ASTM A234 is standard specification for wrought carbon steel & alloy steel pipe fittings which covers seamless and welded types.

They are available in latest revision of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97. Also widely used in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. The grades are ASTM A234 WPB, WPC, WP5, WP9, WP91, WP11, WP12 and WP22.

What is WPB Meaning?

W = WELDABLE / wrought

P = RELATED TO P NUMBER OF ALLOY MATERIAL

B = REFER TO MINIMUM YIELD OF MATERIAL

ASTM A234 WPB Pipe Fittings

Heat Treatment

Hot-formed A234 WPB and WPC pipe fittings finished at temperature in excess of 1800°F[980°C] shall be subsequently annealed, normalized, or normalized and tempered.

The A234 WPB butt-welding pipe fittings include elbow, bend, tee, reducer, end cap, cross, lap joint stub end and nipple.

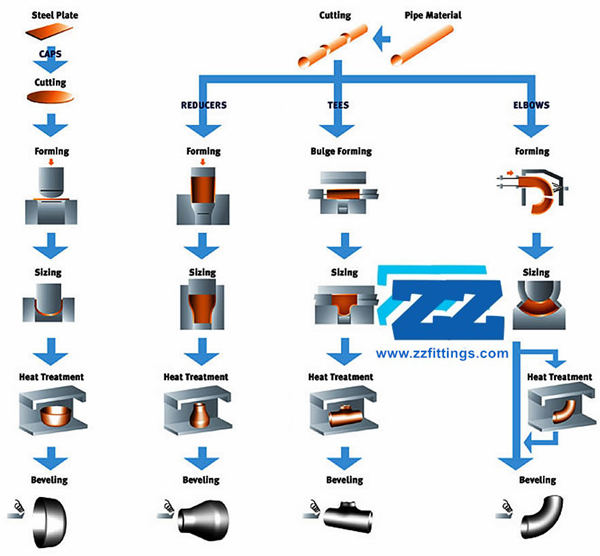

Manufacturing

ASTM A234 carbon steel pipe fittings may be made from seamless pipes, welded pipes or plates by shaping operations of pressing, piercing, extruding, bending, fusion welding, machining, or by a combination of two or more these operations. All welds including welds in tubular products from which fittings are made shall be made in accordance with ASME Section IX. Post-weld heat treatment at 1100 to 1250°F[595 to 675°C] and radiographic examination shall be performed after the welding process.

ASTM A234 Properties

Chemical Properties

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| ASTM A234 WPB | 0.3 | 0.1 min | 0.29-1.06 | 0.05 | 0.058 | 0.4 | 0.4 | 0.15 |

| ASTM A234 WPC | 0.35 | 0.1 min | 0.29-1.06 | 0.05 | 0.058 | 0.4 | 0.4 | 0.15 |

| ASTM A234 WP5 CL1 | 0.15 | 0.5 | 0.3-0.6 | 0.04 | 0.03 | 4-6 | 0.44-0.65 | |

| ASTM A234 WP5 CL3 | 0.15 | 0.5 | 0.3-0.6 | 0.04 | 0.03 | 4-6 | 0.44-0.65 | |

| ASTM A234 WP9 CL1 | 0.15 | 1 | 0.3-0.6 | 0.03 | 0.03 | 8-10 | 0.9-1.1 | |

| ASTM A234 WP9 CL3 | 0.15 | 1 | 0.3-0.6 | 0.03 | 0.03 | 8-10 | 0.9-1.1 | |

| ASTM A234 WP91 | 0.08-0.12 | 0.2-0.5 | 0.3-0.6 | 0.02 | 0.01 | 8-9.5 | 0.4 | 0.85-1.05 |

| ASTM A234 WP11 CL1 | 0.05-0.15 | 0.5-1 | 0.3-0.6 | 0.03 | 0.03 | 1-1.5 | 0.44-0.65 | |

| ASTM A234 WP11 CL2 | 0.05-0.2 | 0.5-1 | 0.3-0.8 | 0.04 | 0.04 | 1-1.5 | 0.44-0.65 | |

| ASTM A234 WP11 CL3 | 0.05-0.2 | 0.5-1 | 0.3-0.8 | 0.04 | 0.04 | 1-1.5 | 0.44-0.65 | |

| ASTM A234 WP12 CL1 | 0.05-0.2 | 0.6 | 0.3-0.8 | 0.045 | 0.045 | 0.8-1.25 | 0.44-0.65 | |

| ASTM A234 WP12 CL2 | 0.05-0.2 | 0.6 | 0.3-0.8 | 0.045 | 0.045 | 0.8-1.25 | 0.44-0.65 | |

| ASTM A234 WP22 CL1 | 0.05-0.15 | 0.5 | 0.3-0.6 | 0.04 | 0.04 | 1.9-2.6 | 0.87-1.13 | |

| ASTM A234 WP22 CL3 | 0.05-0.15 | 0.5 | 0.3-0.6 | 0.04 | 0.04 | 1.9-2.6 | 0.87-1.13 |

Mechanical Properties

| Grade | T.S (min) | Y.S (min) | EL (min) | HB (max) |

| ASTM A234 WPB | 415-655 (Mpa) | 240 (Mpa) | 22 % | 197 |

| ASTM A234 WPC | 485-655 (Mpa) | 275 (Mpa) | 22 % | 197 |

| ASTM A234 WP5 CL1 | 415-585 (Mpa) | 205 (Mpa) | 22 % | 217 |

| ASTM A234 WP5 CL3 | 520-690 (Mpa) | 310 (Mpa) | 22 % | 217 |

| ASTM A234 WP9 CL1 | 415-585 (Mpa) | 205 (Mpa) | 22 % | 217 |

| ASTM A234 WP9 CL3 | 520-690 (Mpa) | 310 (Mpa) | 22 % | 217 |

| ASTM A234 WP91 | 585-760 (Mpa) | 415 (Mpa) | 20 % | 248 |

| ASTM A234 WP11 CL1 | 415-585 (Mpa) | 205 (Mpa) | 22 % | 197 |

| ASTM A234 WP11 CL2 | 485-655 (Mpa) | 275 (Mpa) | 22 % | 197 |

| ASTM A234 WP11 CL3 | 520-690 (Mpa) | 310 | 22 % | 197 |

| ASTM A234 WP12 CL1 | 415-585 (Mpa) | 220 | 22 % | 197 |

| ASTM A234 WP12 CL2 | 485-655 (Mpa) | 275 | 22 % | 197 |

| ASTM A234 WP22 CL1 | 415-585 (Mpa) | 205 | 22 % | 197 |

| ASTM A234 WP22 CL3 | 520-690 (Mpa) | 310 | 22 % | 197 |