Outlet is a common forged pipe fitting commonly used for connecting pipes and equipment. ASTM A105 threaded outlet is our company’s advantageous product and occupies a certain proportion in daily export products. Recently, we received an order for ASTM A105 threaded outlet from Indonesia customer. The diameter of the outlet in this order requires 1/2″X 2″ and 1″X2″, with a pressure of 3000LBS.

Outlets are usually connected to the main pipe by welding, while connections to branch pipes or other pipes (such as short pipes, plugs, etc.), instruments, and valves can be made in three types: welding, socket, or threaded connections. This diversified connection method enables branch pipe holders to adapt to different pipeline systems and installation requirements.

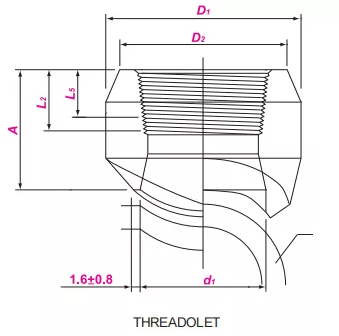

A threaded outlet is an efficient and reliable pipeline connection component widely used in various industrial pipeline systems. Its base is the same as weldolet, but the branch connection uses threaded connections and does not require welding. This design method makes the installation and maintenance process of threaded branch pipe holders more convenient and efficient, especially in environments or scenarios where welding operations are difficult, the advantages of threaded branch pipe holders are more obvious.

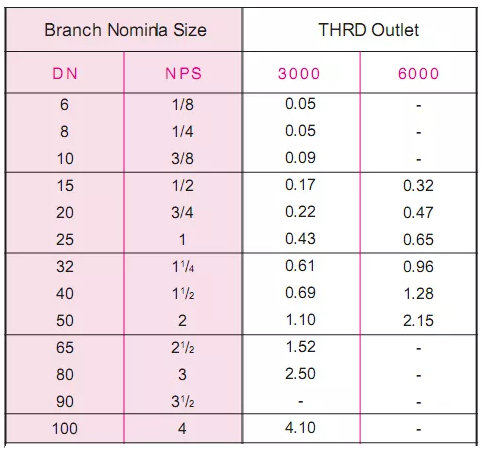

Dimension of ASTM A105 Threaded Outlet

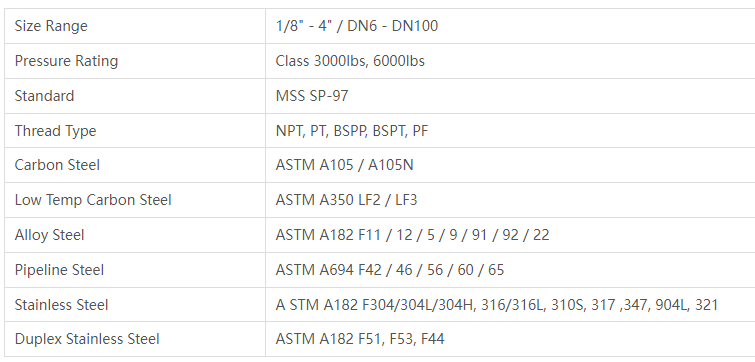

The conventional threaded outlet diameter is between 1/8 inch to 4 inch; Common pressure levels include 3000LBS (SCH XS) and 6000LBS (SCH 160). The raw materials include various materials such as carbon steel, stainless steel, alloy steel, low-temperature steel, etc.

Material Characteristics

The ASTM A105 threaded outlet body is forged from high-quality carbon steel material, ensuring its strength and corrosion resistance, and can adapt to various harsh working environments. ASTM A105 is a material standard for carbon steel forgings for pipeline components developed by the American Society for Testing and Materials (ASTM). The chemical composition of ASTM A105 has strict regulations to ensure its specific physical and chemical properties.

Chemical Composition

| C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | |

| MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

In terms of mechanical properties, the ASTM A105 standard specifies key indicators such as tensile strength, yield strength, elongation, and impact toughness. These indicators ensure the reliability and durability of A105 steel in pipeline systems.

Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

In addition, the ASTM A105 standard also puts forward requirements for the surface quality of forgings, requiring them to be smooth and flat, without cracks, stains, and obvious surface defects. This strict control of surface quality helps to improve the sealing and safety of pipeline systems.

Application

ASTM A105 threaded outlet is mainly used for reinforcing branch pipe connections and can replace traditional branch pipe connection types such as reducing tees, reinforcing plates, and reinforced pipe sections. It has outstanding advantages such as safety and reliability, cost reduction, simple construction, improved medium flow channels, series standardization, and convenient design and selection. Especially in high-pressure, high-temperature, large-diameter, and thick walled pipelines, their use is becoming increasingly widespread, gradually replacing traditional branch connection methods.

Easy to install

High strength and durability

Sealability

Wide applicability

Reduce project costs

MSS SP-97 Threaded Outlet

The ASTM A105 threaded outlet is manufactured according to the American standard MSS SP-97 production standard, which provides clear specifications for the design, manufacturing, and installation of threaded outlet, which is conducive to product interchangeability and universality, and improves the convenience of engineering design and construction. MSS SP-97 is the production standard for American standard forged branch pipe fittings. According to this standard, various types of branch pipe fittings can be designed and manufactured, such as butt welded outlet, threaded outlet, socket outlet etc. The MSS SP-97 standard also specifies the end types of export fittings, which should comply with the requirements of ASME B16.25 (butt welding ends) or ASME B16.11 (socket welding and threaded ends).

Overall, MSS SP-97 provides comprehensive and standardized guidance for the design and manufacturing of forged branch pipe sockets, ensuring their quality and performance, enabling them to play an important role in pipeline systems.

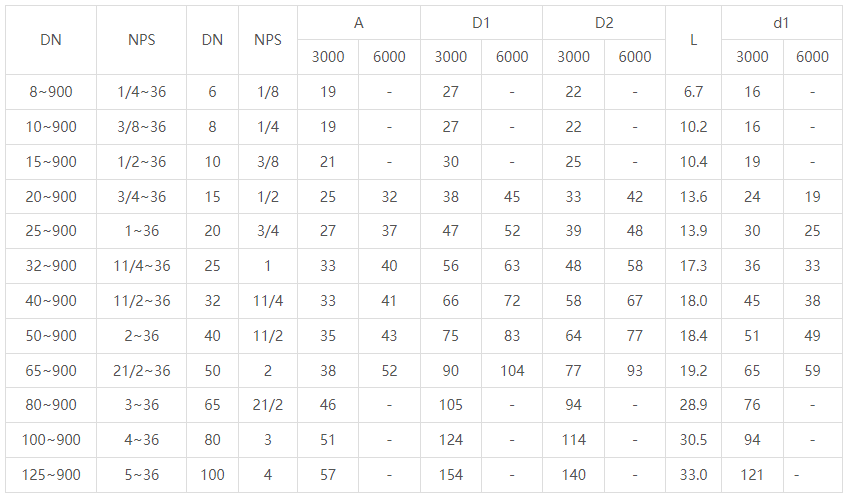

Dimension Of MSS SP-97 Threaded Outle

ASTM A105 threaded outlet Weight List