Carbon steel buttweld fittings use seamless or welded pipe as starting material and process to the shape of elbows, tees & reducers by hot and cold forming.

China manufacturer supplies various of carbon steel buttweld fittings, they are 90 degree elbow, straight and reducing tee, concentric and eccentric reducer, cap, stub end. Why more and more people choose butt welding even if the operation is difficult?

- Leakproof and Strong

- Good Strength

- Corrosion Resistance

- Low Cost

- Universal and Economical

- Large Output

- Wild Application

Carbon Steel Buttweld Fittings Dimensions

| Standard | ASME B16.9, SH3408, HG/T21635, HG/T21631, SY/T0510 |

| Size | NPS 1/2 to 48 / DN15 to DN1200 |

| Thickness | Sch 20, 40, STD, XS, 80, 100, 120, 160, XXS |

| Surface | Painting, PE Coating, Galvanizing |

| Material | ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, A420 WPL3, WPL6, WPL9 |

Butt Weld Elbow

Carbon Steel 90 Degree Elbow

90 degree elbow change the oil and gas flow direction by 90 angle. And have long radius (LR) and short radius ( SR) types. LR means 1.5D and SR means 1D.

Carbon Steel 45 Degree Elbow

Almost same as above, just the angle is 45 degree. By the way, the weight is half of 90 degree elbow.

Size & Schedule

- NPS 1/2 ~ 60 & DN 15 ~ 1500

- Sch 20, STD, 40, XS, 80, 100, 120, 140, 160, XXS

Butt Weld Tee

Carbon Steel Equal Tee

The run pipe diameter is same to branch diameter, so we call it straight tee sometimes. It is used to connect pipelines with a pipe at a right angle with the line.

Carbon Steel Reducing Tee

From the name, we can know the three sizes are different, strictly speaking, the branch diameter is smaller than run pipe.

Size and Thickness

- NPS 1/2 ~ 48 & DN 15 ~ 1200

- Sch 10S, 20, STD, 40, XS, 80, 100, 120, 140, 160, XXS

Butt Weld Reducer

Carbon steel concentric reducer is often used inline on a vertical flow application, or if laid horizontally, as an increaser.

Carbon Steel Eccentric Reducer

An eccentric reducer is also called welded eccentric coupling. It allows for welding a large pipe to a smaller pipe with an offset center line.

Size and Thickness

- NPS 1/2 ~ 48 & DN 15 ~ 1200

- Sch 10S, 20, STD, 40, XS, 80, 100, 120, 140, 160, XXS

Specification for Carbon Steel Butt Weld Fittings

ASTM A234 – Wrought Carbon and Alloy Steel Butt Weld Fittings : This specification covers wrought carbon steel and alloy steel butt weld fittings of seamless and welded construction. This is the most common material for carbon steel butt weld fittings (specifically grade WPB) and size for seamless is up to 24”, where diameters of 24” or larger may come seamless or welded. These butt weld fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures.

ASTM A860: This specification covers wrought high-strength ferritic steel butt weld fittings of seamless and electric fusion-welded construction covered by the latest revisions of ASME B16.9 and MSS-SP-75. These butt weld fittings are for use in high-pressure gas and oil transmission and distribution systems.

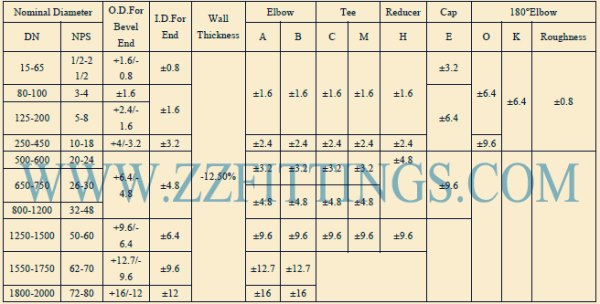

What is Tolerance for Buttweld Fittings