Stainless steel threaded coupling is important pipeline connection fittings. It’s widely used in industries such as petroleum, natural gas, and chemical. It fixes and connects stainless steel pipes through threaded connections, achieving a tight connection between pipes and ensuring the sealing and stability of the pipeline system. Stainless steel threaded coupling can withstand certain pressure and temperature, meeting the needs of various pipeline systems.

Types of Threaded Coupling

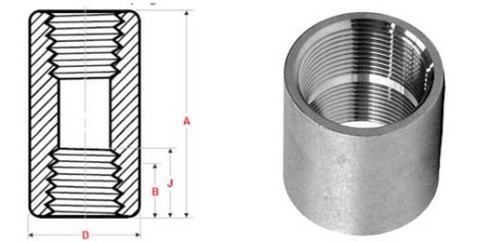

Stainless steel threaded coupling is connected by threads, with a simple and fast installation process, easy disassembly, low maintenance costs in the later stage, and no need for complex welding or flange connections. According to the type of coupling, it can be divided into full threaded coupling and half threaded coupling.

Both ends have threads, which allows it to be connected to two pipes or other fittings with external threads at the same time. This dual ended connection method improves the flexibility and stability of the connection.

One end has threads, which makes it easy to connect with pipes or other fittings with internal threads. This connection method is simple and fast, and has a certain degree of self-locking, which helps prevent loosening.

ASTM A182 Stainless Steel Threaded Coupling

The commonly used materials for stainless steel threaded coupling include ASTM A182 F304/F316/F44; and duplex stainless steel F51/F53. These stainless steel material has excellent corrosion resistance and high temperature performance, which can meet the needs of different working conditions.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

Advantage of Stainless Steel Threaded Coupling

High quality materials

Standardized design

Good sealing performance

Wide applicability

Easy installation

Good sealing

Corrosion and high temperature resistance

ASME B16.11 Stainless Steel Threaded Coupling

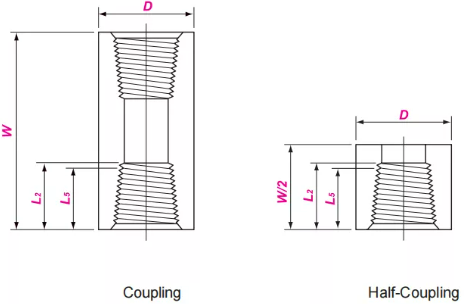

Stainless steel threaded coupling is a pipe connection fittings comply with the ASME B16.11 standard. This standard specifies in detail the dimensions, materials, manufacturing requirements, testing methods of threaded coupling to ensure product quality and interchangeability.

ASME B16.11 stainless steel threaded couplings are mainly used to connect two pipes or fittings with external threads. By tightly fitting their internal threads with the external threads of the pipes or fittings, they achieve sealing and connection of the pipes. The selection of stainless steel material makes the pipe clamp have good corrosion resistance and oxidation resistance, suitable for various corrosive media and high temperature environments.

Dimension

| DN | NPS | W | D | L 5 min | L 2 min | |

| 3000 & 6000 | 3000 | 6000 | ||||

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1¼ | 67 | 57 | 64 | 17.0 | 18.0 |

| 40 | 1½ | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19.0 | 19.2 |

| 65 | 2½ | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 140 | 159 | 27.7 | 33.0 |

Weight Chart (KG)

| Nominal Size | THRD Coupling | |

| D N | NPS | 6000 |

| 6 8 10 | 1/8 1/4 3/8 | 0.09 0.13 0.24 |

| 15 20 25 | 1/2 3/4 1 | 0.40 0.52 1.06 |

| 32 40 50 | 11/4 11/2 2 | 1.32 2.20 3.37 |

| 65 80 100 | 21/2 3 4 | 4.81 7.25 12.0 |

Application and Installation

ASME B16.11 stainless steel threaded couplings are widely used in pipeline systems in industries such as petroleum, chemical, natural gas, water treatment, pharmaceuticals, and food. Especially in situations where high corrosion resistance and sealing are required, such as corrosive medium transportation pipelines in the chemical industry and sanitary pipelines in the food processing industry, this pipe clamp plays an important role.

The installation and disassembly of stainless steel threaded coupling is relatively simple. During installation, simply screw the pipe clamp into the thread of the pipeline and tighten it appropriately. When disassembling, simply rotate the pipe clamp in the opposite direction to remove it from the pipeline. This simple installation and disassembly method makes stainless steel threaded pipe clamps very popular in the maintenance and renovation of pipeline systems.

Inspection

The production and use of stainless steel threaded coupling usually follow relevant international or domestic standards and specifications, such as ASME B16.11. These standards and specifications provide detailed regulations on the size, material, performance, inspection, and other aspects of pipe clamps to ensure their quality and safety.