ZIZI ENGEERING is a supplier specializing in providing stainless steel butt weld fittings for overseas customers. With advanced production equipment and excellent service, it has gained the trust of many customers worldwide. Not long ago, we just received an order for ASTM A403 WP304H & 316H pipe fittings.

Purchase Order List

| Description of Goods | Material | Size | SCH | QTY (PCS) | |

| 1 | 90 ELBOW S10 BE ASTM A403 GR.WP304H‐WX | 304H | 28″ | S10 | 45 |

| 2 | 90 ELBOW S10 BE ASTM A403 GR.WP304H‐WX | 304H | 30″ | S10 | 52 |

| 3 | 90 ELBOW XS BE ASTM A403 GR.WP304H‐WX | 304H | 32″ | XS | 28 |

| 4 | 90 ELBOW XS BE ASTM A403 GR.WP304H‐WX | 304H | 34″ | XS | 10 |

| 5 | 90 ELBOW XS BE ASTM A403 GR.WP304H‐WX | 304H | 46″ | XS | 12 |

| 6 | 90 ELBOW S10 BE ASTM A403 Gr.WP316H‐WX | 316H | 36″ | S10 | 21 |

| 7 | ELBOW 45 20″S20 BE ASTM A403 Gr.WP304H‐WX | 304H | 20 | 20S | 16 |

| 8 | 45 ELBOW 10S BE ASTM A403 Gr.WP304H‐S | 304H | 12″ | 10S | 13 |

| 9 | ELBOW 45 46″ XS BE ASTM A403 GR.WP304H‐WX | 304H | 46″ | XS | 25 |

| 10 | ELBOW 45 34″ XS BE ASTM A403 GR.WP304H‐WX | 304H | 34″ | XS | 18 |

| 11 | ELBOW 45 32″ XS BE ASTM A403 GR.WP304H‐WX | 304H | 32″ | XS | 19 |

This customer has already received cargoes from another supplier from the same list, but they found the technical details didn’t meet their requirement , so they came to us for help.

Mainly it was because two reasons. Firstly, the description didn’t include the elbow radius in their last order, they need long radius type, so I remarked that in the PI. Secondly, the material type ASTM A403 WP304H & 316H pipe fittings are a little different from WP304/316, very rare in the market, I checked the dependable source of material before quoting to the customer, and include the cost of laboratory inspections to meet the end-user’s requirement.

Stainless Steel Elbow Material Grade

ASTM A403 standard includes several grades of austenitic stainless steel alloys, and uses the WP or CR prefix to mark the grade of steel, depending on the applicable ASTM or MSS size and rated pressure standards.

Material under this standard named as WP Grade, and for each WP grade stainless steel, several categories of pipe fittings are included, to indicate that a seamless or welded structure is used.

ASTM A403 WP304H & 316H Pipe Fittings Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A403 WP304 | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | |||

| ASTM A403 WP304L | MIN | 8.0 | 18.0 | |||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | |||

| ASTM A403 WP304H | MIN | 0.04 | 8.0 | 18.0 | ||||||

| MAX | 0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | |||

| ASTM A403 WP304N | MIN | 8.0 | 18.0 | 0.10 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.16 | ||

| ASTM A403 WP304LN | MIN | 8.0 | 18.0 | 0.10 | ||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 11.0 | 20.0 | 0.16 | ||

| ASTM A403 WP316 | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | ||

| ASTM A403 WP316L | MIN | 10.00 | 16.00 | 2.00 | ||||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | ||

| ASTM A403 WP316H | MIN | 0.04 | 10.00 | 16.00 | 2.00 | |||||

| MAX | 0.10 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | ||

| ASTM A403 WP316N | MIN | 10.00 | 16.00 | 2.00 | 0.10 | |||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | 0.16 | |

| ASTM A403 WP316LN | MIN | 10.00 | 16.00 | 2.00 | 0.10 | |||||

| MAX | 0.03 | 2.00 | 0.045 | 0.030 | 1.00 | 14.00 | 18.00 | 3.00 | 0.16 |

ASTM A403 WP304H & 316H Pipe Fittings Tensile Properties

| MATERIAL | ASTM A403 WP304 | ASTM A403 WP304L | ASTM A403 WP304H | ASTM A403 WP304N | ASTM A403 WP304LN |

| T.S (MPA) | 515 min | 485 min | 515 min | 550 min | 515 min |

| Y.S (MPA) | 205 min | 170 min | 205 min | 240 min | 205 min |

| EL % | 28 min | 28 min | 28 min | 28 min | 28 min |

| MATERIAL | ASTM A403 WP316 | ASTM A403 WP316L | ASTM A403 WP316H | ASTM A403 WP316N | ASTM A403 WP316LN |

| T.S (MPA) | 515 min | 485 min | 515 min | 550 min | 515 min |

| Y.S (MPA) | 205 min | 170 min | 205 min | 240 min | 205 min |

| EL % | 28 min | 28 min | 28 min | 28 min | 28 min |

ASTM A403 WP304L means low carbon(C≤0.03); 304H means high carbon(0.04≥C≤0.10). Because of the difference of carbon content, the 304H have a better heat and corrosive resistant, and the 304L material has a good welding performance.This is the most important difference between the three grades.

