On 10th, January, we received one inquiry from one of our regular customers. Last year this client customized a batch of 180 deg elbow in ASTM A234 WPB material. This time he need a new batch of elbows in different sizes, including 180 deg elbow and 90 deg elbow.

Inspecting the drawings provided, our engineering showed their feasibility. After discussing the detailed data of the elbows, the client placed the order in February.

Since there’re 540 pcs in total for 2 items, we made one sample for client’s confirmation at first. After client’s evaluation and confirmation, we produced the elbow in quantity.

After reviewing all the goods photos, the client agreed to arrange delivery.

Inspection photos

ASTM A234 WPB Elbow is a type of pipe fitting commonly used to change the direction of fluid flow in a piping system. It is made from carbon steel that conforms to the ASTM A234 standard, which specifies the requirements for pipe fittings made from wrought carbon steel and alloy steel.

ASTM A234 WPB Explanation

ASTM A234: This is a standard specification set by ASTM International (formerly known as the American Society for Testing and Materials) for wrought carbon steel and alloy steel fittings. It includes various fittings like elbows, tees, reducers, and caps used in pressure systems and piping.

WPB: This refers to a specific grade of carbon steel material under ASTM A234. WPB stands for Weldable (W), Pipe (P), and Grade B (B). This means the material is suitable for welding and can handle moderate pressure and temperature conditions. WPB fittings are typically used in carbon steel piping systems where medium pressure is involved.

Manufacturing Process

Forging: The elbow is forged into shape to meet the desired specifications.

Heat Treatment: Elbows are heat-treated to improve mechanical properties, especially strength and durability.

Welding: Elbows are often welded to other pipes to form a continuous pipeline. Welding procedures are crucial to ensure the joint’s strength and prevent leaks.

Non-Destructive Testing: Elbows are tested for defects using methods like X-rays or ultrasonic testing to ensure no internal or external flaws.

Specification of ASME B16.9 Elbow

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253 |

| Carbon Steel Grades | ASTM A234 WPB/WPC, A420 WPL6, A860 WPHY 42 / 46 / 56 / 60 / 65 |

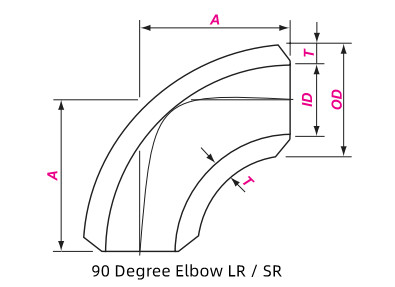

90 Degree Elbow Dimensions

| DN | NPS | OD | A | |

| LR | SR | |||

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1-1/4 | 42.2 | 48 | 32 |

| 40 | 1-1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2-1/2 | 73.0 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3-1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273.0 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559.0 | 838 | 559 |

| 600 | 24 | 610.0 | 914 | 610 |

| 650 | 26 | 660.0 | 991 | 660 |

| 700 | 28 | 711.0 | 1067 | 711 |

| 750 | 30 | 762.0 | 1143 | 762 |

| 800 | 32 | 813.0 | 1219 | 813 |

| 850 | 34 | 864.0 | 1295 | 864 |

| 900 | 36 | 914.0 | 1372 | 914 |

| 950 | 38 | 965.0 | 1447 | 965 |

| 1000 | 40 | 1016.0 | 1524 | 1016 |

| 1050 | 42 | 1067.0 | 1600 | 1067 |

| 1100 | 44 | 1118.0 | 1676 | 1118 |

| 1150 | 46 | 1168.0 | 1753 | 1168 |

| 1200 | 48 | 1219.0 | 1829 | 1219 |

| 1300 | 52 | 1321.0 | 1981 | 1321 |

| 1400 | 56 | 1422.0 | 2134 | 1422 |

| 1500 | 60 | 1524.0 | 2286 | 1524 |

| 1600 | 64 | 1626.0 | 2438 | 1626 |

| 1700 | 68 | 1727.0 | 2591 | 1727 |

| 1800 | 72 | 1829.0 | 2743 | 1829 |

| 1900 | 76 | 1930.0 | 2896 | 1930 |

| 2000 | 80 | 2032.0 | 3048 | 2032 |

Key Characteristics of ASTM A234 WPB Elbow

Material: WPB fittings are made of carbon steel, commonly using materials like A106 Grade B or A53 Grade B steel, offering good strength, weldability, and pressure tolerance.

Temperature Range: ASTM A234 WPB fittings are suitable for use in systems operating within the temperature range of -29°C to 425°C (-20°F to 800°F).

Strength: The tensile strength of WPB fittings is typically around 485 MPa (70 ksi) minimum, ensuring they can withstand standard operating pressures.

Corrosion Resistance: While WPB elbows offer good resistance in non-extreme environments, they are generally not suitable for highly corrosive or acidic environments. They are commonly used in systems carrying water, oil, and natural gas.

Applications: Commonly used in pipelines for oil and gas, chemical plants, power generation, and HVAC systems.

Common Applications

Oil and Gas Industry: For the transportation of oil, natural gas, and water pipelines.

Chemical and Petrochemical Plants: Used in fluid and gas transport systems, especially in medium-pressure applications.

Power Plants: For steam, water, and gas transport systems.

HVAC Systems: Used for systems requiring a change in fluid flow direction.

Common Sizes and Angles

Angles: The most common elbow angles are 45°, 90°, and 180°. These are used to change the direction of the pipeline in various ways.

Pipe Sizes: ASTM A234 WPB elbows come in a wide range of sizes, from small-diameter pipes to large-diameter pipes, depending on the project’s requirements.