Alloy Straight Couplings Company

It is common to use alloy steel straight couplings to connect pipes in same diameters because of their excellent properties, durable lives and low cost. They are short tubes with socket weld end or threaded end. Our company can meet your corrosion resistance requirement by our quality product. It is no problem for them to working in High-Temperature conditions, so you can use them in heating exchangers, incinerators and food processing industries. Those forgings are one of our most popular products.

Pipe Couplings Types

- Straight Couplings and Reducing Couplings

- BSP and NPT Pipe Couplings

- Socket Weld Coupling and Threaded Couplings

- Full and Half Couplings

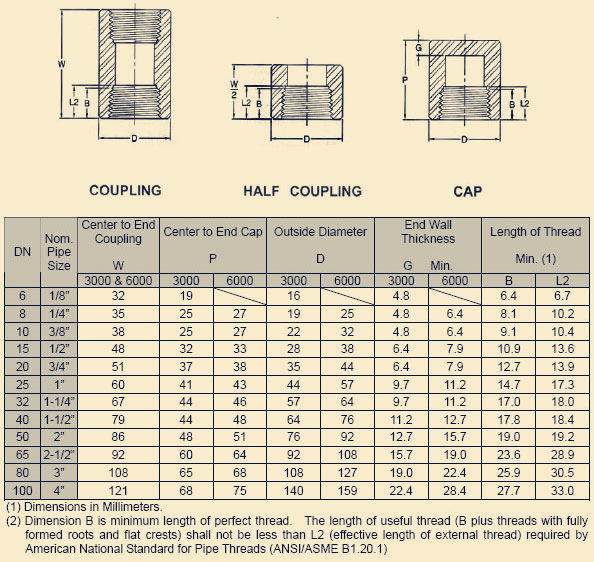

Threaded Couplings Dimensions

Straight Threaded Couplings Dimensions

Alloy Steel Forged Fittings

Specification

| Standard | ASME B16.11/BS3799 |

| Diameter | 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Threaded Couplings Material | ASTM A182 F1, F5, F9, F11, F22, F91 |

| Pressure Rating | 3000 LB, 6000 LB, 9000 LB |

| Connection Type | Socket Weld and Threaded |

Inspection of Alloy Steel Threaded Couplings

Zizi Engineering manufacture and export alloy steel straight couplings in all kind of dimensions and types. Our QA and QC will check the surface of fittings with hands and eyes, measure dimensions of each part with professional measurement tools. The chemical composition and mechanical properties must keep in line with standards.

Alloy Steel ASTM A182 Forged Fittings

Socket Weld Fittings Types

90 Degree Socket Weld Elbows, 45 Degree Socket Weld Elbows, Straight and Reducer Couplings, Full and Half Couplings, Equal Tees, Reducing Tees, Socket Weld Cross, Caps, Outlets and Unions.

Threaded Fittings Types

90 Degree Threaded Elbows, 45 Degree Threaded Elbows, Threaded Tees, Straight and Reducer Couplings, Full and Half Couplings, Swaged Nipple, Threaded Caps, Plugs, Bushings, Outlets and Nipples.