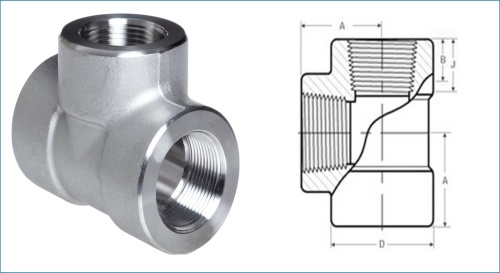

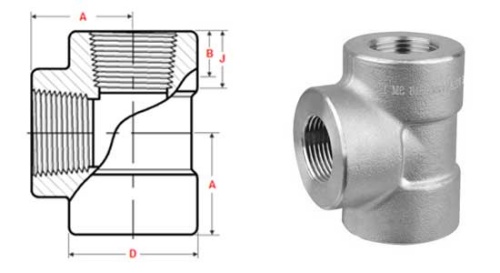

Stainless steel threaded tee is a commonly used pipe fitting in pipeline systems. It is made of stainless steel material and has three ends. Two ends are on the same straight line, and the third end is perpendicular or at a certain angle to these two openings. It adopts a threaded connection method to connect the pipeline, which is convenient for installation and disassembly.

Stainless steel threaded tees generally consist of a main body and a threaded connection part. The main body is usually made of stainless steel material, which has sufficient strength and corrosion resistance. The threaded connection part is used to connect with other pipeline fittings.

Stainless steel threaded tee, as important fittings in pipeline systems, play a crucial role in multiple industries.

Types of Stainless Steel Threaded Tee

According to the end size , threaded tee can be divided into two forms: equal and reducing tee.

Equal threaded tee refers to a threaded tee pipe fitting with three completely equal diameters at the connection interface. It has a simple structure, easy connection, and is suitable for connecting pipes of the same diameter.

Reducing threaded tee refers to a threaded tee fitting where the diameter of the branch end is not equal to that of the main pipe end. It can achieve the diversion of fluid from one pipe to two pipes of different diameters, or the merging of fluid from two pipes of different diameters into one pipe.

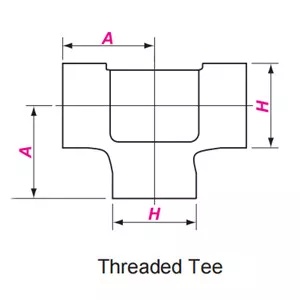

Dimension of ASME B16.11 Threaded Tee

The main manufacturing standards for stainless steel threaded tees include GB/T14626, ASME B16.11, BS3799, etc. These standards specify requirements for product dimensions, tolerances, performance, etc., ensuring product quality and interchangeability.

ZIZI ENGEERING CO LTD specializes in producing forged pipe fittings made of American standard ASME B16.11 carbon steel, alloy steel, stainless steel and other materials, which are exported to various parts of the world.

| DN | NPS | A | H | ||||

| 2000LB | 3000LB | 6000LB | 2000LB | 3000LB | 6000LB | ||

| 6 | 1/8 | 21 | 21 | 25 | 22 | 22 | 25 |

| 8 | 1/4 | 21 | 25 | 28 | 22 | 25 | 33 |

| 10 | 3/8 | 25 | 28 | 33 | 25 | 33 | 38 |

| 15 | 1/2 | 28 | 33 | 38 | 33 | 38 | 46 |

| 20 | 3/4 | 33 | 38 | 44 | 38 | 46 | 56 |

| 25 | 1 | 38 | 44 | 51 | 46 | 56 | 62 |

| 32 | 1 ¼ | 44 | 51 | 60 | 56 | 62 | 75 |

| 40 | 1 ½ | 51 | 60 | 64 | 62 | 75 | 84 |

| 50 | 2 | 60 | 64 | 83 | 75 | 84 | 102 |

| 65 | 2 ½ | 76 | 83 | 95 | 92 | 102 | 121 |

| 80 | 3 | 86 | 95 | 106 | 109 | 121 | 146 |

| 100 | 4 | 106 | 114 | 114 | 146 | 152 | 152 |

Weight List of Stainless Steel Threaded Tee

| NOMINAL SIZE | THREADED PIPE TEE WEIGHT | |||

| DN | NPS | 2000 | 3000 | 6000 |

| 6 | 1/8 | 0.13 | 0.22 | 0.35 |

| 8 | 1/4 | 0.13 | 0.22 | 0.57 |

| 10 | 3/8 | 0.16 | 0.40 | 0.66 |

| 15 | 1/2 | 0.35 | 0.58 | 1.15 |

| 20 | 3/4 | 0.45 | 0.90 | 1.80 |

| 25 | 1 | 0.66 | 1.46 | 2.25 |

| 32 | 1-1/4 | 1.00 | 1.90 | 3.95 |

| 40 | 1-1/2 | 1.40 | 3.40 | 4.87 |

| 50 | 2 | 2.20 | 3.80 | 8.89 |

| 65 | 2-1/2 | 4.20 | 7.20 | 12.8 |

| 80 | 3 | 6.15 | 10.7 | 21.6 |

| 100 | 4 | 14.7 | 17.9 | 29.5 |

Stainless Steel Threaded Tee VS Butt Weld Tee

Stainless Steel Threaded Tee

Connection method: Using threaded connection, only two threaded interfaces need to be tightened during installation to achieve connection, making the operation simple and fast.

Features: Stainless steel threaded tee have the advantage of easy installation.

Stainless Steel Butt Weld Tee

Connection method: Welding connection is used, which requires professional welding technology and equipment for operation.

Features: Stainless steel butt welded tee have excellent sealing and pressure bearing capabilities, and can operate stably for a long time in harsh working environments.

Application

Stainless steel threaded tee have the features of strong corrosion resistance, easy installation, and are widely used in pipeline systems in various industries.

Petrochemical industry

Chemical production

Construction field

Drainage system

Food processing