Stainless steel butt weld elbow is made of stainless steel as raw material, which is formed by hot pressing. It’s connection form is to directly weld the elbow to the steel pipe, thereby achieving the connection and turning of the pipeline. It have certain pressure resistance and can maintain a stable connection state in high-pressure environments.

The process of butt weld elbow usually includes steps material selection, cutting, forming, heat treatment, welding, polishing, testing. During the production process, the pipes are bent and formed by hot pressing or forging, and heat treatment is also required to enhance their compressive strength and achieve better forming results. Among them, forming is one of the key links, which determines the shape and dimensional accuracy of the elbow; Heat treatment and welding have a significant impact on the mechanical properties and corrosion resistance of elbows.

Stainless steel butt welded elbows are widely used in various industrial fields due to their excellent material, corrosion resistance, high temperature resistance, high strength, easy cleaning and maintenance, and other advantages.

Types of Stainless Steel Butt Weld Elbow

There are various types of stainless steel butt welded elbows, which are widely used.

Classified by Bending Radius

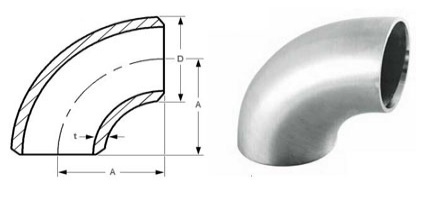

Stainless steel butt weld elbow can be divided into long radius and short radius according to different bending radius.

Classified by Bending Angle

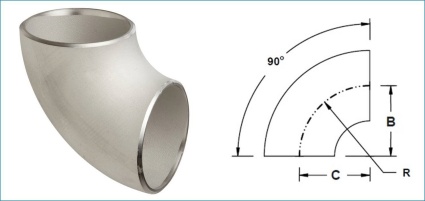

Stainless steel butt weld elbow can be divided into 45 degree ,90 degree, and 180 degree elbows according to the bending angle.

Classified by Material

Stainless steel butt weld elbow is classified according to the specific type of SS304, 316, etc.

Characteristics of Stainless Steel Materials

Stainless steel butt weld elbow include strong corrosion resistance, good high-temperature resistance, as well as significant economic and environmental benefits. These characteristics have made stainless steel butt welded elbows widely used and favored in various industrial fields.

ASTM A403 is the standard material for butt weld elbow. Covering common stainless steel materials such as 304/304L, 316/316L, 321, 347, and 904L.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 28 min | 28 min |

ANSI/ASME B16.9 Butt Weld Elbow

The American standard ANSI/ASME B16.9 elbow, in layman’s terms, refers to an elbow produced according to the American standards. ANSI is the American national standard, and ASME is the American Society of Mechanical Engineers standard. ASME standards and ANSI standards cover the vast majority of industrial fields, including materials, processing, processes, experiments, and more. ASME cites many ANSI standards.

Stainless steel butt weld elbows produced according to ASME B16.9 have a wide range of sizes ranging 1/2 “to 48”. Common wall thickness pressure levels include Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, etc. Among them, the most commonly used are STD and XS.

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

Dimension of ASME B16.9 Butt Weld 90 Deg Elbow

| Nominal size | Outside Diameter at Bevel | Center to End | ||

| 90° Elbows | ||||

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | – |

| 20 | 3/4 | 26.7 | 38 | – |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 400 | 16 | 406.4 | 610 | 406 |

| 450 | 18 | 457.0 | 686 | 457 |

| 500 | 20 | 508.0 | 762 | 508 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1448 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

The production standard characteristics of stainless steel butt welded elbows are mainly reflected in standardization and normalization. These characteristics jointly ensure that the quality and performance of stainless steel butt welded elbows meet relevant standards and requirements.

The stainless steel butt weld elbow produced by ZIZI Engineering Co Ltd comply with the ASTM A403 material standard.