This order we got the enquiry about concentric swage nipple from the client first on whatsapp, I noticed the account number shew him is from Tanzania and I happened to do business in Tanzania for a while, so the communication between went very smoothly, besides we have offered satisfying answer about the technical and transportation , therefore the order went to us without concern.

Concentric Swage Nipple Specification

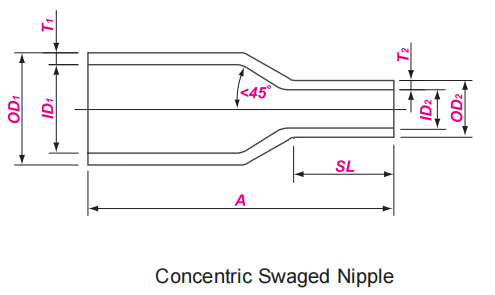

A concentric swage nipple is a type of pipe fitting used to connect pipes of different diameters in a straight line. It is tapered and has a uniform, symmetrical design that ensures a smooth transition between two sections of pipe. The term “concentric” refers to the fact that the smaller pipe diameter is aligned concentrically (centered) with the larger pipe diameter, resulting in a smooth, gradual change in size.

| Shape | Concentric |

| Size Range | 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 3 1/2″, 4″, 5″, 6″, 8″, 10″, 12″ |

| Thickness Schedule | Sch 10 / 20 / 30 / STD / 40 / 60 / XS / 80 / 100 / 120 / 140 / 160 / XXS |

| Standard | MSS SP-95, SH/T3419 |

| Material | Carbon Steel, Alloy Steel, Stainless Steel, Duplex Stainless Steel |

Material Grades of Swage Nipple

Carbon Steel: ASTM A106 B, A333 Grade 3, 6, 9. API 5L X52, X60, X65, X70

Alloy Steel: ASTM A182 F1, F5, F9, F11, F12, F22, F91

Stainless Steel: ASTM A182 F316/316L, F304/304L, F317, F321, F310

Duplex Steel: ASTM A182 F51, F53, F55, S 31803, S 32205, S 32550, S 32750, S32760

MSS SP-95 Concentric Swage Nipple Dimensions

| Nominal Size | OD at End | Length of Small End | End to End | Nominal Size | OD at End | Length of Small End | End to End | |||

| DN | NPS | OD X OD | SL min | A | DN | NPS | ODX OD | SL min | A | |

| 8×6 | 1/4×1/8 | 13.7×10.3 | 20 | 57 | 65×6 65×8 65×10 65×15 65×20 65×25 65×32 65×40 65×50 | 21/2×1/8 21/2×1/4 21/2×3/8 21/2×1/2 21/2×3/4 21/2×1 21/2×11/4 21/2×11/2 21/2×2 | 73.0×10.3 73.0×13.7 73.0×17.1 73.0×21.3 73.0×26.7 73.0×33.4 73.0×42.2 73.0×48.3 73.0×60.3 | 22 22 22 25 25 30 30 40 40 | 178 | |

| 10×6 10×8 | 3/8×1/8 3/8×1/4 | 17.1×10.3 17.1×13.7 | 20 20 | 64 | ||||||

| 15×6 15×8 15×10 | 1/2×1/8 1/2×1/4 1/2×3/8 | 21.3×10.3 21.3×13.7 21.3×17.1 | 20 20 20 | 70 | ||||||

| 20×6 20×8 20×10 20×15 | 3/4×1/8 3/4×1/4 3/4×3/8 3/4×1/2 | 26.7×10.3 26.7×13.7 26.7×17.1 26.7×21.3 | 20 20 22 22 | 76 | ||||||

| 80×6 80×8 80×10 80×15 80×20 80×25 80×32 80×40 80×50 80×65 | 3×1/8 3×1/4 3×3/8 3×1/2 3×3/4 3×1 3×11/4 3×11/2 3×2 3×21/2 | 88.9×10.3 88.9×13.7 88.9×17.1 88.9×21.3 88.9×26.7 88.9×33.4 88.9×42.2 88.9×48.3 88.9×60.3 88.9×73.0 | 22 22 22 25 25 30 30 40 40 40 | 203 | ||||||

