Carbon steel forged pipe fittings are made from forged carbon steel material. Forging is a process that creates very strong fittings. Carbon steel is heated to molten temperatures and placed in the dies. The heated steel is then machined into the forged steel fittings.

Common carbon steel material standard include ASTM A105,ASTM A182,ASTM A350 LF2,ASTM A694 etc. Forged fittings standard including ASME B16.11, MSS-SP-79, MSS SP-83, MSS SP-95, MSS SP-97, and BS 3799 standards. They are used to build connection, between nominal bore schedule pipe and pipelines. They are supplied for extensive application range. Carbon steel forged pipe fittings, usually refer to two types of fittings: socket weld and threaded fittings. Pressure rating: Class 2000,3000 ,6000 and 9000 series.

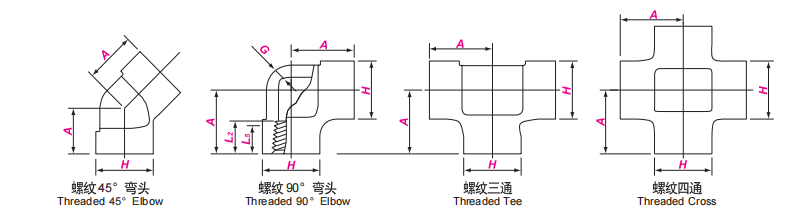

Threaded Fittings

Threaded fittings is a common used type of forged fittings in material of carbon steel. The threads can be NPT, BSPP, BSPT, PF, PT, MPT.

| Size | 1/4” to 4”( DN6 to DN100) |

| Pressure Rating | Class 2000, 3000, 6000 LBS |

| Standard | ASME B16.11, BS3799, MSS SP-79 / 83 / 85 / 97 |

| Type | Threaded Elbow, Tee, Cross, Cap, Coupling, Boss, Plug, Bushing and Union. |

| Material | ASTM A105, A350 LF2/LF3, A182 F5, F9, F11, F12, F22, F91,A694 F42, F46, F52, F60, F65 etc. |

Dimension of Threaded Carbon Steel Forged Pipe Fittings

| Nominal Size | Center-to-End | Outside Diameter of Band | Wall Thickness | Length of Thread | |||||||||||

| DN | NPS | A | H | G min | min | mim | |||||||||

| 90 Ebows Tees Crosses | 45 Elbows | ||||||||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | ||||

| 6 8 10 | 1/8 1/4 3/8 | 21 21 25 | 21 25 28 | 25 28 33 | 17 17 19 | 17 19 22 | 19 22 25 | 22 22 25 | 22 25 33 | 25 33 38 | 3.18 3.18 3.18 | 3.18 3.30 3.51 | 6.35 6.60 6.98 | 6.4 8.1 9.1 | 6.7 10.2 10.4 |

| 15 20 25 | 1/2 3/4 1 | 28 33 38 | 33 38 44 | 38 44 51 | 22 25 28 | 25 28 33 | 28 33 35 | 33 38 46 | 38 46 56 | 46 56 62 | 3.18 3.18 3.68 | 4.09 4.32 4.98 | 8.15 8.53 9.93 | 10.9 12.7 14.7 | 13.6 13.9 17.3 |

| 32 40 50 | 1-1/4 1-1/2 2 | 44 51 60 | 51 60 64 | 60 64 83 | 33 35 43 | 35 43 44 | 43 44 52 | 56 62 75 | 62 75 84 | 84 102 | 3.89 4.01 4.27 | 5.28 5.56 7.14 | 10.59 11.07 12.09 | 17.0 17.8 19.0 | 18.0 18.4 19.2 |

| 65 80 100 | 2-1/2 3 4 | 76 86 106 | 83 95 114 | 95 106 114 | 52 64 79 | 52 64 79 | 64 79 79 | 92 109 146 | 102 121 152 | 121 146 152 | 5.61 5.99 6.55 | 7.65 8.84 11.18 | 15.29 16.64 18.67 | 23.6 25.9 27.7 | 28.9 30.5 33.0 |

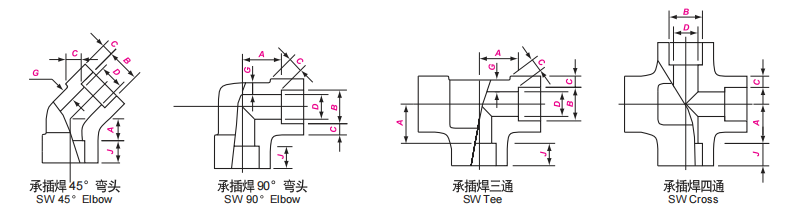

Socket Weld Fittings

Socket weld fittings are one type of high pressure forged fittings, which available in carbon steel, alloy steel, stainless steel and duplex steel. We also call it as SW.

| Size | 1/4″ to 4″ ( DN6 to DN100) |

| Pressure Rating | Class 3000, 6000, 9000 LBS |

| Standard | ASME B16.11, BS3799, MSS SP-79 / 83 / 85 / 97 |

| Type | Socket Weld Elbow, Tee, Cross, Cap, Coupling, Boss, Union, Outlet. |

| Material | ASTM A105, A350 LF2/LF3, A182 F5, F9, F11, F12, F22, F91,A694 F42, F46, F52, F60, F65 etc. |

