Last year, before Chinese new spring festival began, Mr Patrick from Côte d’Ivoire urgently needed a batch of ASTM A105 Slip on Flange

As the Spring Festival is approaching, most factories in China have entered holiday mode, and logistics and transportation are also facing challenges. After much coordination, we successfully produced and shipped these products within 7 days.

After receiving the goods, he expressed high appreciation for our quick response and efficient logistics, said he would continue to cooperate in the future, and planned to expand the scale of purchases in the new year.

The inspection photos are as follows:

ASTM A105 Slip on Flanges Specification

ASTM A105 Slip On Flange (SO flange) is a carbon steel Slip On Flange manufactured according to ASTM A105 standard and suitable for high temperature and high pressure pipeline systems. Its installation method is to put the flange directly on the pipe and then fix it with fillet welding. It is usually used in low pressure and non-critical applications.

ASTM A105 is the standard specification for carbon steel forging and is used in different piping applications. The ASTM A105 Carbon Steel Slip on Flanges is used in various fittings and valves with high-temperature services in a pressure system.

| Sealing Face | RF, FF, FTJ |

| Size Range | 1/2″ – 24″ / DN15 – DN600 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ANSI / ASME B16.5, EN1092-1 |

| Carbon Steel | ASTM A105 / A105N |

A105 Flange Welding

These components can be welded. Welding procedures must comply with ASME Boiler and Pressure Vessel Code Section IX.

A105 Flange Heat Treatment

Heat treatment is not a mandatory requirement except for flanges above Class 300, flanges of special design where the design pressure or design temperature are not known and for items over 4” NPS and above Class 300. When heat treatment is required, annealing, normalizing, normalize and temper, normalize and quench and tempering shall be the applied methods.

A105 Flange Forging

This alloy is forged at between 1,700 degrees Fahrenheit and 2,200 degrees Fahrenheit, followed by quenching and tempering.

A105 Flange Annealing

Forged parts are allowed to cool to below 1,000 degrees Fahrenheit before reheating to between 1,550 degrees Fahrenheit and 1,700 degrees Fahrenheit. Slow furnace cooling follows.

ASTM A105 Slip On Flanges Chemical Compostion

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | MIN | 0.60 | 0.10 | ||||||||

| MAX | 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

ASTM A105 Slip On Flanges Mechanical Properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | R/A % | HARDNESS |

| ASTM A105 | 485 min | 250 min | 22 min | 30 min | 197 max |

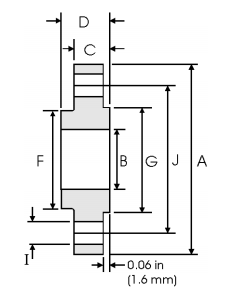

Slip-on Flange Dimensions

Class 150 lb Slip-on Flange Dimensions & Weight

| NPS | A | B | C | D | F | G | H | I | J | W |

| inch | inch | inch | inch | inch | inch | No. of Holes | inch | inch | kg/pc | |

| mm | mm | mm | mm | mm | mm | mm | mm | |||

| 1/2 | 3.500 | 0.880 | 0.440 | 0.620 | 1.190 | 1.380 | 4 | 0.620 | 2.380 | 0.39 |

| 88.90 | 22.40 | 11.20 | 15.70 | 30.20 | 35.10 | 15.70 | 60.45 | |||

| 3/4 | 3.880 | 1.090 | 0.500 | 0.620 | 1.500 | 1.690 | 4 | 0.620 | 2.750 | 0.56 |

| 98.60 | 27.70 | 12.70 | 15.70 | 38.10 | 42.90 | 15.70 | 69.85 | |||

| 1 | 4.250 | 1.360 | 0.560 | 0.690 | 1.940 | 2.000 | 4 | 0.620 | 3.120 | 0.78 |

| 108.0 | 34.50 | 14.20 | 17.50 | 49.30 | 50.80 | 15.70 | 79.25 | |||

| 1-1/4 | 4.620 | 1.700 | 0.620 | 0.810 | 2.310 | 2.500 | 4 | 0.620 | 3.500 | 1.03 |

| 117.3 | 43.20 | 15.70 | 20.60 | 58.70 | 63.50 | 15.70 | 88.90 | |||

| 1-1/2 | 5.000 | 1.950 | 0.690 | 0.880 | 2.560 | 2.880 | 4 | 0.620 | 3.880 | 1.32 |

| 127.0 | 49.50 | 17.50 | 22.40 | 65.00 | 73.15 | 15.70 | 98.60 | |||

| 2 | 6.000 | 2.440 | 0.750 | 1.000 | 3.060 | 3.620 | 4 | 0.750 | 4.750 | 2.06 |

| 152.4 | 62.00 | 19.10 | 25.40 | 77.70 | 91.90 | 19.10 | 120.7 | |||

| 2-1/2 | 7.000 | 2.940 | 0.880 | 1.120 | 3.560 | 4.120 | 4 | 0.750 | 5.500 | 3.28 |

| 177.8 | 74.70 | 22.40 | 28.40 | 90.40 | 104.6 | 19.10 | 139.7 | |||

| 3 | 7.500 | 3.570 | 0.940 | 1.190 | 4.250 | 5.000 | 4 | 0.750 | 6.000 | 3.85 |

| 190.5 | 90.70 | 23.90 | 30.20 | 108.0 | 127.0 | 19.10 | 152.4 | |||

| 3-1/2 | 8.500 | 4.070 | 0.940 | 1.250 | 4.810 | 5.500 | 8 | 0.750 | 7.000 | 4.81 |

| 215.9 | 103.4 | 23.90 | 31.75 | 122.2 | 139.7 | 19.10 | 177.8 | |||

| 4 | 9.000 | 4.570 | 0.940 | 1.310 | 5.310 | 6.190 | 8 | 0.750 | 7.500 | 5.30 |

| 228.6 | 116.1 | 23.90 | 33.30 | 134.9 | 157.2 | 19.10 | 190.5 | |||

| 5 | 10.00 | 5.660 | 0.940 | 1.440 | 6.440 | 7.310 | 8 | 0.880 | 8.500 | 6.07 |

| 254.0 | 143.8 | 23.90 | 36.60 | 163.6 | 185.7 | 22.40 | 215.9 | |||

| 6 | 11.00 | 6.720 | 1.000 | 1.560 | 7.560 | 8.500 | 8 | 0.880 | 9.500 | 7.45 |

| 279.4 | 170.7 | 25.40 | 39.60 | 192.0 | 215.9 | 22.40 | 241.3 | |||

| 8 | 13.50 | 8.720 | 1.120 | 1.750 | 9.690 | 10.62 | 8 | 0.880 | 11.75 | 12.1 |

| 342.9 | 221.5 | 28.40 | 44.50 | 246.1 | 269.7 | 22.40 | 298.5 |

Advantages

Cost-Effectiveness:

Slip on flanges are generally less expensive than weld neck flanges.2 This makes them a budget-friendly option for many projects.

Ease of Installation:

Their design allows them to “slip” onto the pipe, simplifying the alignment process.3 This reduces installation time and labor costs.

Simplified Alignment:

The ease of alignment during installation is a significant advantage, particularly in field installations where precision can be challenging.

Versatility:

ASTM A105 carbon steel is a versatile material suitable for a wide range of applications, especially those involving moderate-pressure and high-temperature conditions.4

Availability:

These types of flanges are widely available from many different suppliers.