Stainless steel reducer,is a special type of stainless steel pipe fitting mainly used to connect two pipes with different diameters. According to different structures, it can be divided into stainless steel concentric reducer and eccentric reducer.

Stainless steel concentric reducers are widely used in pipeline systems,and today we will take a detailed look at their characteristics.

Feature Structural of Stainless Steel Concentric Reducer

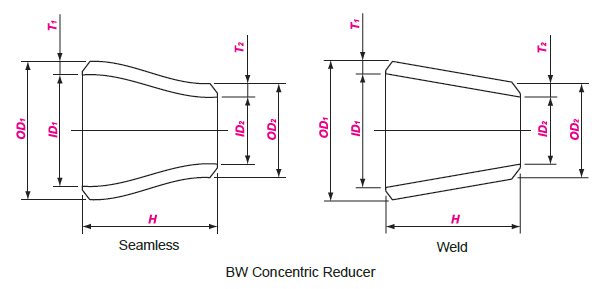

Stainless steel concentric reducer adopts a concentric structure design. The centers of the two ends of the pipe fittings are located on the same center line. This design ensures that the center line of the two ends of the pipeline is aligned when connecting the concentric reducer, thus achieving a smooth transition and connection.

Concentric reducer shape is similar to a conical joint, used to expand or reduce the diameter of the centerline. This conical structure allows the fluid to gradually adapt to changes in aperture as it passes through, reducing fluid resistance. The internal structure has high stability and can resist the erosion of various chemical media, ensuring the long-term stable operation of the pipeline.

Process of Stainless Steel Concentric Reducer

Reduced diameter pressing

Expanding and pressing

Reduction and expansion compression

Stamping forming

Dimension of ASME B16.9 Concentric Reducer

Stainless steel concentric reducer belongs to butt welded pipe fittings, produced according to the American standard ASME B16.9 production standard. It’s size features are reflected in its wide range of specifications, diverse wall thickness dimensions, wide application fields, and high customization. These characteristics make it an indispensable and important component in pipeline systems.

| Size Range | 3/4″ – 60″ / DN20 – 1500 |

| Thickness Schedule | SCH 10 – SCH 80, SCH 160, XXS |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| OD1 | OD2 | END TO END |

| NPS | NPS | H |

| 3/4 | 3/8 – 1/2 | 38 |

| 1 | 1/2 – 3/4 | 51 |

| 1-1/4 | 1/2 – 1 | 51 |

| 1-1/2 | 1/2 – 1-1/4 | 64 |

| 2 | 3/4 – 1-1/2 | 76 |

| 2-1/2 | 1 – 2 | 89 |

| 3 | 1-1/4 – 2-1/2 | 102 |

| 4 | 2 – 3-1/2 | 102 |

| 5 | 2 – 4 | 127 |

| 6 | 2-1/2 – 5 | 140 |

| 8 | 3-1/2 – 6 | 152 |

| 10 | 4 – 8 | 178 |

| 12 | 5 – 10 | 203 |

| 14 | 6 – 12 | 330 |

| 16 | 6 – 14 | 356 |

| 18 | 8 – 16 | 381 |

| 20 | 10 – 18 | 508 |

| 22 | 12 – 20 | 508 |

| 24 | 12 – 22 | 508 |

| 26 | 12 – 24 | 610 |

| 28 | 14 – 26 | 610 |

| 30 | 14 – 28 | 610 |

| 32 | 20 – 30 | 610 |

| 34 | 22 – 32 | 610 |

| 36 | 22 – 34 | 610 |

| 38 | 24 – 36 | 610 |

| 40 | 28 – 38 | 610 |

| 42 | 28 – 40 | 610 |

| 44 | 32 – 42 | 610 |

| 46 | 34 – 44 | 711 |

| 48 | 36 – 46 | 711 |

| 52 | 40 – 48 | 711 |

| 56 | 40 – 52 | 711 |

| 60 | 44 – 56 | 711 |

Feature of Stainless Steel Materials

Stainless steel concentric reducer is mainly made of stainless steel materials, such as 304, 316, 316L, etc. These materials have good corrosion resistance, high temperature strength, excellent mechanical properties, high precision of inner and outer surfaces, easy processing and connection, and long service life. These features make them widely used in various pipeline systems.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | ||

| ASTM A403 WP316 | MIN | 10.0 | 16.0 | 2.00 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 |

Mechanical Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP316 |

| T.S (MPA) | 515 min | 515 min |

| Y.S (MPA) | 205 min | 205 min |

| EL % | 28 min | 28 min |

Application

Petrochemical Industry

Thermal Power Generation Industry

The Pharmaceutical Industry

Food Processing Industry

Shipbuilding Industry

Chemical Industry

Nuclear Industry

In these industries, pipeline systems often face various complex environmental factors such as high temperature, high pressure, and corrosion. The use of stainless steel concentric reducer can effectively improve the safety and reliability of equipment. Stainless steel concentric reducers are widely used in multiple industries and fields due to their excellent corrosion resistance, high-temperature strength, cleanliness, and hygiene standards, ensuring the safe, reliable, and efficient operation of pipeline systems.