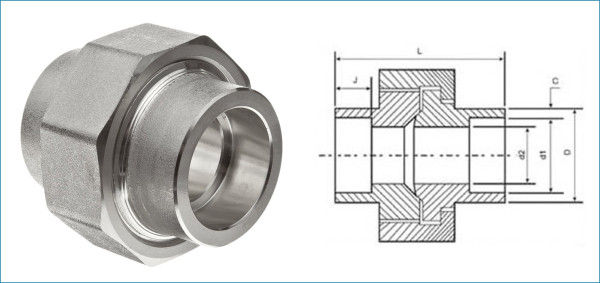

MSS SP-83 Forged Fittings Standard

MSS SP 83 is the specification for socket weld and threaded union which cover size tolerance, marking, material etc.MSS SP-83 union is an active pipe connection fitting with the feature of easy for assemble and disassemble. It can be widely used in different diameters pipeline connection, and the connection of meter and valve with pipe line.

We Can Supplied MSS SP-83 Union scope

| Size | 1/8″ to 3″ ( DN6 to DN80) |

| Pressure Rating | Class 3000 |

| Standard | MSS SP-83 |

| Type | Socket Weld Union and Threaded Union |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L/F51/F55 |

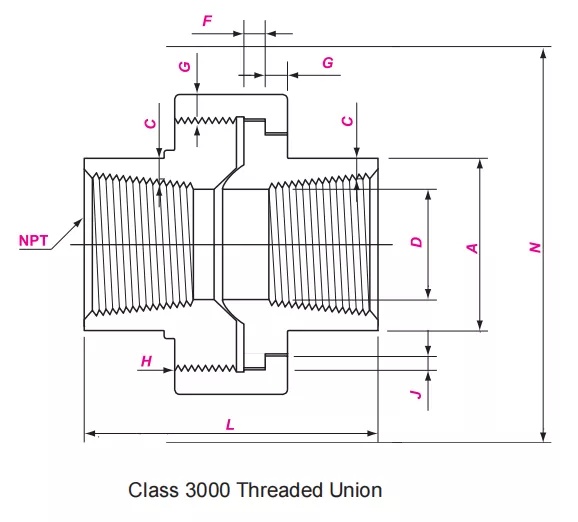

Class 3000 Threaded Union Dimension

| Nominal Size | Pipe End | Wall | Bone | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem Nut | |

| DN | NPS | A min | C min | D | F min | G min | H | J min | L nom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 6.4 | ||||||||||

| 8 | 1/4 | 19.1 | 3 | 11.1 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 9.4 | ||||||||||

| 10 | 3/8 | 22.9 | 3.2 | 14.3 | 3.4 | 3.4 | 14 | 1.4 | 46 | 56 |

| 13.5 | ||||||||||

| 15 | 3/4 | 27.7 | 3.7 | 17.9 | 3.7 | 3.7 | 14 | 1.5 | 49 | 59 |

| 17.1 | ||||||||||

| 20 | 1/2 | 33.5 | 3.9 | 23 | 4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 21.4 | ||||||||||

| 25 | 1 | 41.4 | 4.5 | 29 | 4.6 | 4.4 | 11 | 1.9 | 62 | 79 |

| 27.7 | ||||||||||

| 32 | 1-1/4 | 50.5 | 4.9 | 37.7 | 5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 35.4 | ||||||||||

| 40 | 1-1/2 | 57.2 | 5.1 | 43.5 | 5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 41.2 | ||||||||||

| 50 | 2 | 70.1 | 5.5 | 55.6 | 6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 52.1 | ||||||||||

| 65 | 2-1/2 | 85.3 | 7 | 66.3 | 7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 64.3 | ||||||||||

| 80 | 3 | 102.4 | 7.6 | 82.6 | 8.3 | 8 | 8 | 3.5 | 109 | 176 |

Class 3000 Socket Weld Union Dimension

| DN | NPS | A | B | C | D | E | F | G | H | J | K | L | N |

| 6 | 1/8 | 21.8 | 10.9 | 3.2 | 6.1 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 8 | 1/4 | 21.8 | 14.3 | 3.3 | 8.5 | 20.7 | 3.2 | 3.2 | 16 | 1.2 | 9.7 | 41.4 | 51 |

| 10 | 3/8 | 25.9 | 17.7 | 3.5 | 11.8 | 23.8 | 3.4 | 3.4 | 14 | 1.4 | 9.7 | 46 | 56 |

| 15 | 3/4 | 31.2 | 21.9 | 4.1 | 15 | 23.8 | 3.7 | 3.7 | 14 | 1.5 | 9.7 | 49 | 59 |

| 20 | 1/2 | 37.1 | 27.3 | 4.3 | 20.2 | 28.6 | 4.1 | 4.1 | 11 | 1.7 | 12.7 | 56.9 | 66 |

| 25 | 1 | 45.5 | 34 | 5 | 25.9 | 30.2 | 4.6 | 4.4 | 11 | 1.9 | 12.7 | 62 | 79 |

| 32 | 1-1/4 | 54.9 | 42.8 | 5.3 | 34.3 | 36.6 | 5.3 | 5.2 | 10 | 2.1 | 12.7 | 71.1 | 94 |

| 40 | 1-1/2 | 61.5 | 48.9 | 5.5 | 40.1 | 38.1 | 5.8 | 5.6 | 10 | 2.3 | 12.7 | 76.5 | 112 |

| 50 | 2 | 75.2 | 61.2 | 6 | 51.7 | 41.4 | 6.6 | 6.4 | 10 | 2.7 | 15.7 | 86.1 | 132 |

| 65 | 2-1/2 | 91.7 | 73.9 | 7.7 | 61.2 | 56.9 | 7.5 | 7.1 | 8 | 3.1 | 15.7 | 102.4 | 150 |

| 80 | 3 | 109.2 | 89.9 | 8.3 | 76.4 | 58.7 | 8.3 | 8 | 8 | 3.5 | 15.7 | 109 | 176 |

Application of Forged Fittings

Petroleum

Chemical Industry

Medicine

Electric Power

Fire Prevention

Metallurgy

Shipbuilding

Environmental Protection

Advantage

Corrosion resistant

Highly durable

Lightweight

Low maintenance

Long service life

Forged fittings are basically used for piping and tubing systems to connect and change direction of the flow that conveys liquid, gas, and occasionally solid materials.When selecting and using forged fittings, attention should be paid to their quality and performance to ensure the safety, stability, and efficiency of fluid transportation, providing reliable guarantees for fluid transportation systems in various industries.