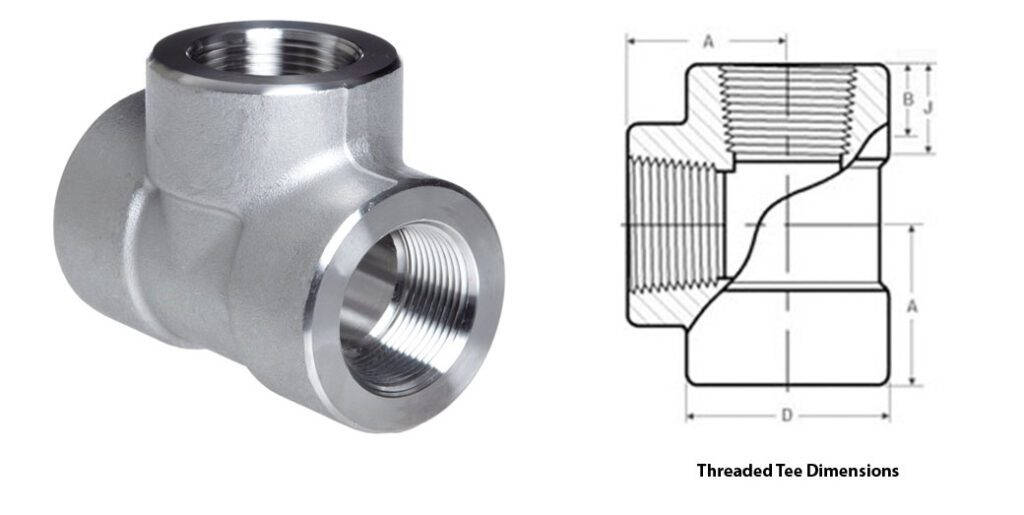

Carbon steel threaded tee refer to three-way pipe fittings with threaded connections at the ends. Depending on the diameter of the ends, they can be divided into equal tee and reducing tee.Equal tee are also known as straight tees. Reducing tees have the same size connecting pipe for the main pipe, but the connecting pipe for the branch pipe is smaller than the main pipe’s connecting pipe.

Carbon steel threaded tee is pipe connectors widely used in plumbing and fluid handling systems, to connect pipes, valves, fittings and other components. Constructed out of ASTM A105 they are known for their durability, excellent resistance to corrosion, rust and chemical damage.

These Carbon steel threaded tee feature either male threads or female threads, which allow them to connect with the corresponding threads of fittings or pipes. These NPT threaded tee have tapered National Pipe Threads (NPT) which create a secure and leak-resistant connection when properly threaded.

Characteristics of ASME B16.11 Carbon Steel Threaded Tee

ASTM B16.11 standard contains pressure-temperature ratings, dimensions, tolerances, markings and material requirements for forged and threaded forged fittings. The relevant contents will be shown in below tables in this article.

We manufacture threaded tee dimensions in accordance with ASME B16.11 / BS 3799. The ASME B16.11 standard covers pressure-temperature ratings, dimensions,marking, tolerances and material requirements. We are specialized in supplying threaded tee in three pressure ratings: class 2000, Class 3000 and 6000 at reasonable price.

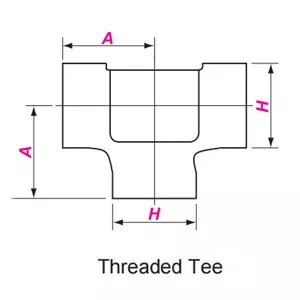

Dimension of Carbon Steel Threaded Tee

| DN | NPS | A | H | ||||

| 2000LB | 3000LB | 6000LB | 2000LB | 3000LB | 6000LB | ||

| 6 | 1/8 | 21 | 21 | 25 | 22 | 22 | 25 |

| 8 | 1/4 | 21 | 25 | 28 | 22 | 25 | 33 |

| 10 | 3/8 | 25 | 28 | 33 | 25 | 33 | 38 |

| 15 | 1/2 | 28 | 33 | 38 | 33 | 38 | 46 |

| 20 | 3/4 | 33 | 38 | 44 | 38 | 46 | 56 |

| 25 | 1 | 38 | 44 | 51 | 46 | 56 | 62 |

| 32 | 1 1/4 | 44 | 51 | 60 | 56 | 62 | 75 |

| 40 | 1 1/2 | 51 | 60 | 64 | 62 | 75 | 84 |

| 50 | 2 | 60 | 64 | 83 | 75 | 84 | 102 |

| 65 | 2 1/2 | 76 | 83 | 95 | 92 | 102 | 121 |

| 80 | 3 | 86 | 95 | 106 | 109 | 121 | 146 |

| 100 | 4 | 106 | 114 | 114 | 146 | 152 | 152 |

Weight Chart of Threaded Tee

| Nominal Size | THD Tee | |||

| DN | NPS | 2000 | 3000 | 6000 |

| 6 8 10 | 1/8 1/4 3/8 | 0.13 0.13 0.16 | 0.22 0.22 0.40 | 0.35 0.57 0.66 |

| 15 20 25 | 1/2 3/4 1 | 0.35 0.45 0.66 | 0.58 0.90 1.46 | 1.15 1.80 2.25 |

| 32 40 50 | 1-1/4 1-1/2 2 | 1.00 1.40 2.20 | 1.90 3.40 3.80 | 3.95 4.87 8.89 |

| 65 80 100 | 2-1/2 3 4 | 4.20 6.15 14.7 | 7.20 10.7 17.9 | 12.8 21.6 29.5 |

Specification of Carbon Steel Threaded Tee

| Type | Equal Tee and Reducing Tee |

| Size | 1/8″ to 4″ |

| Class | 2000, 3000, 6000, 2M, 3M, 6M |

| Grade | ASTM A105, ASTM A350 LF2, ASTM A182 F11, F22 , F91 , F5 |

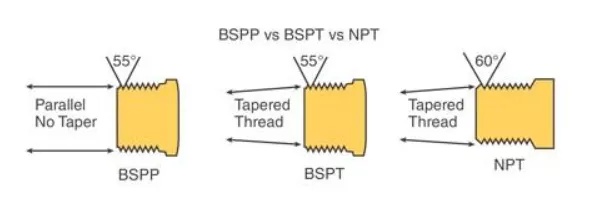

Common Thread Types of Threaded Fittings

BSPP: British Standard Pipe Parallel

BSPT: British Standard Pipe Tapered

NPT: American National Standard Pipe Tpaer

ASTM A105 Threaded Tee

ASTM A105 carbon steel threaded tees are made up of a combination of carbon, manganese, phosphorus, silicon, copper, nickel, chromium, molybdenum and vanadium. This composition makes the threaded tee strong and corrosion resistant.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

Inspection and Package

Package of Carbon Steel Threaded Tee

- Wrapping PVC on the threaded tee fitting.

- Packing stainless steel threaded tee into carton.

- Marking and recording the list for each carton.

- Putting all cartons into wooden box in line.

- Sticking shipping marking on the wooden box.

Inspection of Forged Fittings

Visual the surface of socket weld fittings such as dents, die marks, porosity.

Check the marking such as size, grade, pressure, standard.

Measure dimensions such as outside diameter, thickness, socket dimensions.

Test the chemical composition of carbon steel threaded tee.

Zizi Engineering Co Ltd is a leading industrial of ASME B16.11 Carbon steel threaded tee. Threaded pipe tee have the same inlet and outlet sizes. Carbon steel threaded tee fittings are used in different industries applications like chemical processing, oil refineries, petrochemical and many other industries.We also supply Forged Threaded Tee in customized size as per customer requirement.