ZIZI ENGEERING can manufacture the ASTM A403 WP304H & WP316Hpipe fittings. ASTM A403 WP304L pipe fittings and ASTM A403 WP304H pipe fittings in high quality and soon delivery. If you want to know more about our pipeline products, please email us: sales@zzsteels.com

Our Supply Range

| Material Grade | ASTM A403WP304, WP304H, WP310S, WP316, WP316H etc. |

| Standard | ASME B16.9 & ANSI B16.19 |

| Dimension | 1/2 to 80 Inch / DN15 — DN2000 |

| Thickness | Sch 10S, 20, STD, 40S, 80S, 100, 120,140, 160, XXS |

| Form | Seamless and Welded Pipe Fittings |

| End Preparation | BE (Beveled End) & PE ( Plain End) |

Inspection of Stainless Steel Elbow

Visual the surface of stainless steel equal tee fittings body.

Measure dimensions. Such as outside diameter, height from end to end, wall thickness.

Check the marking:

<45 DEG LR SMLS 12″ SCH10 ASTM A403 Gr. WP304H ASME B16.9 CFG4-67>

<90 DEG LR WELDED 36″ SCH10 ASTM A403 Gr. WP316H ASME B16.9 A1234599>

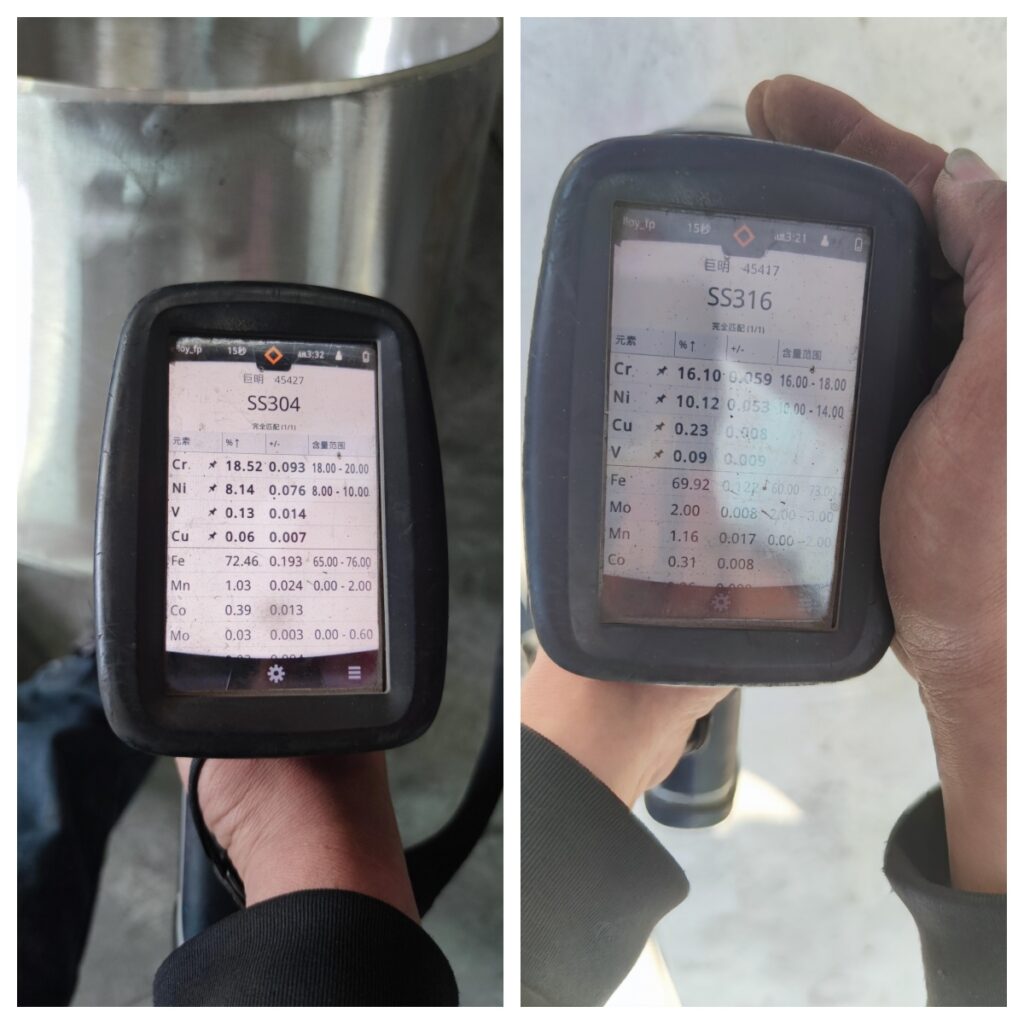

For stainless steel fittings, we also conduct PMI testing to ensure the accuracy of the material.

Butt Weld Elbow vs Socket Weld Elbow

Standard

ASME B16.9 for butt weld fittings

ASME B16.11 for socket weld fittings

Dimensions

BW : 1/2″ to 48″

SW: 1/8″ to 4″

Manufacturing

BW: Hot Forming

SW: Forging