| 25×6 25×8 25×10 25×15 25×20 | 1×1/8 1×1/4 1×3/8 1×1/2 1×3/4 | 33.4×10.3 33.4×13.7 33.4×17.1 33.4×21.3 33.4×26.7 | 20 20 22 22 22 | 89 | ||||||

| 32×6 32×8 32×10 32×15 32×20 32×25 | 11/4×1/8 11/4×1/4 11/4×3/8 11/4×1/2 11/4×3/4 11/4×1 | 42.2×10.3 42.2×13.7 42.2×17.1 42.2×21.3 42.2×26.7 42.2×33.4 | 20 20 22 22 25 25 | 102 | ||||||

| 90×6 90×8 90×10 90×15 90×20 90×25 90×32 90×40 90×50 90×65 90×80 | 31/2×1/8 31/2×1/4 31/2×3/8 31/2×1/2 31/2×3/4 31/2×1 31/2×11/4 31/2×11/2 31/2×2 31/2×21/2 31/2×3 | 101.6×10.3 101.6×13.7 101.6×17.1 101.6×21.3 101.6×26.7 101.6×33.4 101.6×42.2 101.6×48.3 101.6×60.3 101.6×73.0 101.6×88.9 | 22 22 22 25 25 30 30 40 40 40 40 | 203 | ||||||

| 40×6 40×8 40×10 40×15 40×20 40×25 40×32 | 11/2×1/8 11/2×1/4 11/2×3/8 11/2×1/2 11/2×3/4 11/2×1 11/2×11/4 | 48.3×10.3 48.3×13.7 48.3×17.1 48.3×21.3 48.3×26.7 48.3×33.4 48.3×42.2 | 20 20 22 25 25 25 25 | 114 | ||||||

| 50×6 50×8 50×10 50×15 50×20 50×25 50×32 50×40 | 2×1/8 2×1/4 2×3/8 2×1/2 2×3/4 2×1 2×11/4 2×11/2 | 60.3×10.3 60.3×13.7 60.3×17.1 60.3×21.3 60.3×26.7 60.3×33.4 60.3×42.2 60.3×48.3 | 20 22 22 25 30 30 30 30 | 165 | ||||||

| 100×8 100×10 100×15 100×20 100×25 100×32 | 4×1/4 4×3/8 4×1/2 4×3/4 4×1 4× 11/4 | 114.3×13.7 114.3×17.1 114.3×21.3 114.3×26.7 114.3×33.4 114.3×42.2 | 25 25 25 30 30 40 | 229 | ||||||

How Many End Types of MSS SP 95 Concentric Swage Nipples

– Bevel of Both Ends ( BBE)

– Plain of Both Ends ( PBE)

– Thread of Both Ends ( TBE)

– Bevel of Large End / Plain of Small End ( BLE/PSE)

– Bevel of Large End / Thread of Small End ( BLE/TSE)

– Plain of Large End / Thread of Small End ( PLE/TSE)

– Plain of Large End / Bevel of Small End ( PLE/BSE)

– Thread of Large End / Bevel of Small End ( TLE/BSE)

– Bevel of Large End / Thread of Small End ( BLE/TSE)

How to inspect concentric swage nipple?

Inspecting a concentric swage nipple is important to ensure its integrity, proper fit, and functionality in the piping system. Since these fittings are often used in high-pressure and high-temperature applications, a thorough inspection is crucial to prevent leaks, failures, or other issues down the line.

Dimensional Inspection

Ensure that the concentric swage nipple matches the required specifications, including the dimensions of the pipe sizes, wall thickness, and overall length.

Outer Diameter (OD) of both the large and small ends to ensure they match the nominal pipe size.

Inner Diameter (ID) of the nipple at both ends to check if they align with the pipe’s internal diameter. This is particularly important to avoid creating a bottleneck or flow restriction.

Length: Measure the overall length of the swage nipple to ensure it meets the design specifications. An incorrect length can result in poor fitting or failure to connect properly to pipes.

Wall Thickness: Verify that the wall thickness of the concentric swage nipple is consistent and meets the standard for the application. A thinner wall can lead to failure under pressure.

Concentric Swage Nipple Applications

Our Concentric Swage Nipple is used in various applications and industries. Below are a few of them:

· Oil & Gas Industries

· Gas Processing Industries

· Food Processing Industries

· Petrochemical Industries

· Chemical Industries

· Power Generation Industries

· Sugar Industries

· Fertilizers Industries