Dimension Chart

| Nominal Size | Socket Bore Dia | Bore Dia. of Fittings | Socket Wall Thickness | Body Wall | Depth of Socket | Center to Bottom of Socket | |||||||||||||||

| D N | NPS | B | D | C | Gmin | J mim | A | ||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 90°Elbow Tee Cross | 45°Elbow | |||||||||||

| ave | min | ave | min | ave | min | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | ||||||||||

| 6 | 1/8 | 10.9 | 6.1 | 3.2 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 | 11.0 | 11.0 | 8 | 8 | ||||||

| 8 | 1/4 | 14.3 | 8.5 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 | 11.0 | 13.5 | 8 | 8 | ||||||

| 10 | 3/8 | 17.7 | 11.8 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 | 13.5 | 15.5 | 8.0 | 11.0 | ||||||

| 15 | 1/2 | 21.9 | 15.0 | 11 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.53 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 11 | 12.5 | 15.5 |

| 20 | 3/4 | 27.3 | 20.2 | 14.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 13 | 14 | 19 |

| 25 | 1 | 34 | 25.9 | 19.9 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 14.0 | 17.5 | 20.5 |

| 32 | 1-1/4 | 42.8 | 34.3 | 28.7 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 17.5 | 20.5 | 22.5 |

| 40 | 1-1/2 | 48.9 | 40.1 | 33.2 | 27.2 | 6.35 | 5.54 | 8.92 | 7.8 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 20.5 | 25.5 | 25.5 |

| 50 | 2 | 61.2 | 51.7 | 42.1 | 37.4 | 6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 25.5 | 28.5 | 28.5 |

| 65 | 2-1/2 | 73.9 | 61.2 | 8.76 | 7.62 | 7.01 | 16.0 | 41.0 | 28.5 | ||||||||||||

| 80 | 3 | 89.9 | 76.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | ||||||||||||

| 100 | 4 | 115.5 | 100.7 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | ||||||||||||

Carbon Steel Material properties

Carbon steel is often divided into two main categories: low-carbon steel and high-carbon steel. It may also contain other elements, such as manganese, phosphorus, sulfur, and silicon, which can affect its properties. Carbon steel can be easily machined and welded, making it versatile for various applications. It can also be heat treated to improve its strength, hardness, and durability.

We can supply carbon steel forged pipe fittings of different materials, such as ASTM A105, A350 LF2, A182 F5, F9, F11, F12, F22, F91,A694 F42,F46,F52,F60,F65 etc.

ASTM A105 Carbon Steel Forged Pipe Fittings

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

ASTM A182 Alloy Steel Material

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A182 F5 | MIN | 0.30 | 4.00 | 0.44 | |||||

| MAX | 0.15 | 0.60 | 0.030 | 0.030 | 0.50 | 0.50 | 6.00 | 0.65 | |

| ASTM A182 F9 | MIN | 0.30 | 0.50 | 8.00 | 0.90 | ||||

| MAX | 0.15 | 0.60 | 0.030 | 0.030 | 1.00 | 10.00 | 1.10 | ||

| ASTM A182 F12 CL1 | MIN | 0.05 | 0.30 | 0.80 | 0.44 | ||||

| MAX | 0.15 | 0.60 | 0.45 | 0.45 | 0.50 | 1.25 | 0.65 | ||

| ASTM A182 F12 CL2 | MIN | 0.10 | 0.30 | 0.10 | 0.80 | 0.44 | |||

| MAX | 0.20 | 0.80 | 0.40 | 0.40 | 0.60 | 1.25 | 0.65 |

Mechanical Properties

| MATERIAL | ASTM A182 F5 | ASTM A182 F9 | ASTM A182 F12 CL1 | ASTM A182 F12 CL2 |

| T.S (MPA) | 485 min | 585 min | 415 min | 485 min |

| Y.S (MPA) | 275 min | 380 min | 220 min | 275 min |

| EL % | 20 min | 20 min | 20 min | 20 min |

| R/A % | 35 min | 40 min | 45 min | 30 min |

| HARDNESS | 143-217 | 179-217 | 121-174 | 143-207 |

ASTM A350 LF2 Low Temperature Steel Forged Fittings

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | Nb |

| ASTM A350 LF2 | MIN | 0.60 | 0.15 | |||||||||

| MAX | 0.30 | 1.35 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 | 0.02 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A350 LF2 | 485-655 | 250 min | 22 min | 30 min | 197 max |

ASTM A694

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si |

| ASTM A694 F42 | MIN | 0.15 | ||||

| MAX | 0.30 | 1.60 | 0.025 | 0.025 | 0.35 |

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| ASTM A694 F42 | 415 min | 290 min | 20 min |

Advantage Forged Fittings

Corrosion resistant

Highly durable

Lightweight

Low maintenance

Long service life

Forged fittings are basically used for piping and tubing systems to connect and change direction of the flow that conveys liquid, gas, and occasionally solid materials.When selecting and using forged fittings, attention should be paid to their quality and performance to ensure the safety, stability, and efficiency of fluid transportation, providing reliable guarantees for fluid transportation systems in various industries.