On December 17, 2024, we received an inquiry from a Canadian customer. The inquiry product this time was a 34-inch Bend made of API 5LX52. We have cooperated with this customer on large-size elbows many times before, and we have a trusting cooperative relationship with each other.

This customer has very strict requirements on the quality of the goods. The customer purchased a 34 inch 45 degree bend, and asked us to produce a 34 inch 20 degree bend for destruction test.

Due to the smooth cooperation before, we quickly received the customer’s purchase order. After the production was completed, we provided the customer with the destruction test report, heat treatment report, hardness test report, magnetic particle test report, chemical composition test report and MTC, and shipped after the customer’s approval.

34 Inch 20-Degree Bend Inspection Photo

34 Inch 45-Degree Bend Inspection Photo

API 5L X52 is a steel grade under the API 5L standard, which covers seamless and welded steel pipes for the transmission of oil, gas, and fluids. The X52 grade indicates a minimum yield strength of 52,000 psi (360 MPa). When referring to a bend, it means a pipe section that has been curved or bent to change the pipeline direction while maintaining strength and integrity.

What is a Bend in Piping?

A steel pipe bend in piping refers to a curved section of a pipe used to change the direction of flow within a piping system. Unlike standard elbows, which have fixed angles, bends can have a custom radius and angle, offering more flexibility in design.

90 Degree Pipe Bend Specification

| Size Range | 1/2″ – 48″ / DN15 – 1200 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) |

| Standard | ASME B36.10 / ASME B36.19 / ASME B16.49 |

| Carbon Steel Material | ASTM A106B / A53B, API 5L B / X42 / X46 / X52 / X56 / X60 / X65 / X70, A333 GR 6 |

| Alloy Steel Material | ASTM A335 P11 / P12 / P22 / P 5 / P9 / P91 / P92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Material | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

API 5L X52 Bend Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | V | Nb | Ti |

| API 5L X42 | MIN | ||||||||

| MAX | 0.160 | 1.650 | 0.02 | 0.01 | 0.450 | 0.07 | |||

| API 5L X52 PSL1 | MIN | ||||||||

| MAX | 0.28 | 1.40 | 0.030 | 0.030 | |||||

| API 5L X52 PSL2 | MIN | 0.10 | |||||||

| MAX | 0.18 | 1.50 | 0.025 | 0.015 | 0.45 | 0.05 | 0.05 | 0.04 |

API 5L X52 Bend Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) |

| API 5L X52 PSL1 | 460min | 360min |

| API 5L X52 PSL2 | 460-760 | 360-530 |

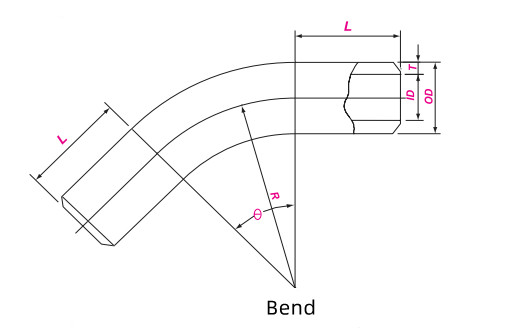

API 5L X52 Bend Radius Drawing and Dimensions

| Bend Radius | R≥3OD(OD is outside diameter of pipe) |

| Bend Angle | According to the specification of design documentation. |

| Tangent Length | Per standard or specified length in the design documentation,or both straight lengths are 500mm. |

| Outside Diameter | OD≤1200mm |

| Wall Thickness | According to the specification of design documentation. |

| Bevel at Ends | According to the bevel ends of BW fiftings or per specification of design documentation. |

3D Bend 90 Degree Weight Chart in KG

| DN | NPS | Sch20 | Sch30 | STD | Sch40 | Sch60 | XS | Sch80 | Sch100 | Sch120 | Sch160 | XXS |

| 20 | 0.14 | 0.17 | 0.17 | 0.22 | 0.22 | 0.29 | 0.36 | |||||

| 25 | 1 | 0.29 | 0.33 | 0.33 | 0.43 | 0.43 | 0.56 | 0.72 | ||||

| 32 | 1¼ | 0.47 | 0.56 | 0.56 | 0.48 | 0.48 | 0.92 | 1.28 | ||||

| 40 | 1½ | 0.70 | 0.80 | 0.80 | 1.07 | 1.07 | 1.43 | 1.88 | ||||

| 50 | 2 | 1.18 | 1.43 | 1.43 | 1.97 | 1.97 | 2.92 | 3.53 | ||||

| 65 | 2½ | 2.64 | 2.83 | 2.83 | 3.75 | 3.75 | 4.90 | 6.70 | ||||

| 80 | 3 | 3.92 | 4.47 | 4.47 | 6.04 | 6.04 | 8.45 | 11.0 | ||||

| 90 | 3½ | 5.27 | 6.26 | 6.26 | 8.60 | 8.60 | ||||||

| 100 | 4 | 6.80 | 8.47 | 8.47 | 11.8 | 11.8 | 14.9 | 17.7 | 21.6 | |||

| 125 | 5 | 14.3 | 14.3 | 20.4 | 20.4 | 26.5 | 32.3 | 37.8 | ||||

| 150 | 6 | 22.3 | 22.3 | 33.6 | 33.6 | 42.8 | 53.4 | 62.6 | ||||

| 200 | 8 | 35.1 | 38.8 | 44.8 | 44.8 | 56.0 | 68.1 | 68.1 | 80.0 | 95.3 | 117 | 114 |

| 250 | 10 | 55.0 | 67.2 | 79.4 | 79.4 | 107 | 107 | 126 | 151 | 175 | 227 | 204 |

| 300 | 12 | 78.5 | 103 | 117 | 126 | 172 | 154 | 209 | 252 | 295 | 377 | 295 |

| 350 | 14 | 125 | 150 | 150 | 174 | 234 | 198 | 292 | 359 | 414 | 519 | |

| 400 | 16 | 164 | 196 | 196 | 260 | 337 | 260 | 429 | 517 | 604 | 770 | |

| 450 | 18 | 208 | 290 | 249 | 369 | 488 | 330 | 604 | 734 | 862 | 1089 | |

| 500 | 20 | 309 | 409 | 309 | 483 | 653 | 409 | 819 | 1005 | 1163 | 1487 | |

| 550 | 22 | 374 | 496 | 374 | 852 | 496 | 1083 | 1307 | 1526 | 1947 | ||

| 600 | 24 | 446 | 663 | 446 | 807 | 1123 | 591 | 1397 | 1731 | 2023 | 2554 |

API 5L X52 Bend Applications

✔ Oil & Gas Pipelines – Used in long-distance pipelines for transporting hydrocarbons.

✔ Petrochemical & Refinery Plants – For fluid transfer between units.

✔ Power Plants – Steam and water pipelines.

✔ Water Transportation – Municipal and industrial water supply lines.