Stainless steel socket weld cross is a widely used pipe connection accessory in pipeline systems. It’s a pipe fitting used in pipeline systems to change the direction of pipelines. The design of the socket enhances the stability of the connection and prevents fluid leakage. The curved part is used to change the direction of the pipeline.

Stainless steel socket weld cross is widely used in pipeline systems of petroleum, chemical, shipping and other industries. It’s corrosion resistance and wear resistance make it outstanding in these fields.

Types of Stainless Steel Socket Weld Cross

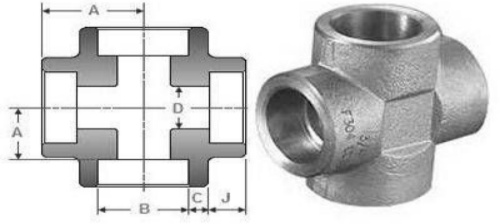

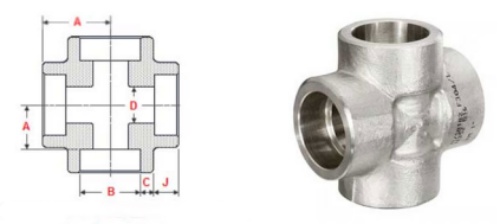

Stainless steel socket weld cross can be divided into equal cross and reducing cross according to the ends size. In the piping system, socket weld cross are fittings that change the direction of the piping. ZIZI ENGEERING CO LTD specializes in producing and supplying socket weld cross in accordance with the ASME B16.11 standard. The specifications ranging from 1/8 “to 4” and pressures of Class 3000, 6000, and 9000.

| Size | from 1/8″ to 4″ (DN6-DN100) |

| Pressure | 3000LB, 6000LB, 9000LB |

| Thickness | Sch80, Sch160, SchXXS |

| Type | Socket Weld Equal Cross & Reducing Cross |

| Standard | ASME B16.11 BS3799 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

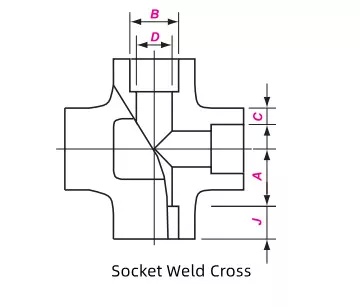

Dimension of ASME B16.11 Stainless Steel Socket Weld Cross

ASME B16.11 is one of the main manufacturing standards for socket weld cross. It specifies requirements for the design, manufacturing, inspection, and labeling of socket cross. In addition, socket cross may also comply with other standards such as GB/T14383, BS3799, etc.

| DN | NPS | B | D | C | Jmin | A | |||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Cross | |||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | |||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | – | 3.18 | 3.18 | 3.96 | 3.43 | – | – | 9.5 | 11 | 11 | – |

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | – | 3.78 | 3.3 | 4.6 | 4.01 | – | – | 9.5 | 11 | 13.5 | – |

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | – | 4.01 | 3.5 | 5.03 | 4.37 | – | – | 9.5 | 13.5 | 13.5 | – |

| 15 | 1/2 | 21.9 | 15 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 9.5 | 15.5 | 19 | 25.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 19 | 22.5 | 28.5 |

| 25 | 1 | 34.0 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 22.5 | 27 | 32 |

| 32 | 1 ¼ | 42.8 | 34.3 | 28.7 | 22 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 27 | 32 | 35 |

| 40 | 1 ½ | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 12.5 | 32 | 38 | 38 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 16 | 38 | 41 | 54 |

| 65 | 2 ½ | 73.9 | 61.2 | – | – | 8.76 | 7.62 | – | – | – | – | 16 | 41 | – | – |

| 80 | 3 | 89.9 | 76.4 | – | – | 9.52 | 8.30 | – | – | – | – | 16 | 57 | – | – |

| 100 | 4 | 115.5 | 100.7 | – | – | 10.69 | 9.35 | – | – | – | – | 19 | 66.5 | – | – |

Weight List (KG)

| Nominal size | SW Cross | |||

| DN | NPS | 3000 | 6000 | 9000 |

| 6 | 1/8 | 0.15 | 0.21 | – |

| 8 | 1/4 | 0.15 | 0.25 | – |

| 10 | 3/8 | 0.19 | 0.54 | – |

| 15 | 1/2 | 0.46 | 0.64 | 1.32 |

| 20 | 3/4 | 0.59 | 1.09 | 2.25 |

| 25 | 1 | 0.81 | 1.97 | 2.69 |

| 32 | 1¼ | 1.19 | 2.34 | 4.68 |

| 40 | 1½ | 1.67 | 3.90 | 7.84 |

| 50 | 2 | 2.59 | 6.15 | 10.5 |

| 65 | 2½ | 4.95 | – | – |

| 80 | 3 | 7.25 | – | – |

| 100 | 4 | 18.8 | – | – |

ASTM A182 Stainless Steel Socket Weld Cross

According to ASTM A182 standard, the chemical composition and mechanical properties of stainless steel socket weld cross must meet specific requirements, such as tensile strength, yield strength, elongation, and hardness, all of which must meet the range specified in the standard. They are mainly made of high-quality stainless steel materials, such as 304, 316 and other stainless steel grades. These materials not only have excellent corrosion resistance, but also have good strength and toughness, and can withstand high working pressure and temperature.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| ASTM A182 F304 | MIN | 8.0 | 18.0 | ||||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | |||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 | ||

| ASTM A182 F44 | MIN | 17.50 | 19.50 | 6.00 | 0.50 | ||||||

| MAX | 0.02 | 1.00 | 0.030 | 0.010 | 0.80 | 18.50 | 20.50 | 6.50 | 1.00 | ||

| ASTM A182 F51 | MIN | 4.50 | 21.00 | 2.50 | 0.08 | ||||||

| MAX | 0.03 | 2.00 | 0.030 | 0.020 | 1.00 | 6.50 | 23.00 | 3.50 | 0.20 | ||

| ASTM A182 F53 | MIN | 6.00 | 24.00 | 3.00 | 0.24 | ||||||

| MAX | 0.03 | 1.20 | 0.035 | 0.020 | 0.80 | 8.00 | 26.00 | 5.00 | 0.32 | 0.5 |

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F44 | ASTM A182 F51 | ASTM A182 F53 |

| T.S (MPA) | 515 min | 515 min | 650 min | 620 min | 800 min |

| Y.S (MPA) | 205 min | 205 min | 300 min | 450 min | 550 min |

| EL % | 30 min | 30 min | 35 min | 35 min | 25 min |

| R/A % | 50 min | 50 min | 50 min | 45 min | 15 min |

| HARDNESS | 310 max |

ASTM A182 stainless steel socket weld cross have gained widespread recognition and application for their excellent materials, reasonable design, exquisite manufacturing processes, and reliable quality assurance.

Advantage

Excellent corrosion resistance

Wear resistance

High strength

Easy installation and space saving

Good sealing performance

Low long-term usage cost