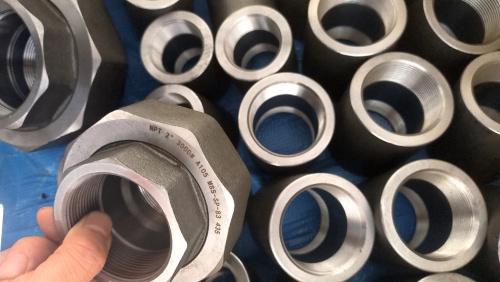

Class 3000 threaded union refers to a pipe connector with threads. It is the most common pipe fitting in industry and life. It can withstand connections under high pressure and ensure the reliability and safety of pipe connections. Threaded unions make pipe connections simpler and easier to disassemble and replace, greatly saving the cost of pipe connections.

It is widely used in civil construction, plumbing engineering, automobile manufacturing, shipbuilding, petroleum, chemical industry, aerospace and other fields to connect various pipes and components.

Specification of Class 3000 Threaded Union

The sizes of threaded union range from 1/8″ to 3″, and the pressure is Class 3000.

| Size | 1/8″ to 3″ ( DN6 to DN80) |

| Pressure Rating | Class 3000 |

| Standard | MSS SP-83 |

| Type | Socket Weld Union and Threaded Union |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / F12 / F5 / F9 / F91 / F92 / F22 |

| Stainless Steel | ASTM A182 F304/304L/304H, F316/316L, F310S, F317, F347, F904L/F51/F55 |

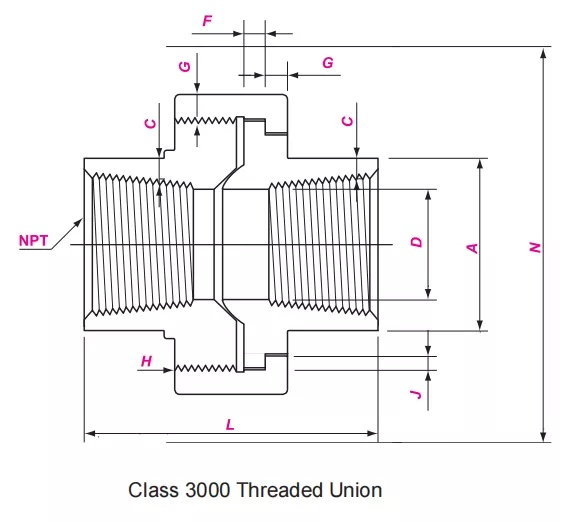

Dimension of Class 3000 Threaded Union

| Nominal Size | Pipe End | Wall | Bone | Male Flange | Nut | THRD Per Inch | Bearing | Length Assem | Clear Assem Nut | |

| DN | NPS | A min | C min | D | F min | G min | H | J min | L nom | N |

| 6 | 1/8 | 14.7 | 2.4 | 8.4 6.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 8 | 1/4 | 19.1 | 3.0 | 11.1 9.4 | 3.2 | 3.2 | 16 | 1.2 | 41.4 | 51 |

| 10 | 3/8 | 22.9 | 3.2 | 14.3 13.5 | 3.4 | 3.4 | 14 | 1.4 | 46.0 | 56 |

| 15 | 1/2 | 27.7 | 3.7 | 17.9 17.1 | 3.7 | 3.7 | 14 | 1.5 | 49.0 | 59 |

| 20 | 3/4 | 33.5 | 3.9 | 23.0 21.4 | 4.1 | 4.1 | 11 | 1.7 | 56.9 | 66 |

| 25 | 1 | 41.4 | 4.5 | 29.0 27.7 | 4.6 | 4.4 | 11 | 1.9 | 62.0 | 79 |

| 32 | 11/4 | 50.5 | 4.9 | 37.7 35.4 | 5.3 | 5.2 | 10 | 2.1 | 71.1 | 94 |

| 40 | 11/2 | 57.2 | 5.1 | 43.5 41.2 | 5.8 | 5.6 | 10 | 2.3 | 76.5 | 112 |

| 50 | 2 | 70.1 | 5.5 | 55.6 52.1 | 6.6 | 6.4 | 10 | 2.7 | 86.1 | 132 |

| 65 | 21/2 | 85.3 | 7.0 | 66.3 64.3 | 7.5 | 7.1 | 8 | 3.1 | 102.4 | 150 |

| 80 | 3 | 102.4 | 7.6 | 82.6 77.3 | 8.3 | 8.0 | 8 | 3.5 | 109.0 | 176 |

Material of ASME B16.11 Threaded Union

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F304L | MIN | 8.00 | 18.00 | |||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 13.00 | 20.00 | 0.10 | ||

| ASTM A182 F304 | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.10 | ||

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

Manganese plays a major role in strengthening and deoxidizing the steel for threaded unions. The manganese content is generally 2%. A higher manganese content can improve the yield strength and tensile strength of steel.

Mechanical Properties

| MATERIAL | ASTM A182 F304 | ASTM A182 F304L | ASTM A182 F316 |

| T.S (MPA) | 515 min | 485 min | 515 min |

| Y.S (MPA) | 205 min | 170 min | 205 min |

| EL % | 30 min | 30 min | 30 min |

| R/A % | 50 min | 50 min | 50 min |

Tensile strength is the maximum stress that a threaded union can withstand in a tensile test. It reflects the ability of the union to resist fracture. Higher tensile strength ensures that the union will not break when subjected to tension.

Advantages of Class 3000 Threaded Union

Easy connection: Threaded union make pipe connection simpler, and disassembly and replacement are also easier, greatly saving the cost of pipe connection. At the same time, the threaded connection method is also easy to install and disassemble, and does not require complex tools and equipment.

High strength: According to the principle of cold working hardening of steel, the strength of the straight thread rolled on the steel bar is greatly improved, so that the tensile strength of the union is higher than the tensile strength of the steel bar parent material. This high strength makes the union less likely to be damaged when under pressure, ensuring the stability and safety of the connection.

Stable performance: The connection process of the forged union is not affected by the quality of the workers. As long as the operation is carried out in accordance with the specifications, the performance of the connection can be guaranteed to be stable. This stability enables the union to maintain good working condition in various environments.

Strong applicability: Class 3000 threaded union can connect horizontal, vertical, and oblique steel bars of the same or different diameters, and can also be used to connect various pipes and equipment. This wide applicability allows the union to be used in various projects.

Steps for inspecting the union

We are very strict in inspecting the class 3000 threaded union. First, our inspectors will use the selected measuring tools to accurately measure the various dimensions of the union, including the diameter, pitch and other parameters of the union.

The measurement results will be compared with the design drawings or standard requirements of the union to ensure that its various dimensions meet the specification requirements. After that, the union will be subjected to tensile tests using equipment such as tensile testing machines to test its mechanical performance indicators such as tensile strength and elongation.