Carbon steel forged fittings and flanges are prevalent and common used in industries, the representative material grade is ASTM A105 and A350 LF2/LF3.

They include threaded fittings and socket weld fittings which use in pressure system at ambient and high temperature service. Their specifications cover in standard MSS, ASME and API.

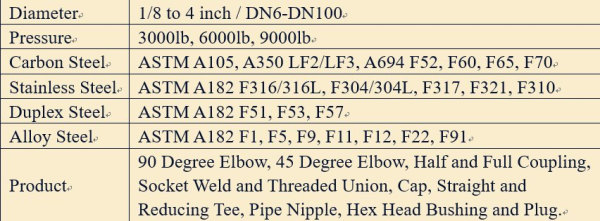

ASTM A105 Threaded Fittings

Carbon Steel ASTM A105 threaded Forged Fittings are low Carbon, Manganese and Silicon added fittings which are usable for non-critical yet pressure applications, like refrigeration fittings, that work at constant temperatures. Only fully killed carbon steel material is used for forging. This material can be in shape of a bar or in shape of the ingot to meet various forging requirement. They offer maximum machinability and weldability.

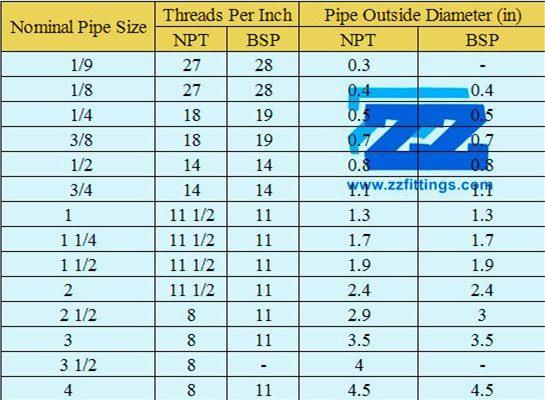

Thread Types and Sizes

NPT, PT, BSPP and BSPT

Using Go/no go gauge to inspect the thread.

ASTM A105 Socket Weld Fittings

Carbon steel ASTM A105 socket weld forged fittings are usually “normalized” heat treatment, devoid of any internal stresses and thus having superior performances.

Why Use Socket Weld Fittings

Forged socket weld fittings have uniform grain structure which makes them suitable for pressure piping in the steam and power systems. And their welding procedures are complied with ASME Boiler and pressure vessel code section IX.

ASME B16.11 Dimensions of Forged Fittings

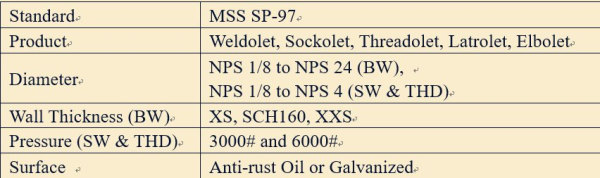

MSS SP 97 Forged Fittings Dimensions

MSS SP-97 forged fittings are integrally reinforced branch outlet fittings with socket weld end, threaded end and butt weld end. We use electro-polished to remove free iron in order to provide a high-quality finish to ensure them have the highest degree of corrosion resistance.

ASTM A105 Chemical Composition

| C | Mn | P | S | Si |

| 0.15 max | 0.6-1.05 | 0.035 | 0.04 | 0.1 min |

ASTM A105 Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

| 485 (Mpa) | 250 (Mpa) | 30 (%) |